Page 1 of 2

A Revolver Question or Solution?

Posted: Tue Nov 13, 2007 5:26 am

by Hubb

A while back, I posted a question about a pump action or semi-auto. With all the feedback, I decided to construct a pump-action revolver.

One of the problems I faced with this is the rotation and sealing of the cylinder. In a revolver, about the only solution I found through searching was have the cylinder rub against the breech of the gun. This presented a problem in itself. To get this to work, one would have to carefully machine the cylinder and the action to line up exactly.

What I came up with (which was asked in the above mentioned thread but went unanswered), was the pic below. The cylinder is comprised of individual shells. When the cylinder rotates, the shell in the receiver pushed both of the flared pipes open. As the shell moves out of place, a fresh shell moves in place. When the shell is aligned, the springs push the flared pipes over the shell.

I figured this would allow for perfect alignment every time, while allowing one to not have to be exact on the machining process. Any thoughts, comments, complaints?

Before anything is said, I know that the springs are going to have to be just right.

Edit: Just had another thought; Would this not work for a conventional breech load also?

Posted: Tue Nov 13, 2007 5:40 am

by jackssmirkingrevenge

might take a bit of effort to rotate the cylinder if it's being held by the flared pipes.

Posted: Tue Nov 13, 2007 5:43 am

by Hubb

Well, that would be worked out using all that physics stuff I learned about a while ago. It's going to be a pump action. It will take a little effort but I think I would rather deal with this problem than deal with the whole "getting everything exactly right without having the right tools" problem.

Posted: Tue Nov 13, 2007 7:17 am

by jrrdw

Bell cranks on the flared fittings. Hook them to the control rods that are worked by the pump. Problem with this theory: Leaky fittings. Being that they slide on a pressurized pipe??? Solution: Flare the inside of the sliding fitting and the outside of the pressurized pipe they slide on.

The shell is not going to be pressurized is it?

Or, this is going to be piston valved, and the above mentioned will only have pressure when fired?

Posted: Tue Nov 13, 2007 10:12 am

by EGOed

I have been toying around with an idea I came up with for a multiple grenade launcher with a rotating cylindar similar to what you want to design ....I had an idea after I saw some pumps at work that operate with magnetic seals and run at 200psi discharge pressure..The magnets are the only force sealing this pressure an was wondering if magnets could be used to align a chamber & cylindar with a barrell ...You can buy rare earth magnets in different sizes and strength ....It would be possible to mold the magnets into an epoxy to possibly create a seal and solve the alignment problem ....Would love to try it when I get some time.

Posted: Tue Nov 13, 2007 5:51 pm

by Hubb

@jrrdw: I plan on making a piston (or diaphragm) valve, but it is going to be sitting behind the above setup. It will have a "fixed barrel" coming from the valve, then into a piece of pipe (the piece of pipe os the larger one in the diagram). Does that make sense?

@EGOed: I never thought of using rare earth magnets. That is a thought I am going to have to consider. It seems that it will be easier as well. Thanks.

Posted: Tue Nov 13, 2007 8:50 pm

by jrrdw

hubb017 wrote:@jrrdw: I plan on making a piston (or diaphragm) valve, but it is going to be sitting behind the above setup. It will have a "fixed barrel" coming from the valve, then into a piece of pipe (the piece of pipe os the larger one in the diagram). Does that make sense?

@EGOed: I never thought of using rare earth magnets. That is a thought I am going to have to consider. It seems that it will be easier as well. Thanks.

Yea, i understand what your saying, still have to figure out a way to seal the cylinder/s before you shoot.

Posted: Sat Feb 16, 2008 8:30 pm

by PinHead

Hubb, have you come any farther on your design for this? I've been following a few of your posts and it seems like you have some great ideas. I have considered making a pump action revolver as well, partly because if it's successful, you could add an air powered piston to actuate it and theoretically make it into a semi-auto.

