Page 1 of 3

Rifled copper barrel

Posted: Sat Aug 16, 2008 2:33 pm

by al-xg

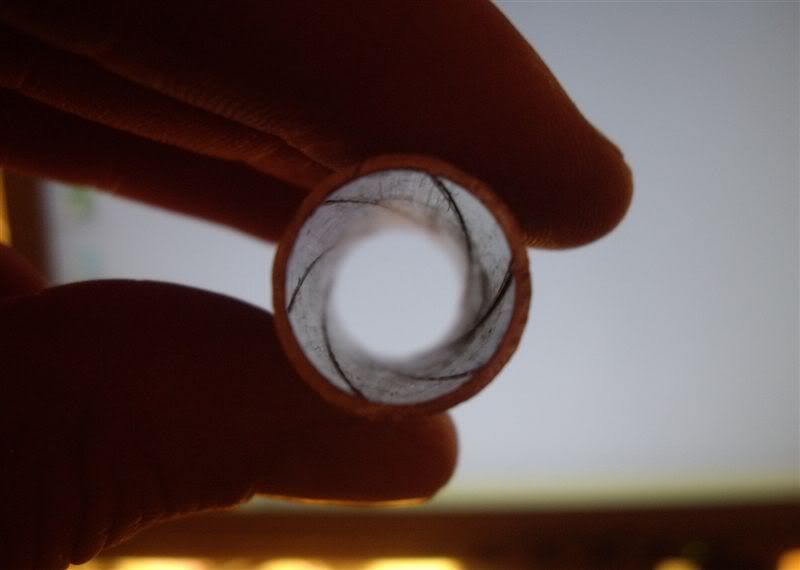

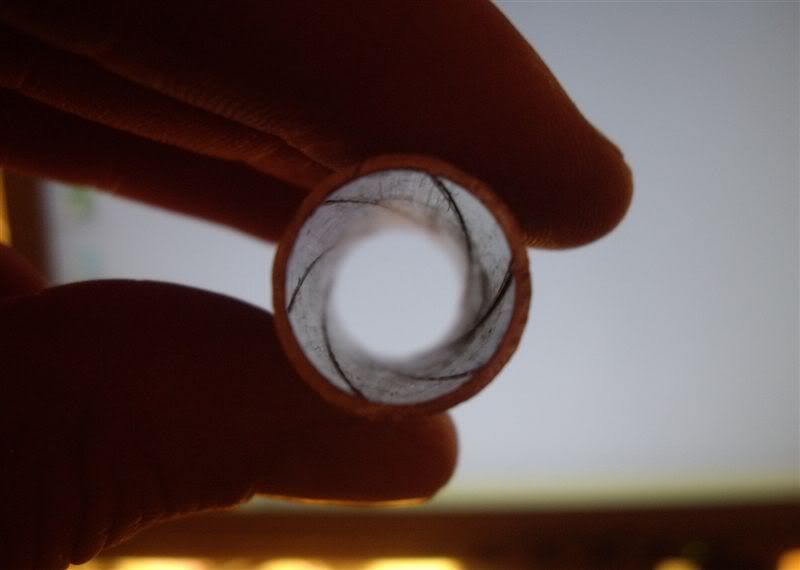

This is 16mm OD copper (~14mm ID) I experimented on, rifled at 1 turn per 8 inches (20cm).

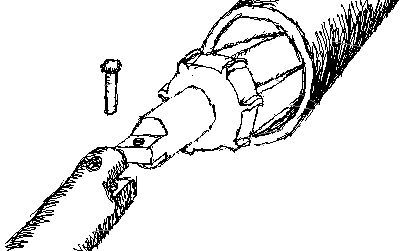

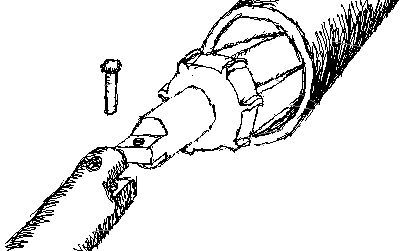

I used a homemade tool made from a steel hex head bolt.

I sets its own rotation when pulled through the barrel and cuts and endents the 6 grooves at the same time.

I then made a second tool, with a 1 turn per 16 inches (40cm) twist rate and rifled a 70cm barrel.

I had to use the first spudgun I made in order to test it, as my newer canons are all out of order.

So this spudgun has a 1/2" ballvalve as a main valve, and a 70cm*14mm copper rifled barrel, with no porting.

I fired a few

14*55mm potato slugs, at various pressures up to 20bar(290psi).

As a result I get

round impact holes 28m(~84ft) away.

Its been a while since I've shot potato slugs, but I seem to remember them tumbling alot sooner, especially with

20bar and no porting.

When fired at an angle, the slugs fly straight and as they loose speed start going in corkscrew motion wider and wider until they hit the ground.

But they don't seem to tumble.

Tool picks:

Posted: Sat Aug 16, 2008 2:36 pm

by MaxuS the 2nd

My god, someone actually managed to do it.

Great Work!

Although the walls of that copper pipe do look alot thicker than the stuff in the Uk and USA.

Posted: Sat Aug 16, 2008 2:45 pm

by al-xg

Its just 1mm and would be the same as UK copper, you could get it from BES if you wanted, but 15mm would work just as well.

I don't think the grooves have to be very deep, .22 barrels are a good example (altough I understand, that larger calibers require deeper grooves).

