Page 1 of 2

different blow forward design

Posted: Sun Aug 03, 2008 5:17 pm

by trollhameran

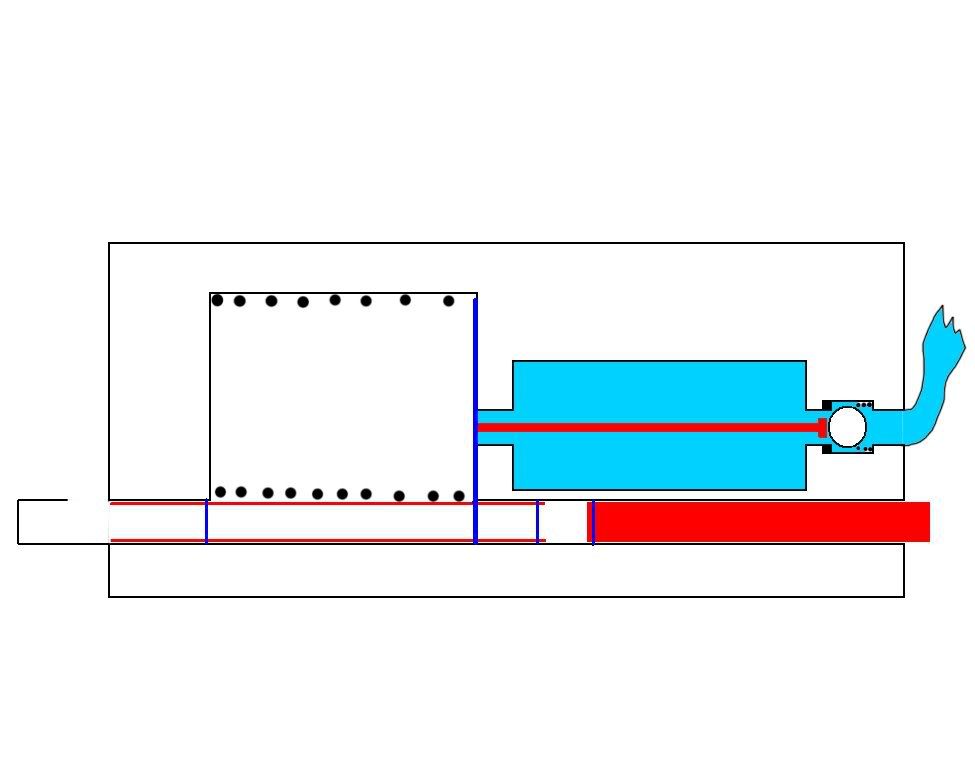

This is an idea i just came up with for a slightly different blow forward bolt design. It is rougly the same as th other blow forward bolt designs on here except the air inlet is above the bolt rather than behind it, the dark blue parts of the diagram are where it seals, the light blue is air, black is casing and red is the bolt. When air is let in the large blue seal which is attached to the bolt moves forward taking the bolt with it, as it moves forward the chambers start to fill and the small ball moves forward blocking the air flow once the chamber is filled, the large blue seal continues to move until the hole in the bolt is exposed and the air rushes out, firing the projectile, the spring infront of the large blue seal pushes the whole mechanism back untill the red rod knocks the small ball back letting more air into the beginning chamber, and starting the whole process again. Another possibility would be instead of using springs, have a motor with a cam setup connected to the back of the bolt and move it by electricity.

It is quite complicated, and would require alot of seals to get it to work, but I think its feasable.

Posted: Sun Aug 03, 2008 5:26 pm

by POLAND_SPUD

no offence but it's difficult to understand.. try to arrenge the text in paragraphs becasue it's difficult to read as well (well at least for me)

it does seem quite complicated and I suppose that you are right that having a lot of seals and making it seal good will be a PITA

See what others will tell you about it but IMO it's not feasible at all

Posted: Sun Aug 03, 2008 5:39 pm

by Hailfire753

It seems to me that it is the same as JSR's failed auto blow-forward bolt, except it is not inline. You may have problems with it cycling.

However, that just gave me an idea for a blow forward bolt that uses chamber pressure to open, but closes when the chamber is fired.

Posted: Sun Aug 03, 2008 6:57 pm

by jackssmirkingrevenge

Hailfire753 wrote:It seems to me that it is the same as JSR's failed auto blow-forward bolt, except it is not inline. You may have problems with it cycling.