I don't think it would be as hard as you think to get your revolving cylinders to line up perfectly with your action/barrel. Really, all you would need is a good miter saw with a square/protractor to ensure that you have a perfect 90 degree cut, and some kind of stop to ensure that every piece is the exact same length. After you have them all cut and arranged into a revolving assembly, you can make a sanding block from a large, flat board, big enough to cover all of the revolving chambers at once, and surface them until they are all parallel. If you go all the way up to 1000 grit or so, you will end up with a smooth, unbelievably slick mating surface.

If you do this all right, you shouldn't have to worry too much about sealing issues. You can take this a step further by cutting a groove into the face of your barrel rubbing against the cylinders, and glue a large o-ring into place. Keep these o-rings lubed up well and you should be set.

Like I said, I only have these things in mind because I've been contemplating some of the same ideas as you. I'd be really interested in your ideas on how to rotate the cylinders with a pump action; I thought up a really good simple one just the other day that I wouldn't mind sharing. Heck, I'd be delighted to see someone build it so long as I got some credit for the idea.

On another note, I also saw you were asking about PVC pipe that fit snug over 1.5" tubing; you wouldn't be planning on using that as your slide for the pump, would you?

Posted: Mon Feb 18, 2008 4:32 pm

by Hubb

As far as building, I haven't started. I got sidetracked on the hybrid and lack of money (the hybrid costs a total of about $15).

I have, however, been working on, still on the blueprints for this idea. As far as catching the cylinder as it rotates, I think I will go with something like

this idea, just modified.

Making the cylinder rotate, I thought of having a elbow piston. As I stroke the pump back, the piston moves up, which causes it to work like a traditional revolver. I'm still sort of stuck on this and would love to see your idea about it.

Like I said, the thought is still there, it's just been delayed. Maybe I can get it working by the summer time.

As far as the valve, I was thinking of taking

this idea from Dr Nerf and making it work for me. I feel that would give me a semi-auto type of shot, which will allow the next fill to be ready when the round is chambered.

Posted: Mon Feb 18, 2008 10:21 pm

by PinHead

I think the piston sounds like an decent concept, if you give it some more thought. I had considered a similar idea at first, just using a rod on a pivot instead of a piston, but it didn't translate really well to a pump action. The piston would be better; I assume that you'd be using a flexible cable inside the elbow to push on the piston?

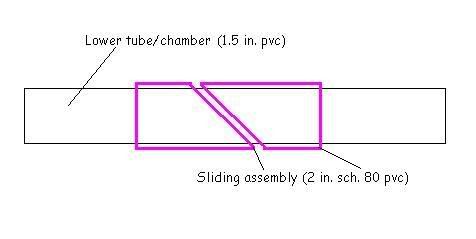

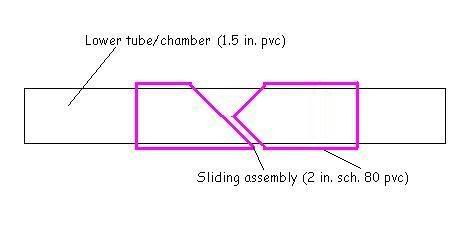

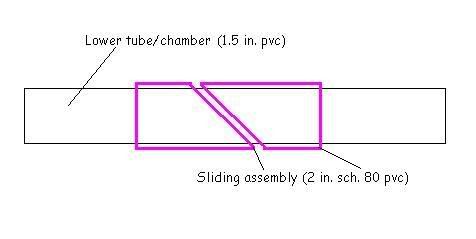

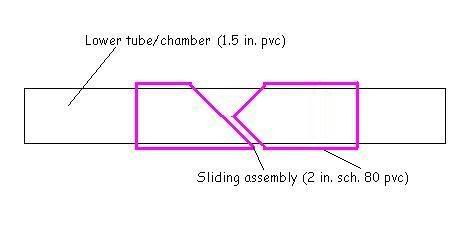

My second idea was a bit better, but I have a hard time explaining it. First off, the cylinders would be constructed as a six-shooter, with the six chambers wrapping directly around the bottom tube of an over-under, with the bottom tube being your pressure chamber. Basically alot like Solar's Eclipse launcher. Now over the bottom tube, right in front of the revolving assembly, we have another piece of pipe slid over it - probably 2" OD schedule 80, which is supposed to be a good fit. Obviously this piece would have a slit cut down the middle, since it couldn't wrap all the way around without getting in the way of the barrel. The barrel has to be directly on top of the chamber, or else the revolving cylinders won't line up.

