Page 6 of 7

Posted: Thu Apr 29, 2010 4:17 pm

by spudamine

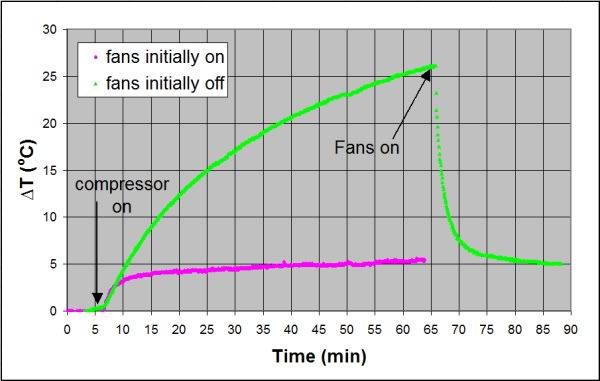

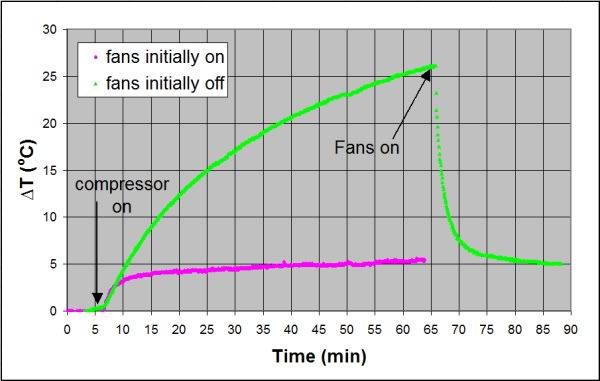

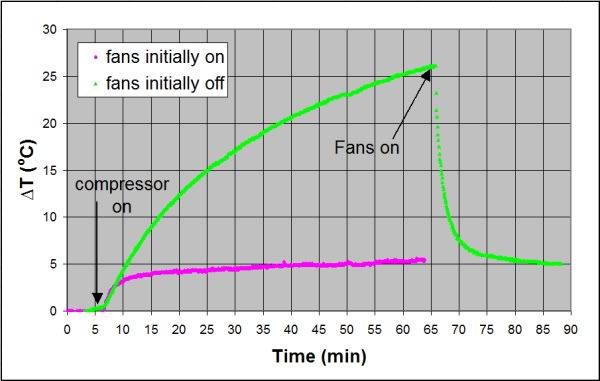

Double post for results. a few people have asked for hard data on using fans to cool compressors, so here it is

just to sum up whats come previously:

Boyntonstu wrote:Blowing air around a smooth compressor housing will provide little or no cooling. (no fins)

rp181 wrote:Agreed. Fans are pointless. Not only do you not have fins, but they put on a nice smooth gloss finish for you. In addition to that, these are potted, epoxy does not conduct heat well at all.

here's my setup, compressor, 2 x 150mm 40W fans, datalogging meter with thermocouple wedged into compressor shell with thermal grease.

Two fans weren't really necessary here but I needed them to drop the voltage.

for the experiment the compressor was operated for 1 hour with and without the fans, furthermore after running without fans the fans were switched on to see how quickly they could cool the runnung compressor. I've pletted delta T, the temperature rise above ambient for clarity:

As you can see with the fans on the compressor hardly heats up even after 1 hour of continuos use. It's a different story without the fans, the temperature rises steadily throughout the experiment, after 1 hour it's 25 degrees centigrade above ambient and still rising. When the fans are turned on the cooling effect is massive and very fast.

I really don't see how anybody reading these results can any longer say that fans are not an effective method of cooling this type of compressor.

Posted: Thu Apr 29, 2010 4:33 pm

by the unit

I like.... the evidence

Posted: Thu Apr 29, 2010 5:06 pm

by POLAND_SPUD

damn... you made me look like a lazzy bastard

Was the outlet free to vent or was it restricted to allow for pressure build up ?

