Page 1 of 2

My introduction to propane

Posted: Fri May 25, 2012 4:20 pm

by boyce123

I have just discovered this website, and am dissappointed i hadn't found it before. I'm only 16, so excuse my inexperience. This is the second cannon that i have built. The first was a project with my dad when i was 14, so this is the first cannon that i have built by myself.

The goal when i started this build was to make it entirely self contained, but the weight suffered from that (almost weighing 25 lbs), the excessive steel bracketing didn't didn't really help the weight issue. It is currently in fireable condition, but it still requires aesthetic work. It shoots golf balls around 250-300 yards. I plan on making a longer barrel to improve accuracy and range. i havn't made any wooden plugs to determine how damaging it is yet, so thats why i don't have any damage pics yet. And yes, i did and still do recognize the added potential harm of screwing the mounts into the blasting chamber, so i don't need to hear about it (it hasn't blown up after 30 or 40 shots, so i'm assuming i'm fairly safe, as much as potato cannons can be regarded as "safe").

Here are the specs:

-3ft x 4in blasting chamber

-2 in female cleanout for interchangeable barrels

-2 in ball valve for exhaust

-2.5 in computer cooling fan mounted on the outside of the ball valve (i initially had one in the chamber, but it stopped working, so i decided to put the fan where it would be more easily replaced)

-rewired stun gun for ignition

-backup battery system mounted on the handle

-crude/simple, but very effective metering system(without any regulators in an attempt to cut cost and weight); it seems to be at a decent stoichiometry at 65 psi in the 8in x .5in nipple.

-solid steel pistol grip with thumb trigger

-form fit project box to house the electronics

-small piece of 3 in pcv mounted with 1.5 in angle iron to hold the propane bottle, with a small steel clip to hold the tank in.

Things that i need to do to finish it:

-overall body work

-shoulder rest, so it doesnt set on my shoulder with the corner of the project box

-grip for the handle

-battery boxes/covers?

-longer barrel

-paint

HA proof that i'm a bad welder....

General input/suggestions are apreciated

Posted: Fri May 25, 2012 7:02 pm

by D_Hall

In general, nice work. However, as the resident paranoid, the screws and such that you put into your combustion chamber scare the hell out of me. True, it shouldn't be a big deal since your pressures should be pretty low for the setup you've got, it's just not good practice, IMO.

Posted: Fri May 25, 2012 7:25 pm

by Gun Freak

I know the first fan broke in the chamber, but having the fan on the outside isn't doing nearly as much good as if it were inside. Chamber fans make a huge difference in the performance of a 1x combustion. I suppose you could leave the ball valve open and mix it but some propane may be lost. To compensate, you could possibly inject a slightly rich mix into the chamber so that if fuel is lost, it will be closer to optimum mix.

Posted: Fri May 25, 2012 7:27 pm

by boyce123

i knew i would get mass concern with the issues of weakening the chamber, i extensively tested it (while being safely behind a blast shield) to ensure that it wouldn't blow up in my face. it hasn't blown up yet, so i'll trust its integrity and continue my inspections of the chamber to make sure it hasn't cracked.

oh yeah, i forgot to explain my mixing procedure, i leave the ball valve open, as you described, i didn't see a loss in the efficiency, and it seems to have even increased its power due to more oxygen being introduced, i'm thinking of adding a funnel-type end to go between the fan and the outer screen, this would further limit the amount of air that would be able escape out the rear.

Edited by jrrdw, double post. Use the edit button when no one has posted under you.

Posted: Fri May 25, 2012 10:29 pm

by jackssmirkingrevenge

Excellent for a first effort, love the way you integrated the fan guard into it, and the zombie hunter ready bracketing, good stuff!

Posted: Sat May 26, 2012 2:00 am

by natas

Nice cannon, as mentioned before here, only concerne is the bolts going in to the chamber.

Posted: Sat May 26, 2012 11:12 am

by jimmy101

Nicely done.

In the future, if you build another, you can easily reinforce the chamber where you have penetrating bolts. Just take another length of the same size pipe and slice it length wise roughly in half. Drop the piece in boiling water for a few minutes then clamp it around a piece of intact pipe. When it cools the piece will now have an ID equal to the OD of the original pipe. Glue that piece onto the outside of your chamber with PVC glue. Finally, drill your holes through that double layer. This lets you put bolts anywhere safely.

In the photo below there is a triple layer of PVC (pipe, fitting, added layer) where the pressure gauge is mounted. You can see the purple primer mark around the third layer.

