Page 1 of 1

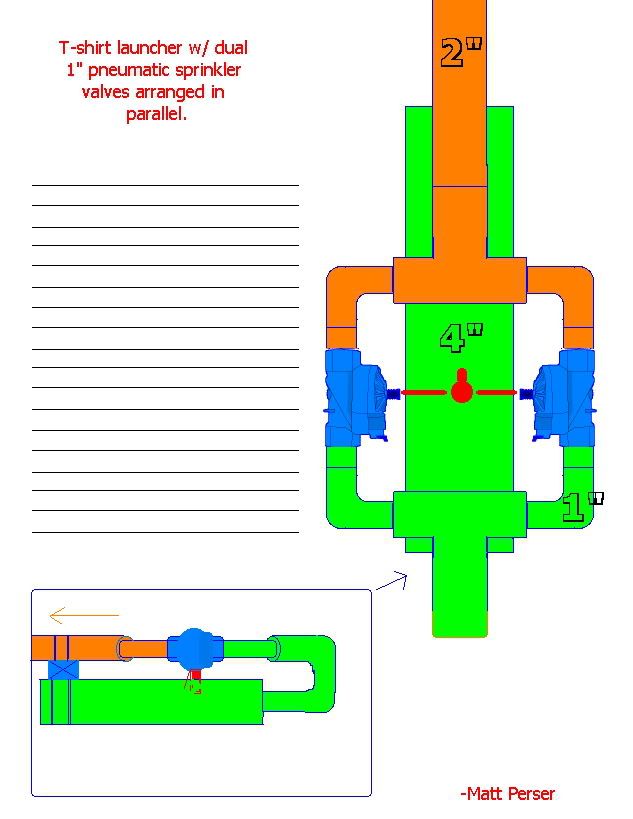

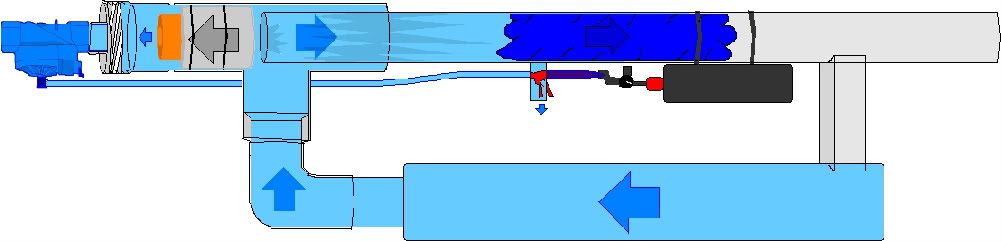

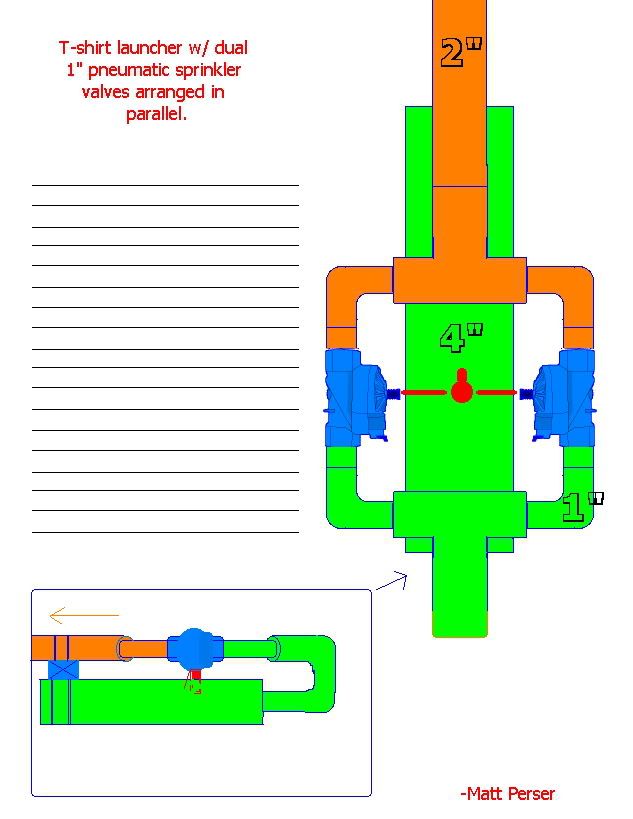

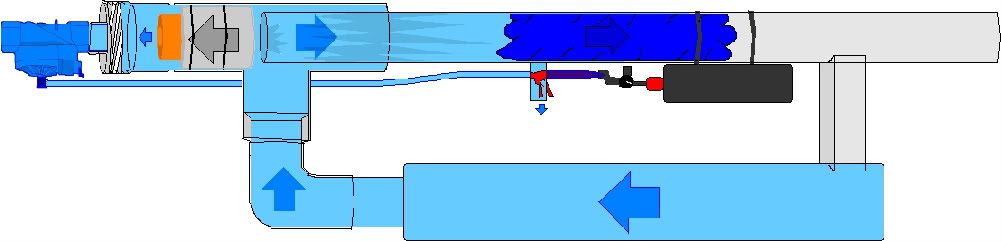

Dual sprinkler t-shirt cannon.

Posted: Sat Mar 07, 2009 9:19 pm

by kiwi of nitro

Is this a viable design? How would you do it? I was considering making a piston valve...

Posted: Sat Mar 07, 2009 9:39 pm

by FishBoy

if you want to do it like that, go for it, it should work well. I'm not sure if you would want a 2.5" instead though, your call. Just make sure to use pressure rated pvc. (diameters above 2" can be hard to find)

Posted: Sat Mar 07, 2009 9:48 pm

by sgort87

It'll work just fine, but I would make the whole thing shorter by facing those orange elbows downward adding another orange elbow to each, and have the sprinklers under the barrel level and inline with the chamber.

