Ragnarok wrote:... depends. The average air velocity in the chamber is equal to:Gippeto wrote:The larger volume available at the valve in a co-ax should result in lower air velocities inside the chamber

(Mass flow rate)/(Air density * Chamber cross-sectional area)

If air is flowing through the valve at the same rate, and the air is the same density (i.e same pressure & temperature), then the flow-rate is inversely proportional to the cross-sectional area of the chamber.

For the same chamber diameter, the volume the barrel takes up, will result in a lesser chamber cross-sectional area, and the air velocities in the chamber therefore be greater.

However, there are two caveats on what I've said above.

- Mass flow rate is not usually the same in a coaxial as it is in a barrel sealer. Obviously, the coaxial valve has air flowing into it from all angles, but that air has also got to make a sharper change of direction.

- Coaxials usually have a greater chamber diameter (usually a result of over-compensation for the barrel's volume), which means that the chamber cross-sectional area is usually higher.

... yes, but the change might well be insignificant.boyntonstu wrote:Take any coax and pull out the barrel to use as the chamber. You automatically have a more powerful gun.

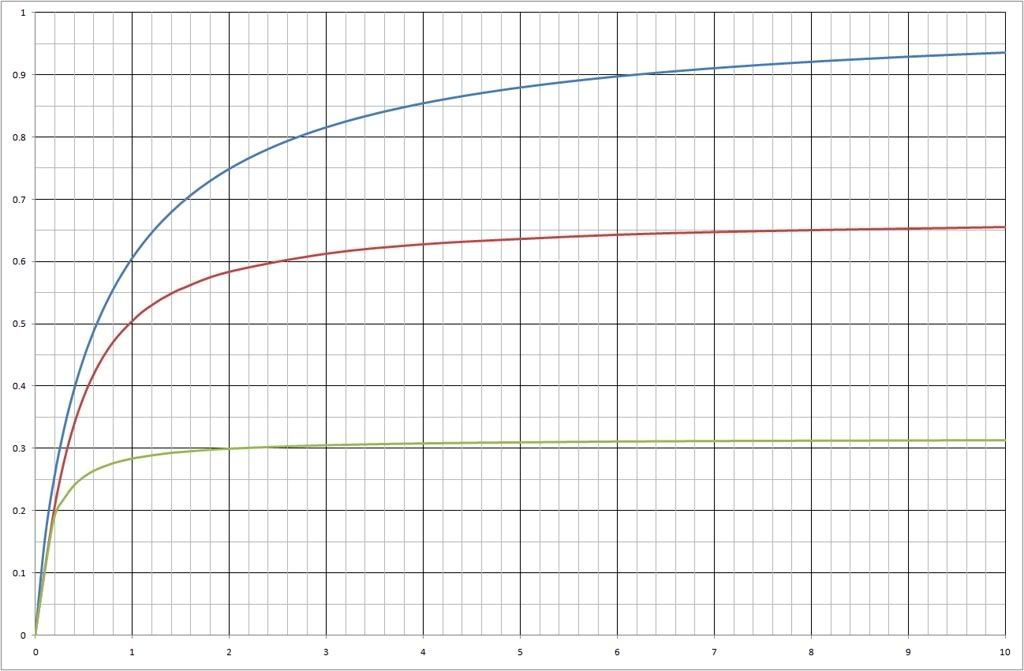

I've talked about C:B ratios before. Here's a nice graph:

On this graph, the X-axis is C:B ratio. The Y-axis is the percentage of the theoretical maximum energy possible from an infinite C:B ratio with no velocity or valve losses.

What you're looking at here is figures for HEAL firing a 20 gram projectile.

The blue line is the theoretical energy that can be achieved from a given C:B ratio, with no velocity or valve losses.

The red line is the energy if velocity and valve losses are taken into account - courtesy of Apocalypse simulations.

The green line is the energy if losses are taken into account - but simulated with a halved valve diameter (no other changes).

You can see that the muzzle energy tends to a limit, with definite diminishing returns.

HEAL's normal C:B ratio is roughly 1.5:1, from which it gets about 80% of the muzzle velocity that an infinite C:B ratio would offer. That is, no matter how much larger I make the chamber, it cannot manage more than 25% more muzzle energy.

On a more practical (i.e. finite) scale, doubling the chamber to 3:1 would increase muzzle energy by less than 10%.

~~~~~

Now... something you probably don't want me to say.

Take into account the whole difference that arises from changing the valve diameter.

The fact that coaxials almost invariably have a full diameter valve means that any flow restriction at the valve is pretty small. The Trom-Boyn on the other hand, does not have a full diameter valve, and that means it suffers for it.

The next point is that coaxials usually have a high ratio of chamber cross-sectional area to barrel cross-sectional area. 3:1 or more is not unusual, so that means that velocity losses in the chamber are minimised. And back to the Trom-Boyn, which has the same diameter for both barrel and chamber - and again, it'll suffer for it.

You're here to talk about how the Trom-Boyn betters a coaxial cannon when the Trom-Boyn is actually limiting the performance that it could get out of its barrel. A co-axial does not limit the performance it can get out of its barrel. It might limit the performance it can get out of its chamber, but that's usually insignificant compared to limiting the barrel.

For the same barrel and pressure* as the Trom-Boyn, I'd back a co-axial over it for fps and fpe!

*Of course, the trouble with 600 psi in high diameter tubing exists, but it's not impossible to find pipe that could handle that. Some decent steel tube or some nice aluminium would take that quite easily.

However, if you were talking about a more optimised barrel-sealing cannon (HEAL being a possible example), without such limitations at the valve,, then you've got something that a co-axial would have to work at keeping up with, but the Trom-Boyn is not thus blessed.

Don't know how you've managed to get an area of 1.43 sq. in. for a 2.5" barrel. That'd be a 1.35" barrel.The areas are 1.43 and 0.785 square inches.

The number you want is 4.9 sq. in.

Thanks for correcting my math error. Appreciate that.

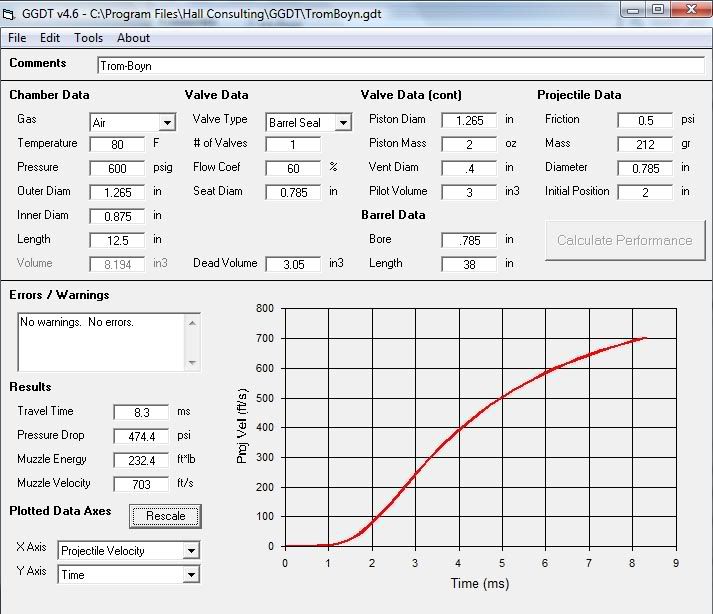

GGDT accurately predicts the chrono performance of the Trom-Boyn with the following :

Design a coax with GGDT and let's compare.