In this case a hunk of pipe had it's ID expanded to match the OD of a fitting.

Posted: Sat May 26, 2012 11:44 am

by boyce123

i plan on working on it today, so i'll see if i can get some new pics up, and get a video of it put together.

i ran down to the outskirts of my local golfcourse (off their property of course) and loaded up on ammo, so i plan on having a pretty fun weekend.

@jimmy101, i had never heard of that method to reinforce, it seems as if abs would form fit better under temp.

i was going to get some videos, but it started to rain yesterday, so here are some pics of the damage it did with golf balls from 50ft

i didn't know it was possible to do this.... i thought this was pretty decent damage for a golf ball (only 45 grams), even though it is pretty rotten 1/2 in plywood.

Posted: Sun May 27, 2012 4:04 pm

by DYI

Your launcher is mediocre, if one considers design for performance. The fan should be inside the chamber and left running during the shot to induce turbulence, and the barrel should be longer. The original fan may have been damaged due to lean fuel mixtures, if you actually assumed the internal diameter of the meter pipe to be 0.5" (there is no such pipe available in the nominal sizes solid in the US).

From a safety standpoint, however, your design is nearly as worrisome as your attitude. Most of your parts are not designed for use with pressure, have thin walls, and are made of what appears to be PVC, which is far too brittle to be considered for use in a vessel containing pressurized gas. The latter point is typically excused around here if the former two points are covered, although it should still be avoided where possible.

After building this somewhat poorly suited pressure vessel, you proceeded to severely degrade its safety by putting a

threaded hole through the side of it in a thin section. This feature is a very strong stress concentrator.

Then there's your attitude toward safety which is, quite frankly, appalling. You assume it is safe because it hasn't failed yet. Cracks which may eventually expand far enough to cause failure are not necessarily visible to inspection, and they can propagate every time the chamber is pressurized during firing. Parts can fail after one cycle, or they can fail after

millions. Preventative maintenance and good design with appropriate materials can prevent failure, and you appear to have neither one.

"As much as potato cannons can be regarded as safe"? Have you ever set foot within twenty feet of a propane barbecue? A water heater? An air compressor? Were you crippled by the resulting fear of being blown into small chunks? Pressure vessels can be made as safe as you care to make them. There is no more inherent danger in a potato gun than there is in a pencil. The danger comes from the operator

Posted: Sun May 27, 2012 9:45 pm

by Bowman

DYI wrote:Your launcher is mediocre

I like how everyone doesn't seem to have a problem with it

except you.......

Although I will say, that yes it's mediocre. But it is this guy's first effort. You do have a lot of valid points but maybe tone it down a little lol.....

Posted: Sun May 27, 2012 11:20 pm

by jackssmirkingrevenge

Bowman wrote:I like how everyone doesn't seem to have a problem with it except you.......

I also object, that golf ball should have punched through the plywood like it wasn't even there.

Posted: Mon May 28, 2012 1:09 am

by boyce123

So... DYI, I’ll start off with your safety "concerns", if they could really be considered concerns. your comparison of a pvc vessel to a propane bottle or water heater is nearly comical, beyond the engineering behind the STEEL structures, there are specifically implemented safety measures to ensure safe everyday use (as a pressure relief valve in a water heater). Short of putting a pressure relief valve into a PVC cannon, there is no way to ensure a spontaneous failure will be impossible, unlike the everyday pressure vessels that have been secured for continuous exposure with a guarantee that it won’t fail.

The danger does not come from the operator, beyond the danger of where the operator points the gun, the danger goes to the operator, derived from the engineer telling the operator it’s safe. But as the engineer, i tell you that the PVC is in no way "thin", relatively to higher power cannons, i would accept that the PVC could be regarded as unsubstantial. The Schedule 40 pipe that i used is rated at least at 300 psi, even with the intrusions; the pipe should hold up to the 100-150 psi bursts that are experienced with propane combustion.

The fan that broke did so after a wiring mishap, and as i previously stated, the outer fan seemed to be much more effective (and yes i did test with the fan running the entire time). If the fan would have had generated a significant impact on the gun's performance, i would have found a way to reestablish the internal fan. I had not assumed that the internal diameter of the meter pipe was .5", for at least what i feel about math notation, .5 is more clearly on a computer that 1/2, as the fraction bar is diagonal rather than the more accepted horizontal counterpart.

