Page 1 of 1

2400 psi piston valve, final design

Posted: Sat Dec 15, 2007 12:13 pm

by DYI

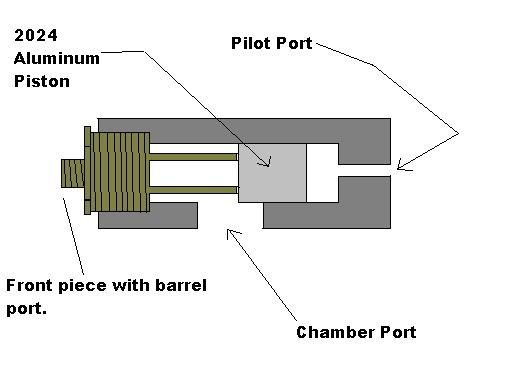

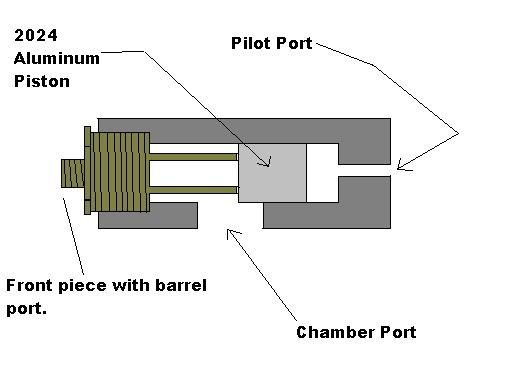

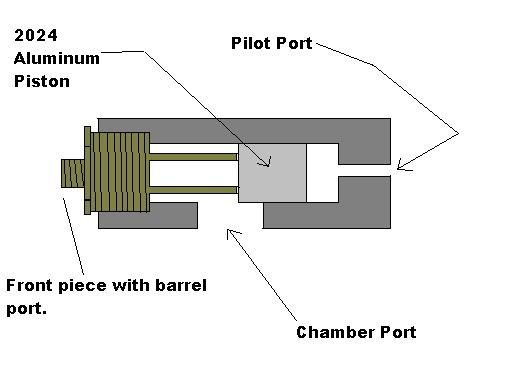

I've finished designing the piston valve for the mini version of my upcoming ball bearing gun. It looks something like this

but with a few changes.

Namely: the piston has been changed. It will now be built in two pieces, which will be cut to length (1" each), epoxied together, and bolted, after which the piston will be machined down to the correct diameter (.749").

The front half (the part that seals on the barrel) will be PTFE, while the back half will be high impact resistance polycarbonate.

The front part of the valve, that threads in with straight threads for easy access will seal against a flat face with a butyl rubber gasket, as well as the threads being sealed with teflon tape.

I have already done extensive research, and have ordered the parts from McMaster already (being shipped from the states by a friend).

If anyone can see an obvious problem in the design, now is the time to point it out.

Posted: Sat Dec 15, 2007 12:18 pm

by jackssmirkingrevenge

Make sure you have your bumper sorted out, otherwise over time the ali piston will crush and expand in diameter, potentially jamming in the chamber.

edit: ah, you changed the piston materials, but still, make sure your bumper's sorted to avoid potential shatter.

What calibre is this going to be? At commercial PCP pressures using a much more efficient valve, the performance should be quite impressive - i fear for your shed

Posted: Sat Dec 15, 2007 12:50 pm

by DYI

What would you recommend for a bumper Jack? The polycarbonate was intended to act as the bumper, but it might get crushed over time. Do you think the teflon will seal, assuming an extremely flat sealing face?

As for power: This is a small scale version of the bigger valve I was planning. The porting will be 5/16" (.3125), the barrel will be 6' x .257", the chamber will be 5ci, the gas will be helium

, and the projectiles will be .25" tungsten carbide or tool steel ball bearings.

Posted: Sat Dec 15, 2007 12:58 pm

by jackssmirkingrevenge

With the sort of pressure that will be on it, the teflon should seal well, prodivded of course that the sealing face is indeed perfectly flat. As a bumper, a few mm thickness of rubber should suffice, just as long as the piston doesn't impact directly on a hard surface.

What are you going to use as a pilot? A ball valve seems the most logical option, though not very ergonomical - then again, I have a feeling this will be more of a "test" launcher permanaently strapped to a surface as opposed to a portable weapon, particularly with such a long barrel.

With that sort of projectile and helium as a propellant, performance should be well in excess of a 22LR rifle, looking forward to seeing this built

Posted: Sat Dec 15, 2007 1:07 pm

by DYI

Performance with the carbide bearings will be about 3x that of a .22 LR.

The pilot valve will be a gem I discovered on McMaster today: 3/8" porting pressure washer trigger valve, rated for 4kpsi. Provides a perfect grip as well as a 4 finger hair trigger that won't move the whole device on firing.

The first few feet of the barrel will be encased in a sleeve made from epoxy with copper tube on the outside, and will be propped on a bipod to fire. And the whole thing will be a portable design.

The rubber shouldn't be too hard to get a hold of; simply cut up a tire or something.

Posted: Sat Jan 05, 2008 10:11 am

by SPG

OH, I think you've gone and bought the bits now and I'd not seen this before, but for a piston bumper you might (have) consider(ed) an elastomer from MTB suspension. Some of them use elastomer stacks as their supsension and shock absorbtion, and you can buy different stiffness elastomers to tune the suspension. Not too expensive and very good at reducing the shock forces of your piston I should think.

Posted: Sat Jan 05, 2008 11:11 am

by mark.f

I've used tennis-ball cutouts for nearly all my pistons bumpers. They're cheap, and the thick rubber works for nearly all diameters. In smaller diameter pistons, simply a small circle cut-out absorbs shock fairly well, and in larger valves, (think 2" tee based), a conical cut-out with another cutout in the center for air to flow "squishes" upon impact and absorbs shock well too.

Maybe you should reconsider your shooting range is it's going to have 3x the ft/poundage of a .22LR. Either that or order a truckload of red-clay or gravel to dump into a small hill to shoot against. I don't think your parents would be too crazy about several cubic yards of clay dumped into your backyard, though.

Posted: Sat Jan 05, 2008 5:56 pm

by DYI

Backstops and ranges will be a consideration after I actually get the valve built and working. One step at a time here.