Posted: Thu Apr 29, 2010 7:47 pm

by boyntonstu

spudamine wrote:

I really don't see how anybody reading these results can any longer say that fans are not an effective method of cooling this type of compressor.

A nice experiment to show that a point on the the external shell of a compressor is cooled by a fan.

What is going on inside?

Remember my car analogy?

You have a heater on inside the car SET TO 90* F.

The heater is analogous to the motor and the piston/cylinder in a compressor.

The temperature on the roof is eventually heated to the inside temperature.

Drive down the highway on a 70*F cloudy day with a thermocouple on the roof?

Will the temp at the TC read lower?

Will the interior temperature be cooler?

Next experiment:

Place the thermocouple at the exit of the compressor to measure the temperature of the output before and after running the fan.

Posted: Thu Apr 29, 2010 8:05 pm

by POLAND_SPUD

lol in case you haven't noticed your experiments

A nice experiment to show that a point on the the external shell of a compressor is cooled by a fan.

do not make any sense

it's a completely different situation.. compressor is made of metal and there is oil circulating inside the case so heat is easily transferred to the case

You have a heater on inside the car SET TO 90* F

yeah and the heater is surrounded by air, which is a pretty good insulator

Drive down the highway on a 70*F cloudy day with a thermocouple on the roof?

Do it yourself but first heat the termocouple to 150 deg C and measure whether it cools down faster when the car moves or when it does not

Place the thermocouple at the exit of the compressor to measure the temperature of the output before and after running the fan

that's just air... how come on one occasion you see that there is some heat transfer from air to metal but you claim that air cooling does not work??

analogies are pretty cool but only if they make sense

Posted: Thu Apr 29, 2010 10:04 pm

by c11man

sorry it took so long and i have been wanting to point out that this is wrong

Do you believe your eyes and your ears?

Do you trust real world data more or less than theory?

Watch and listen to this video again.

Link

Do you hear the compressor with pressurized input?

Do you hear the compressor without pressurized input?

If you hear it, is it working easier or harder?

Did the compressor fill the chamber faster or slower with pressurization?

I believe in data more than theory or assumptions.

first of all READ WHAT OTHERS POST! so you dont post inaccurate rants on things no one else even said.

secondly i know for a

fact that a compressor works harder when it has a pressurized input. i have a compressor that uses a pressured input that i have used for way longer than you have.

this is how i tested it: i attached a needle valve to the output and set it so the flow out of the compressor was matched to the flow out the needle valve at 200psi. in other words with a non pressuresed input the pressure inside the fittings on the outlet of the compressor were at a steady 200psi thus making it a accurate test. i let it run in this configureation for 15minutes and i could feel a slight warmth from the compressor case.

before i tested a 40psi input pressure i let it completly cool off (the next day). this time i had it running with the inlet at 40psi and reset the needle valve so that it was at 200psi again( reqired it to be open farther because of greater flow) this time after 15min it was considerably warmer than the previous test. oh and both were with my fan off

now you might say that i couldnt make an accurate comparison of tempature between 2 different days and with only my hand. but the second test was far warmer than the first one

if you are gonna be super anal about it i can redue the test with a infared temp sensor and a watt meter on the power(i might not have the power meter avalible) if that will finaly get you to realize i know what im talking about.

and i do agree that a 40psi input will make your gun fill faster and since it is running for a much shorter time it doesnt get as hot but i works

harder!

Posted: Thu Apr 29, 2010 10:33 pm

by boyntonstu

c11man wrote:

and i do agree that a 40psi input will make your gun fill faster and since it is running for a much shorter time it doesnt get as hot but i works harder!

I have a clamp-on AC ammeter.

To check whether the compressor is working harder with pressurization I will measure the current.

Work = Force x distance and it is measured in Joules or BTU's.

Energy = work x time and it is measured in Joules/hour or BTU's/hour.

Therefore it may be possible that the compressor works harder (draws higher amps) for a shorter times, consumes less energy, and stays cooler as you say.

More amps, more work, and more heat.

Less amps, less work. and less heat.