I’m sorry but try giving me some original feedback, if you actually read my posts you would have seen that i stated multiple times that i had to get a longer barrel. The barrel that i have was just a temporary barrel that i make with a left over piece of pipe. I really don't want to sound like a winey idiot, but i came here for productive and thought through suggestions, rather than the hostility and generally ineffective criticism. So this isn't the Holy Grail site that i once believed it to be, and i hope i don't have some bias toward the people in the site. I haven’t really gotten what i wanted out of the site, so I’m debating whether or not i can further utilize this resource.

Posted: Mon May 28, 2012 1:23 am

by jackssmirkingrevenge

boyce123 wrote:I really don't want to sound like a winey idiot, but i came here for productive and thought through suggestions, rather than the hostility and generally ineffective criticism.

Tact is not DYI's shining attribute but on the other hand, this is the internet and a paper thin skin (or should it be a thin walled chamber

) is not going to get you very far

Posted: Mon May 28, 2012 9:41 am

by DYI

I'll start off with a response to your criticism of my previous post. If you're not interested, there's a section on more "advanced" performance improvements down below.

...your comparison of a pvc vessel to a propane bottle or water heater is nearly comical...

The underlying assumption here seems to be that a spudgun is necessarily a PVC pressure vessel. This is not the case.

...there are specifically implemented safety measures to ensure safe everyday use...

As there should be in spudguns intended for entertainment, as opposed to experimental work.

The danger does not come from the operator, beyond the danger of where the operator points the gun, the danger goes to the operator, derived from the engineer telling the operator it’s safe. But as the engineer, i tell you that the PVC is in no way "thin", relatively to higher power cannons, i would accept that the PVC could be regarded as unsubstantial. The Schedule 40 pipe that i used is rated at least at 300 psi, even with the intrusions; the pipe should hold up to the 100-150 psi bursts that are experienced with propane combustion.

As regards inherent danger, I should have been more clear. I was speaking from the standpoint of the system designer who was also the system operator, as is typically the case with spudguns.

