Page 1 of 1

Leaky piston housing

Posted: Sun May 25, 2008 6:36 am

by Biopyro

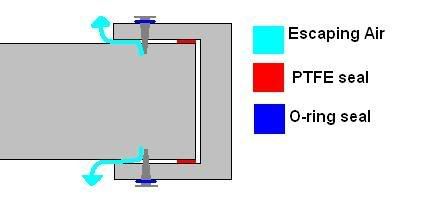

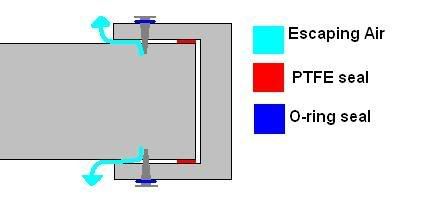

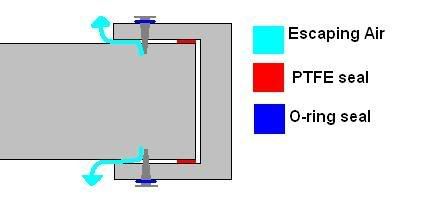

I am nearly finished my new piston cannon, but I'm plagued by leaks. The most severe one is where the endcap connects to the rear of the piston.

I have sealed the endcap itself with ptfe so what I think is happening is that air from the screw holes is escaping between the endcap and the pipe.

My question is, what's the best way to stop this? I tried putting PTFE on the screws but it just gets pushed up as it's screwed in (yes, I'm putting it on in the right direction), and I don't really want to use epoxy of filler, since I want it to be serviceable

Posted: Sun May 25, 2008 6:52 am

by jrrdw

O-ring inbetween the end cap and pipe should do the trick. Mid way, not at the very end.

Posted: Sun May 25, 2008 7:08 am

by Biopyro

I can't fit one in because it's too tight, and I don't have access to a lathe. I was thinking of finding a filler which dissolved in something (not water) which PVC doesn't, so when I do need to service it, I can just dissolve the filler without damaging the PVC.

Posted: Sun May 25, 2008 7:40 am

by brogdenlaxmiddie

Hot glue might work, it seals pretty well, but your prolly strong enough to break the bond when you need to service it...

edit- Who likes my new avatar?

Posted: Sun May 25, 2008 7:55 am

by Biopyro

Good idea, what temperature does hot glue soften at? Maybe I could melt it off.

Erm avatar is a little...

odd, distracting

Edit: I have put some filler called "Gripfill" in the gap, which is less than 1mm. Can anyone recommend something reliable for filling gaps in spudding? The pilot valve X pilot volume connection is pretty leaky too, however Gripfill has already made an improvement there.

Posted: Sun May 25, 2008 2:10 pm

by MrCrowley

I had the same problems. I just gave up and glued the damn thing on. Haven't had a problem since, and the piston is still going strong.

You can always lube through the barrel port as wel

Posted: Sun May 25, 2008 2:25 pm

by STHORNE

brogdenlaxmiddie wrote:Who likes my new avatar?

It is pornographic and obnoxious! Not to mention petifile-ish!

You should be banned for posting obscene images of a naked child dancing!!!

lol, jk...

It's ok (if you have the mind/humor of a 8 year-old)

And about the screw-sealing issue, EPOXY! lol

Epoxy is extremely strong and has a really good pressure rating when cured.

You can buy the "Quick Tite 5-minute" Epoxy at Walmart for $5.00, but judging on the pvc in the picture, I'm guessing you don't live anywhere near a Walmart...

Posted: Sun May 25, 2008 2:51 pm

by Biopyro

About 6000km from the nearest wal-mart, in sunny England. For some reason using epoxy did not occur to me :S

All my PVC parts come from hendersons plastics, without doubt the best UK retailer, and they stock almost every fitting upwards from 1/2" threads to 160mm.

I had been thinking of just gluing the cap on when the piston is troubleshot, however the 4 holes might be difficult to align when gluing so fingers crossed this works.

And brogdenlaxmiddie: I didnt wanna seem to harsh but on further reflection, I don't like the avatar. Aside from creepy it really is just immature.

Posted: Sun May 25, 2008 8:25 pm

by jrrdw

You can make a o-ring groove with a medium round file, it happens quicker then you think.

Posted: Mon May 26, 2008 3:34 am

by Biopyro

I may do that then, but what worries me is I will need a 63mm o-ring, which is less than 3mm thick because of the wall thickness of the pipe.

I'll have a look if the gripfill doesn't seal it.

Edit: the gripfill means I can now take it to 3.5bar, but obvioulsy this still isn't good enough. I bought some epoxy and it should arrive by Wednesday, I'll use this to seal the valve, then after that trim the pilot volume and glue on the cap

Posted: Mon May 26, 2008 6:06 am

by dongfang

Hi,

I have used silicone successfully several times. It has almost no mechanical strength (but I suppose your bolts do that part - sorry I'm on business class here and there's a firewall against photobucket) but it will seal OK. Just apply some to the fitting and some to the cap, and push it on.

When you need to get it off again, remove the bolts, place a big soft something behind the end cap, and pressurize. It will pop off at 2-4 bar or so.

Regards

Soren

Posted: Tue May 27, 2008 3:48 am

by Pyro Ninja

I say piss the end cap off

and use a good old female connecter and a plug.

Posted: Fri May 30, 2008 3:18 am

by Biopyro

Well the silicone did nothing, the air just pushed past and leaks as normal. Now the sealing face is leaking more than ever

It's 2 pieces of tyre inner tube, roughly 3mm together. The washers are very tight where the screw is so I'm pretty sure it isn't leakingfrom there, asnd it still leaks at >40psi. Do i just need a thicker sealing face?

Edit: I am shocked by my own poor craftsmanship! It turns out that the leaking "sealing face" is in fact poor solvent welding of the little bit of 40mm which the sealing face seals on. It's hard to explain here, but a little epoxy should do the trick. The thing is, I don't recall this joint leaking at this badly before although I did think the sealing face was leaking a little.