I'm quitting attempting to make piston valves.

I thought this time I would get it right, and I knew exactly what to do. I even made the piston out of pvc using a lathe at my school, what a waste of time. I'm entirely discouraged and frustrated. The chamber charges and the barrel seals fine, its just that when I go to actuate the valve all the air escapes out of my blowgun. Is that little slot at the back of my piston (the equalization hole) too big? any help appreciated.

It probably wouldn't hurt to reduce the hole. It could be done by extending the barrel just a smidgeon more in the tee.

Also, how smooth does your piston slide? It may be that air is getting into the pilot area by somewhere else than that equalization slot.

Dude, don't give up on a good thing. Once it is done right, you will be proud.

Also, how smooth does your piston slide? It may be that air is getting into the pilot area by somewhere else than that equalization slot.

Dude, don't give up on a good thing. Once it is done right, you will be proud.

Advising against dremeling the tee. Now that you have the layout (which is a very clean one) get a new tee and bushing. Just don't dremel the tee, then reuse it. It may damage the tee (even if you can't tell) making it useless for pneumatic use. Play it safe and replace the tee.

hey dont quit im sucking making my first piston valve and i dont think its gonna work so i just wasted 100 bucks on this cannon. Im still gonna see if it works but i did change my sealant to a inner tube and it got somewhat better but it isnt sealing and air is leaking throught it. I am gonna keep trying until i make a succesful piston or a new cannon with a piston. Good luck with your piston.

Did you see the thread I posted earlier? I haven't tried this but it is promising. It may solve your sealing problem.LikimysCrotchus5 wrote:hey dont quit im sucking making my first piston valve and i dont think its gonna work so i just wasted 100 bucks on this cannon. Im still gonna see if it works but i did change my sealant to a inner tube and it got somewhat better but it isnt sealing and air is leaking throught it. I am gonna keep trying until i make a succesful piston or a new cannon with a piston. Good luck with your piston.

Hi,

Noooo, don´t quit. You do nice and clean work, and you use the right parts. You have no sealing problems either. That is a long way towards a working valve, and a nice one too.

But there is a flaw somewhere. I think everybody here will be happy helping you solve it out.

I want to suggest you an experiment: Instead of triggering it with a blowgun, try with a ball valve. For a first experiment, if you don´t have a ball valve, try charging the chamber to just 20-30 psi, and just unscrew one of your brass fittings on the trigger line. Does it fire then?

If it does, then the problem is that you blowgun can´t clear the air that goes between the tee and the piston fast enough. Verify the guess by wrapping the piston in conduct tape to make the seal a little better. Can the blowgun fire it now?

An ultimate solution could be the ball valve, or a pilot valve between the blowgun and the piston valve (that a lot of us, including me) also use, and/or an o-ring on the piston.

Regards

Soren

Noooo, don´t quit. You do nice and clean work, and you use the right parts. You have no sealing problems either. That is a long way towards a working valve, and a nice one too.

But there is a flaw somewhere. I think everybody here will be happy helping you solve it out.

I want to suggest you an experiment: Instead of triggering it with a blowgun, try with a ball valve. For a first experiment, if you don´t have a ball valve, try charging the chamber to just 20-30 psi, and just unscrew one of your brass fittings on the trigger line. Does it fire then?

If it does, then the problem is that you blowgun can´t clear the air that goes between the tee and the piston fast enough. Verify the guess by wrapping the piston in conduct tape to make the seal a little better. Can the blowgun fire it now?

An ultimate solution could be the ball valve, or a pilot valve between the blowgun and the piston valve (that a lot of us, including me) also use, and/or an o-ring on the piston.

Regards

Soren

- jrrdw

- Moderator

- Posts: 6569

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

- Contact:

What he said! Unscrew the blow gun.dongfang wrote:Hi,

Noooo, don´t quit. You do nice and clean work, and you use the right parts. You have no sealing problems either. That is a long way towards a working valve, and a nice one too.

But there is a flaw somewhere. I think everybody here will be happy helping you solve it out.

I want to suggest you an experiment: Instead of triggering it with a blowgun, try with a ball valve. For a first experiment, if you don´t have a ball valve, try charging the chamber to just 20-30 psi, and just unscrew one of your brass fittings on the trigger line. Does it fire then?

If it does, then the problem is that you blowgun can´t clear the air that goes between the tee and the piston fast enough. Verify the guess by wrapping the piston in conduct tape to make the seal a little better. Can the blowgun fire it now?

An ultimate solution could be the ball valve, or a pilot valve between the blowgun and the piston valve (that a lot of us, including me) also use, and/or an o-ring on the piston.

Regards

Soren

-

Novacastrian

- Staff Sergeant 2

- Posts: 1603

- Joined: Sat Aug 11, 2007 6:59 pm

- Been thanked: 1 time

I think the hole in the piston could be to blame.