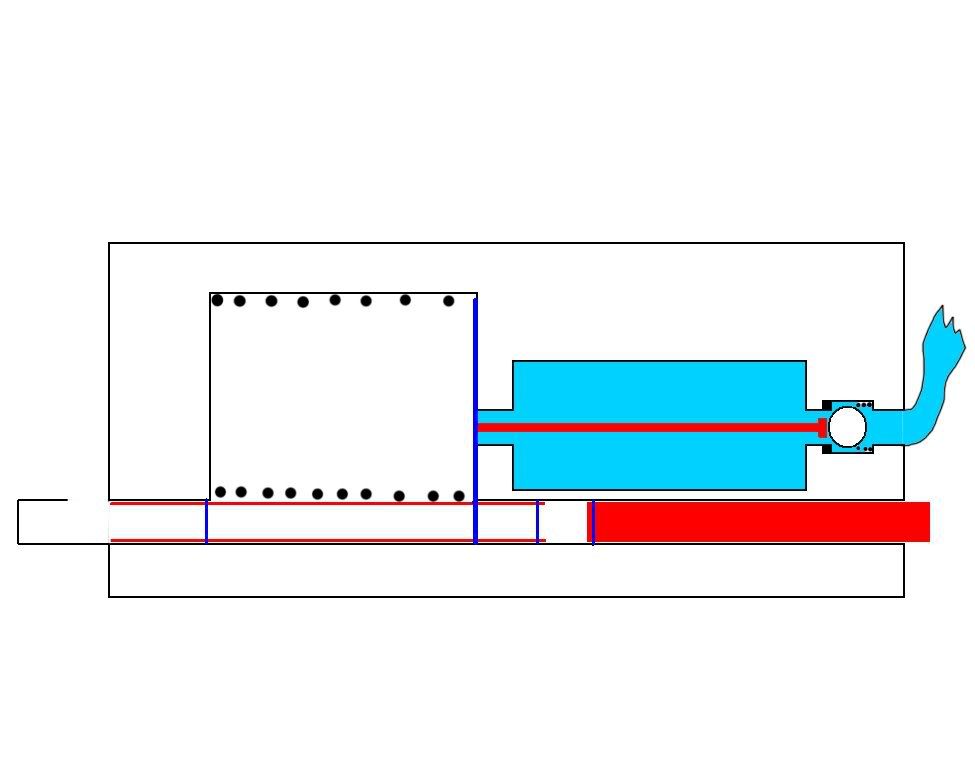

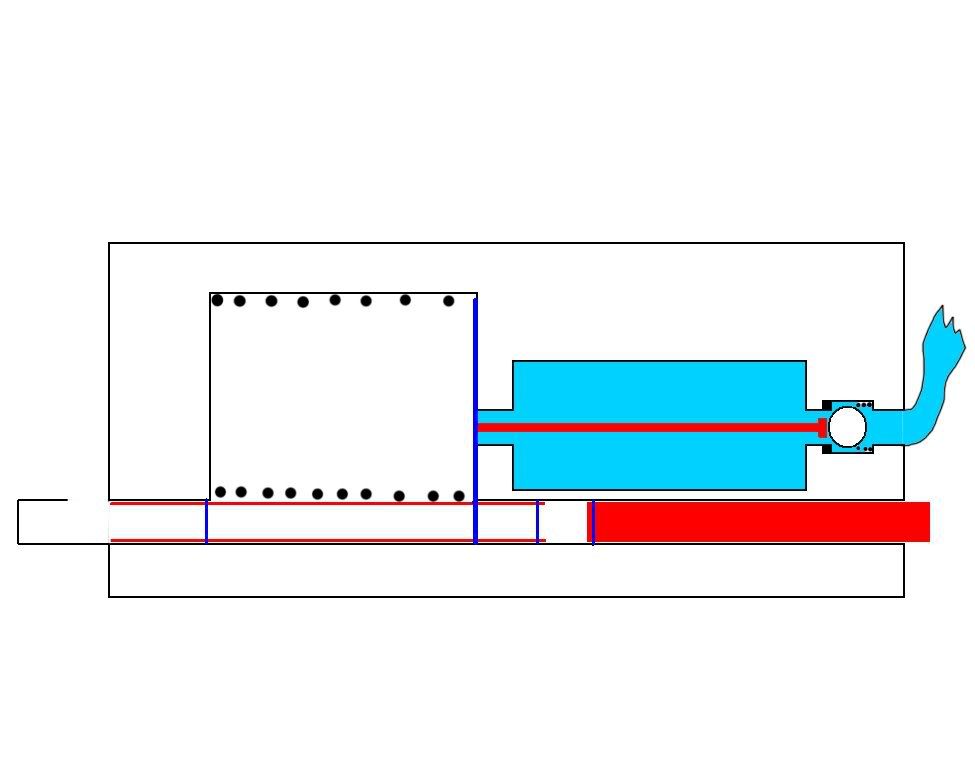

Indeed, seems like a needless complication of this design:

Posted: Sun Aug 03, 2008 7:15 pm

by newbmatic

nice design and ideas but just as JSR said it really is just complicating simple design

but anyways still looks pretty cool

Posted: Mon Aug 04, 2008 12:56 am

by trollhameran

the reason why I designed it like that is so that you can connect a motor to the bolt via the large red block, which would allow you to have better control over the cycling.

Posted: Mon Aug 04, 2008 4:07 am

by jackssmirkingrevenge

trollhameran wrote:the reason why I designed it like that is so that you can connect a motor to the bolt via the large red block, which would allow you to have better control over the cycling.

I had made an attempt at electric drive that was a little less complex, have a look

here. This would work with a powerful enough motor/solenoid, but I'm keen on having a purely pneumatic system which is why I never processeded with the design.

Once you're adding external power, there are other possible configurations, such as a

rotating breech or a

vertically reciprocating breech.

Posted: Mon Aug 04, 2008 4:55 am

by trollhameran

That rotating breach could possibly make for an interesting modification to the standard vortex guns.

I think my design would be hard to make without machining tools, so I think ill keep thinking and trying to make a simpler auto.

Posted: Mon Aug 04, 2008 4:58 am

by jackssmirkingrevenge

trollhameran wrote:That rotating breach could possibly make for an interesting modification to the standard vortex guns.

Most definitely - instead of a constantly open valve, the barrel is effectively blocked until it's time to fire, meaning pressure has time to build up in the BB chamber between shots, therefore more power per shot.

Also, by adding a rheostat into the circuit, you also have an infinitely variable rate of fire, not to mention much greater reliability.

Posted: Mon Aug 04, 2008 7:53 am

by trollhameran

perhaps that will be my next project then.