But the projectiles spin, when shot, when pushed through the barrel, even when blown through so I guess its good enough.

In the first attempts I made, the tool actualy made the grooves visible on the outside of the pipe, that might weaken it quite a bit, but I think it's still ok for use as a barrel at regular spudgun pressures.

Posted: Sat Aug 16, 2008 2:49 pm

by SpudFarm

i love you! *kisses*

that is just the best thing i have seen!

i have to try that!

PICS OF THE TOOL NEEDED

Posted: Sat Aug 16, 2008 2:55 pm

by hyldgaard

This post is WORTHLESS without pics of the tool

very nice job, will definately have to try that

Re: Rifled copper barrel

Posted: Sat Aug 16, 2008 3:08 pm

by Ragnarok

al-xg wrote:When fired at an angle, the slugs fly straight and as they loose speed start going in corkscrew motion wider and wider until they hit the ground.

That means your rifling rate is less than ideal, although whether too steep or too shallow I can't remember.

Impressive nonetheless, although I'd personally be wary of cutting grooves into such thin walls. I have plans to try a different method for 3vo, although I'll be adding lands rather than cutting grooves... and there will be interchangeable barrels for both rifled and smoothbore.

Moving away from my own plans (which I seem to list all too often

)... If you consider that the spuds won't tumble, you could round the nose of a slug and do a decent distance shot - because it would retain a decent ballistic coefficient.

hyldgaard wrote:This post is WORTHLESS without pics of the tool

Very well, if you insist:

Oh come on, he's a total tool.

...Fair enough, I'll get me coat.

Re: Rifled copper barrel

Posted: Sat Aug 16, 2008 3:11 pm

by MaxuS the 2nd

Ragnarok wrote:

hyldgaard wrote:This post is WORTHLESS without pics of the tool

Very well, if you insist:

Oh come on, he's a total tool.

...Fair enough, I'll get me coat.

Actually made me LOL.

Posted: Sat Aug 16, 2008 3:23 pm

by al-xg

I don't usualy shoot spuds, though, my latest canon (I can now call it an air rifle

) shoots 14mm lead balls, diabolo pellets, bullets, (or saboted darts out of the smoothbore) at a much higher speed.

The 1 in 16in turn, is what is often used (or often sugested as a good twist rate) for air rifles and as most of my projectiles will be going at least at 600fps, so it should be ok.

But I could also try other twist rates if that fails.

I didn't use this technique at first as I too wanted less land then grooves in the barrel, but this seems to work fine and I've noticed that along side the grooves are small ridges taller than the barrel ID.

Whats good with french copper tubing, is that you can also get 18mm copper with a 16mm ID so I can always sleeve the barrel if needed.

But I'd trust this copper more than the rifled PVC barrels even though they are thicker...

The useful

tool has been added to the first post.

Re: Rifled copper barrel

Posted: Sat Aug 16, 2008 3:23 pm

by Ragnarok

MaxuS the 2nd wrote:Actually made me LOL.

You know... I think I may have been around AirgunBBS a little teensy bit too much.

There are far too many opinionated old farts with axes to grind there, and I think it may be rubbing off.

Oh well... better stay out of the Off-topic section there for a few days.

Still thought it was an appropriate joke though.

Re: Rifled copper barrel

Posted: Sat Aug 16, 2008 3:37 pm

by MaxuS the 2nd

Ragnarok wrote:You know... I think I may have been around AirgunBBS a little teensy bit too much.

As have I really.

But atleast some of the information we know can be used in the two different hobbies.

Posted: Sat Aug 16, 2008 3:40 pm

by ammosmoke

I'm probably going to get made fun of, but who is that? Blair?

Posted: Sat Aug 16, 2008 3:42 pm

by MaxuS the 2nd

Indeed, you will be made fun of.

That..Is a total moron. He calls himself Gordon Brown, but he's known as many different - derogatory- names.

Posted: Sat Aug 16, 2008 3:47 pm

by Hotwired

I've never been too much of a fan of groove rifling. To use it you need to be firing quite soft ammo which can deform enough to squish into the grooves. otherwise it's just creating channels for gas to blow past.

Raised ridges of the other hand dig in and as long as the ammo is significantly softer than the ridges it'll get a better spin.

It needs a lot more cutting to create ridges unless you manage to secure wire spirals to the inside of a barrel in a way that won't get them shot out too easily.

Interesting work on the tools, how did you get an accurate twist on the heads?

@ Rag: All I can say is that the Pyro has the most awesome taunts in the game. Unfortunately body language and gas mask muffled words don't come through too well in words

Posted: Sat Aug 16, 2008 3:48 pm

by ALIHISGREAT

wow, good job! i may try that myself at somepoint in some 15mm ID copper... oh and did you use a file to shape the tool?

and as for Gordon, has anyone else noticed his wierd jaw movements when he breaths in? its really distracting when he speaks (on TV obviously)

Posted: Sat Aug 16, 2008 4:00 pm

by al-xg

I drew the rifling patern full size on some paper to use as a template to align the dremel in a wrench (held the bolt in the wrench to use the file) and then made sure I kept the bolt straight.

I also cut away each groove a little at a time before turning to the next one, and rectifying it if needed.

This seems to work, with lead, wadding, potatoes and even aluminium, and i can't really think of anything harder that would be expected to follow rifling, even if it is raised edges.

Anything that is a good fit in the barrel seems to get some spin.

Maybe because of friction/no friction...