However i have never completed a piston gun, so take that with a grain of salt

However i have never completed a piston gun, so take that with a grain of salt

I cant see the barrel properly, but what it might be is there isn't enough force pushing the piston back.

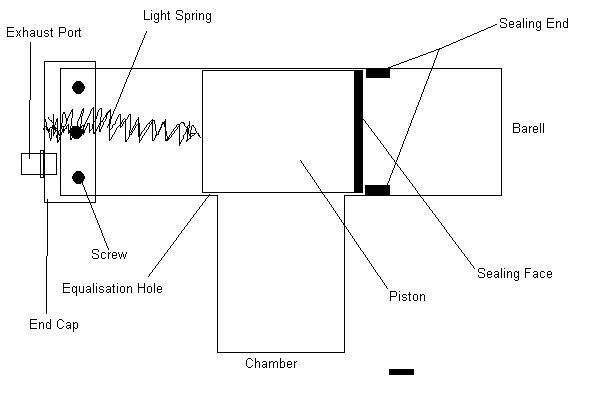

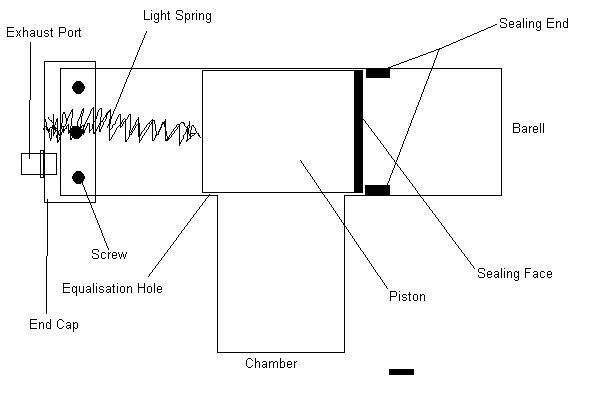

For example, here is a piston valve i made in paint .

.

It wont work because there will be no air pushing against the piston to make it move back.

It could also be the hole behind the piston in combination with the spring, this might make it easier for the air to escape through the exhaust valve instead of pushing the piston back and releasing air through the barrel.

These may or may not be the reason, I'm just saying what i would do to debug the valve if it was me.

For example, here is a piston valve i made in paint

.

. It wont work because there will be no air pushing against the piston to make it move back.

It could also be the hole behind the piston in combination with the spring, this might make it easier for the air to escape through the exhaust valve instead of pushing the piston back and releasing air through the barrel.

These may or may not be the reason, I'm just saying what i would do to debug the valve if it was me.

Failure to plan is planning to fail.

The 7 P's - Proper Prior Preparation Prevents Piss Poor Performance

The 7 P's - Proper Prior Preparation Prevents Piss Poor Performance

i had a problem like that on my first piston, try these suggestins(pretty much what everybody else said just in a list)

1. try wrapping yor piston with electrical tape if it moves to loosly or wobbles around

2. make sure your barrel is about half way through the tee

3. get a bigger pilot valve.

4. you did a great job on valve, becoming a good spudder is about expirence and passion for your creation, somthings just take a little trial and error before they work the way you want it to.

5. for us to help you more it might pe useful to see more pictuers of the inside of your tee with and without the piston in it and your pilot valve a couple pictures at diffrent angles could help us understand the problem better.

1. try wrapping yor piston with electrical tape if it moves to loosly or wobbles around

2. make sure your barrel is about half way through the tee

3. get a bigger pilot valve.

4. you did a great job on valve, becoming a good spudder is about expirence and passion for your creation, somthings just take a little trial and error before they work the way you want it to.

5. for us to help you more it might pe useful to see more pictuers of the inside of your tee with and without the piston in it and your pilot valve a couple pictures at diffrent angles could help us understand the problem better.

- turbohacker

- Specialist 3

- Posts: 392

- Joined: Wed Dec 20, 2006 12:34 am

Your only problom is that the piston is to long.

I guarentee that if you shorten the piston by about a half inch and extend the barrel that far as well, you will have results.

I guarentee that if you shorten the piston by about a half inch and extend the barrel that far as well, you will have results.

Last edited by turbohacker on Sat Sep 22, 2007 9:19 pm, edited 1 time in total.

<-- This is not a cat avatar

If it walks like a dog, sratches like a dog, and barks like a dog, than its probobly a...-TURTLE, it's a TURTLE!!! Cant you see?!!!

If it walks like a dog, sratches like a dog, and barks like a dog, than its probobly a...-TURTLE, it's a TURTLE!!! Cant you see?!!!

frankrede wrote:Great googlay mooglay!

Thats a beast!