because the barrel is blocked when its not time to fire, it should use up less air as well, providing the rotating block is a fairly good fit in the chamber.

Posted: Wed Aug 06, 2008 1:32 am

by agentsmithbob

jackssmirkingrevenge wrote:Indeed, seems like a needless complication of this design:

Hey jack, did you ever get this design going? I've been keeping track of a lot of your work on this site but can't ever remember seeing this in action.

Posted: Wed Aug 06, 2008 2:12 am

by trollhameran

I dont think he did get it to work, I think he said it cycled to fast or not at all.

Posted: Wed Aug 06, 2008 3:43 am

by jackssmirkingrevenge

agentsmithbob wrote:Hey jack, did you ever get this design going? I've been keeping track of a lot of your work on this site but can't ever remember seeing this in action.

What I had actually made was the

pop-off variation of that design, the progress of the protoype can be seen in

this thread. I never took the time to fine tune it and make it work, however I would like to try out the original idea, with the bolt also acting as a hammer to knock the check valve open directly. Unfortunately, I'm away from my workbench for most of this year so it's not going to happen any time soon.

trollhameran wrote:I dont think he did get it to work, I think he said it cycled to fast or not at all.

That was

this design

Posted: Wed Aug 06, 2008 3:42 pm

by trollhameran

Sorry my bad jack, got mixed up between the two designs.

Posted: Thu Sep 11, 2008 5:34 pm

by PinHead

jackssmirkingrevenge wrote: I had made an attempt at electric drive that was a little less complex, have a look

here. This would work with a powerful enough motor/solenoid, but I'm keen on having a purely pneumatic system which is why I never processeded with the design.

Once you're adding external power, there are other possible configurations, such as a

rotating breech or a

vertically reciprocating breech.

In response to that, JSR, have you considered using some type of air-powered turbine for a motor, with the exhaust from the turbine being your source of pressure, or something like that? I realize that the thing would probably spin waaaay too fast with that kind of pressure, but it's an idea to work with.