I will report back.

Posted: Thu Apr 29, 2010 11:12 pm

by c11man

yes the compressor will work harder but for a shorter time resulting in a cooler overall tempature.

i wonder if a 1/4in regulator has enough flow to pressurise the input of my massive fridgy...

Posted: Thu Apr 29, 2010 11:58 pm

by jackssmirkingrevenge

POLAND_SPUD wrote:damn... you made me look like a lazy bastard

Well...

Great job spudamine, now let's see it mounted in a casing

Posted: Fri Apr 30, 2010 12:59 am

by spudamine

damn... you made me look like a lazzy bastard

Was the outlet free to vent or was it restricted to allow for pressure build up ?

the outlet was left open I wanted to run it in for a few hours before making it work too hard, i'm guessing the temp would get even higher with the outlet pressurised, plus it was sending the needle on my gauge crazy.

Great job spudamine, now let's see it mounted in a casing

The next logical thing to do would be to borrow the thermal imaging camera from work, drag it home, and try to further educate boyntonstu about thermal conductivity and heat transfer, but I can't be arsed so as you say I will probably just get on with building the case

Posted: Fri Apr 30, 2010 7:16 am

by c11man

i dont think a case is nessecary, just mount everthing to the compressor like i did

Posted: Fri Apr 30, 2010 7:53 am

by boyntonstu

c11man wrote:yes the compressor will work harder but for a shorter time resulting in a cooler overall tempature.

i wonder if a 1/4in regulator has enough flow to pressurise the input of my massive fridgy...

Perhaps all of this cooling talk is totally superfluous.

The thermocouple experiment measured a 25* C temperature rise after 60 minutes of continuous run time.

If you start out with 25*C and it rises to 50* C, so what?

50* C is coffee/tea drinking temperature, not mechanical burn up temp.

We don't run fridgys for an hour straight.

3-4 minutes run times with no input pressure.

With pressurized input, I fill to 600 psi n 40 seconds.

That is cool in both cases.

Why add a fan?

An interesting question is the design running temperature?

Yes, a 1/4" regulator has enough flow.

Examine the input diameter to a 3,000 psi SCUBA tank or my oxygen tank, it's less than 1/8".

Posted: Fri Apr 30, 2010 8:17 am

by jackssmirkingrevenge

boyntonstu wrote:50* C is coffee/tea drinking temperature, not mechanical burn up temp.

No one is saying that the pump will burst into flames without a fan, but everyone seems to agree that:

- an external fan is effective at keeping the temperature down

- wear and tear is reduced running at lower temperatures

... so why not, if you want to add a fan?

Posted: Fri Apr 30, 2010 8:53 am

by boyntonstu

jackssmirkingrevenge wrote:boyntonstu wrote:50* C is coffee/tea drinking temperature, not mechanical burn up temp.

No one is saying that the pump will burst into flames without a fan, but everyone seems to agree that:

- an external fan is effective at keeping the temperature down

- wear and tear is reduced running at lower temperatures

... so why not, if you want to add a fan?

You can add fans to anything.

Look around your shop; table saw, drill press, etc.

Why not add fans to 'cool' them?

Run your drill press for 20 minutes and see if the motor temperature is cooler than your fridgy.

If it ain't broke, why fix it?

I made a few measurements this morning of my compressor current draw to 350 psi;

Without pressurized input, 4 Amps.

With pressurized input, 6 Amp.

I stand corrected that pressurization reduces the energy into the fridgy.

OTOH The contrast in run time more than makes up for it.

Without pressurization it stumbles at 550 psi and it never sees 600 psi.

With pressurization, it ran past my gauge limit of 600 psi and everything was quiet and smooth.

Posted: Fri Apr 30, 2010 9:32 am

by POLAND_SPUD

Why not add fans to 'cool' them

most electric motors have fans... have you ever seen one ??

if you're so much into experimenting with stuff then hook up your setup to a scuba tank and pump it up to 600 psi.. then check whether it's hot or not

Edited by jrrdw.