Now let's take that slide over the bottom chamber, and let's cut it in half, at no less than a 45 degree angle. It'll look something like this.

Now, say we take the front half of the slide, and we rotate it, say, 90 degrees. Now it looks more like this.

Notice that not only has our front slide rotated, but it's also moved forward a couple inches, since they don't line up perfectly anymore. But the theory is this -

If we move the front slide back and forth, then the back slide will have to rotate in order to line up correctly, if the front slide is pushing up against it. The rotating slide will be used to turn our cylinders, and will need a spring on the side to pull it back into home position, after the front slide is pushed back forward.

I hope that I didn't just make that waaay too complicated, but hopefully you get the idea. Let me know if I can clarify anything more.

Posted: Mon Feb 18, 2008 10:53 pm

by Hubb

That was what I considered at first. I actually disassembled a Nerf Maverick and it was set up similar.

As far as my "round setting piston" I thought of using a flexible cable, but also thought about using an actual piston with plungers and allow the air pressure to push the chamber.

As far as the launcher setup, Solar did inspire me and I was going to have the cylinder rotate around the chamber in an over - under configuration.

My goal is to make it work great, but be simple at the same time. The simple part is what keeps stalling my blueprints.

The attachment may help to better explain the piston cycle idea:

Posted: Mon Feb 18, 2008 11:23 pm

by PinHead

I think that looks fine, but you're right about the simplicity being so important. Half of the ideas I've come up with so far were ditched for that reason. It's kind of cool that we both have so many ideas in common, including the main goal.

I toyed with an idea using a 90 degree elbow but I never thought about simply using air to push the piston. That would eliminate the need for any kind of cable or linkage; the only thing you'd have to worry about is leaks, but they shouldn't be too hard to fight.

Did you consider using pressure from the chamber to power your piston? If your chamber was emptied and refilled after every shot, you'd have a semi auto, right there - and it would actually be more simple than a pump, since you'd only need the single piston by the cylinders. Of course you'd lose the obvious 'cool factor' that comes with a pump. There really aren't too many, if any, pump-action designs on this board.

Posted: Tue Feb 19, 2008 12:53 am

by Solar

Earlier models of my Eclipse Launcher used a linear rack and ratchet system. Refilling of the piston by the main chamber happened to quickly to insure reliable operation even with a quick exhaust port. To change the direction of action is a bit of a space hog, even with a 6" cylinder. In regards to indexing accurately, look at spring plungers on the mcmaster-carr site. Dimpling the back of the spindle will allow even a rough index to be placed properly by the plunger. These experiences led me to the current cam driven indexer. Best choice... air extend piston, spring back to revolve.

Posted: Tue Feb 19, 2008 2:43 am

by Hubb

I did consider having the cylinder operated by the main chamber. But, in my second sketch, there are actually two chambers, the main chamber and secondary chamber. A regulator will fill both chambers from a constant air source. Once the trigger is pulled, the main chamber is cut off and the second chamber (which is smaller) will release through the barrel. When the trigger is released, the barrel is blocked and air from the main chamber refills the secondary chamber. The regulator then puts the remaining air into the main chamber.

This method should allow for almost instant follow up shots and will conserve air from the source as the main chamber will only need approximately 5 psi to refill to its max from the reg.

I may can incorporate that into the piston recock idea, but, like you said, I would loose the "cool factor" of having he pump, which was actually something I wanted to keep (I even designed a little noise maker to go with it to make the racking sound).

@Solar: I'm not quite sure I follow what you're saying. I think I understand a little, but it may require a little more explanation for me to fully grasp it.

Posted: Tue Feb 19, 2008 5:11 am

by Solar

I will dig up my spare parts box out of storage tomorrow and find the assembly for you. Basically I used a hexagon with horizontal pins that were driven by a clippard piston attached to a pawl. The hexagon would ratchet to roughly the next position and a flat piece of delrin being pushed down with two springs would align to the top of the hexagon to align the cykinders. I will post some pics if I can find them.