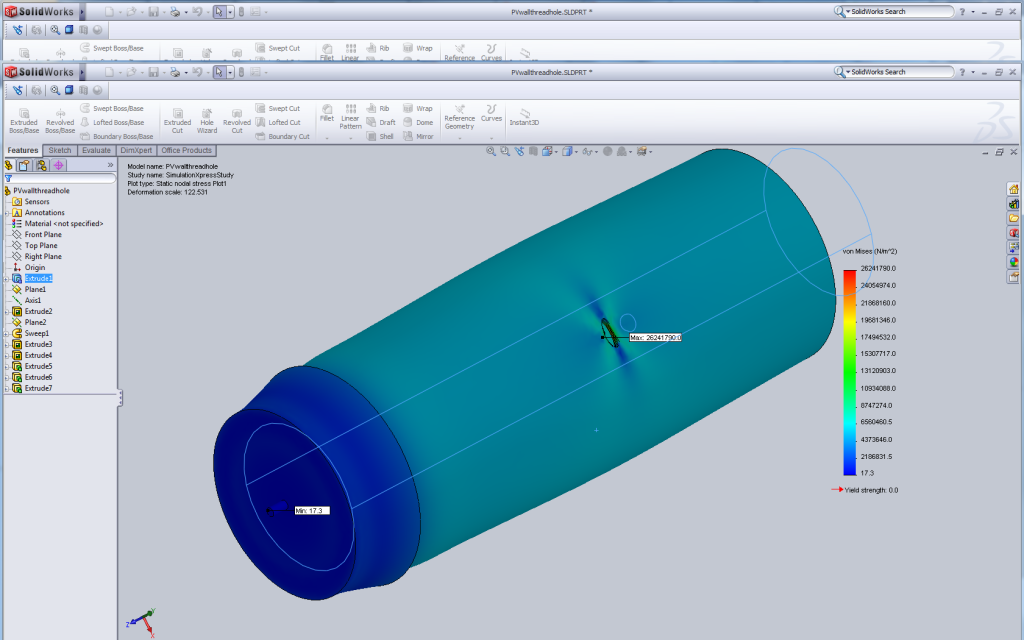

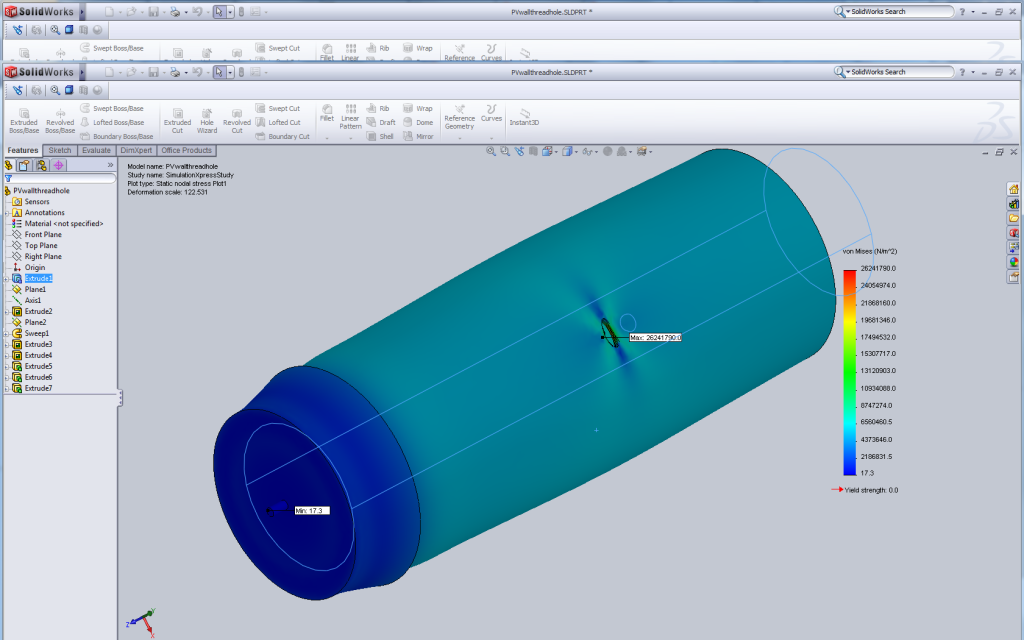

In the case of your assertion that the "intrusions" will not reduce the safety factor of the vessel to an unsafe level, I must inquire as to what FEA software you used to determine this. A quick run through Solidworks' simulation tool (which I acknowledge is far from sophisticated) indicates a stress concentration factor of approximately

FIVE at a 1/2"-20 threaded hole in the wall of a PVC pressure vessel with dimensions similar to yours (the results are shown below, with exaggerated deformation for visual effect). The maximum stress calculated was 25MPa which, while below the yield stress of approximation 40MPa, leaves you with a safety factor of less than 2 at 100psi.

You interpreted my response as hostility, despite your initial implication that spudguns were unsafe in comparison to "engineered" pressure vessels. Just because you don't engineer your pressure vessels does not make that the general case

I'm afraid that the "holy grail" you seek is not as clear cut as you would like it to be. You see, our results regarding combustion guns are all empirical, and they are quite incomplete. There are some suggestions as to further improvement I can offer, but I doubt they will be satisfactory to you. To simulate the combustion spudgun problem properly, one requires at the very least a 2D adaptive mesh CFD simulation with chemical reactions incorporated. This is difficult to write even without the chemistry, and still quite approximate due to the fact that it is still highly empirical - chemistry can be made compatible with continuum mechanics, but it isn't nice, and isn't necessarily accurate. I can give you more to chew on regarding that topic, if you're interested. To understand the problem fully would require something like a 3D CBA model. Running that model on a desktop could take

months.

What we make do with is called HGDT, a 0-D gun simulation with lots of empirical "fudge factors" to push it into line with the existing experimental data (much of it being the Burnt Latke test results). By playing with HGDT, you can attempt to optimize your chamber and barrel sizes, although it can't tell you a whole lot about fan or ignition placement.

For fan and ignition placement, it is worthwhile to consider the case of BigBang's "Crusader" design, which performed unreasonably well. You can view the thread in the archive, although the pictures no longer work. Essentially, a chamber fan near the back of the chamber with a single point ignition placed between the fan and the cap. The design appears to have induced some very favourable flame front instabilities causing rapid combustion and increased pressure generation without actually destroying the PVC launcher. He hit a launcher geometry "sweet spot" so far as anyone was ever able to tell - no measurement error was ever found.

It would also be worthwhile to switch to propylene (MAP-Pro) rather than propane. Its performance is somewhat lower than that of the old MAPP gas (which is no longer available), but it is still an improvement from propane.

If you're interested in shooting potatoes as well as golf balls, a slight bevel on the inside of the barrel (in addition to the outside bevel which functions as a "spud cutter") will improve sealing.

Posted: Mon May 28, 2012 11:56 am

by boyce123

In this case a hunk of pipe had it's ID expanded to match the OD of a fitting.

In this case a hunk of pipe had it's ID expanded to match the OD of a fitting.