If you don't want them on the bottom, you can shorten it up and save yourself a couple dollars by facing that green tee downward and taking out one of those elbows.

Actually, I think it would be pretty bad ass to see either of those ways done, but with the tee facing 45 degrees downward and towards the muzzle, and using another 45 on the bottom to pipe to the chamber.

Posted: Sun Mar 08, 2009 12:04 am

by Daltonultra

Actually, you could save yourself a bit more money by rotating the sprinklers 90* so they form the vertical section of the rear. Then you're rid of two large elbows. That's about $12 you save, and the entire gun is about a foot short and about half a pound lighter.

You can complete the gun by adding an extra barrel support towards the rear of the chamber and setting whatever trigger you use into it. That way you reach through the back between the sprinklers to grip the back support as a pistol-grip.

Posted: Sun Mar 08, 2009 12:08 am

by sgort87

He's still gotta make turns even if the sprinklers are vertical. I'd avoid putting them there though because it would make the launcher obnoxiously tall.

Posted: Sun Mar 08, 2009 2:09 am

by Daltonultra

Managing the height of the gun wouldn't be too hard with the elbows on either end of the sprinklers. Just angle the vertical section forward or back until you get the height right.

Decide how tall you want the gun, cut two matching barrel supportsof the desired height, then assemble the sprinklers and elbows. Put the ends in the tees without gluing them in, and slide the barrel forward or back til it sits flush on both barrel supports. Strap it down with a couple hose-clamps, then glue the elbows into the tees. Voila.

Posted: Sun Mar 08, 2009 3:55 pm

by psycix

Is this a viable design? How would you do it? I was considering making a piston valve...

When you can get sprinklers for a low price and do not bother about the dead volume between the sprinklers and the projectile then yes, it is a viable design.

I, however, would build a piston valve and use one sprinkler to pilot it. Maximum performance, lower cost.

He's still gotta make turns even if the sprinklers are vertical. I'd avoid putting them there though because it would make the launcher obnoxiously tall.

No, you will be doing that rotation on where the elbows shove into the T-pieces.

I agree with daltonultra on making the sprinklers vertical.

When you do it that way, you are using the T-pieces to rotate it instead of the 90* elbows. More efficient use of parts.

Also this makes the gun more compact (longer barrel length)

You should note that this construction is somewhat weak and that a proper barrel support is necessary. If you fire it without a strapping the barrel to the chamber, there's a good chance that the flexing will cause a failure.

Posted: Fri Mar 13, 2009 4:50 am

by kiwi of nitro

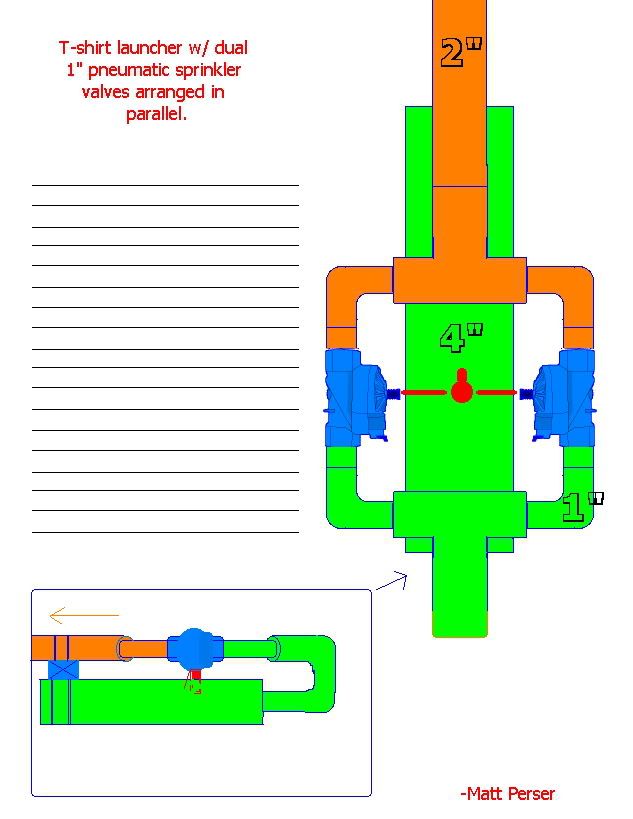

Can I make a 3" piston valve out of a 4" tee? And will a sprinkler valve thread into a clean out plug? How does that look?

Posted: Fri Mar 13, 2009 5:25 am

by inonickname

Why's the blowgun exhausting into/near a chamber? Oh well..

Cleanout plugs are usually not pressure rated and are often difficult to airtight. Go for Sch. 80 Pw if you can find it, but a reducer (threaded) will work better if you can get the right sizes.

Posted: Fri Mar 13, 2009 3:09 pm

by psycix

You should not use a cleanout plug. The piston can do some serious hammering on the back end and thus that needs to be very strong.

As far as I can see, you are using the blowgun to pilot the sprinkler and some sort of CO2 tank to fill via the same line. Know that that brings some dangers right? Popoff valve would be safe.

Also try to keep the hose as short as possible.

Posted: Sat Apr 04, 2009 7:59 pm

by kiwi of nitro

I made that at like 2am a few weeks ago, Didn't think about using a threaded reducer bushing or female/male adapter.

I just wanted to be able to get the piston out for maintenance if needed.

I may not need to ever remove the piston if machine it from a solid pvc rod and use neoprene on the seal... A good bumper would help too...