full-auto piston valve and bolt combination revisit

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

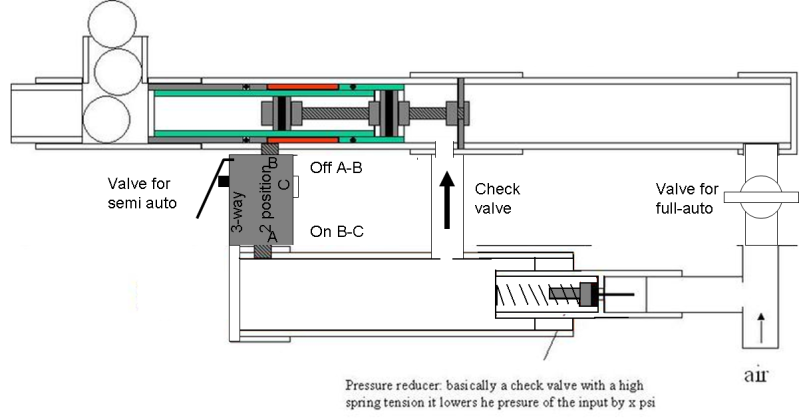

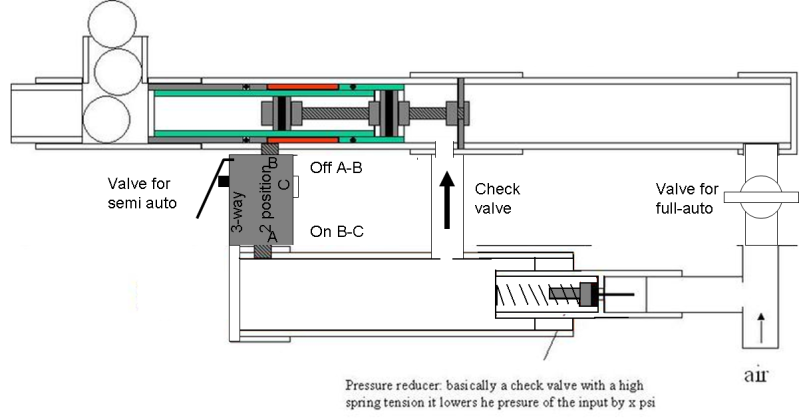

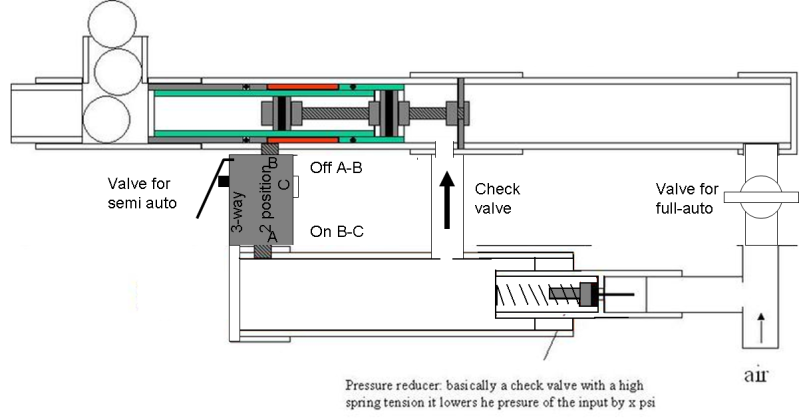

so back in spudfiles contest of 2007 clide came out of nowhere with his fully automactic HEAR valve after brain storming through designs for valve, the thought when around for piston valve like the hear that would act as a valve and a bolt. one day while explaining to one user why his design for a blowforward bolt/piston valve would not hold the piston/bolt back due to the lack of cross sectional area in the pilot, I was inspired and modified the design into a fully-automatic-piston-valve/blow-forward bolt original thread . Recently I have revisited the design and modified it yet again so that it is semi automatic or fully automatic, what do you guys think

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

great minds think alike

hmmm it doesn't function as a 3 way valve... that can be fixed easily

hmmm it doesn't function as a 3 way valve... that can be fixed easily

Children are the future

unless we stop them now

unless we stop them now

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

Wut?POLAND_SPUD wrote:great minds think alike

hmmm it doesn't function as a 3 way valve... that can be fixed easily

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

the valve does not cut it's own air supply when it firesit doesn't function as a 3 way valve

Children are the future

unless we stop them now

unless we stop them now

- jackssmirkingrevenge

- Five Star General

- Posts: 26179

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 543 times

- Been thanked: 321 times

I abhor this obsession with complicating things

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

do you have a fully/semi automatic bolt/valve design that's simpler?

it's not that complicated it's an integrated bolt and a piston valve all in one an auto piston and a blowforward bolt may be easier to understand but the parts are not integrated there are more parts, in this there is only one moving part that obtains full auto,

originally I wanted to use a spring so there would only be 3 seals like the hear valve, but I doubted I could get a strong enough spring so I went with an air spring and a simple check valve with a tight spring would automatically adjust the reduce the pressure so the gun could operate at any presure without adjustment. now I realized I could do semi auto with a valve attached to the airspring

I challenge you to design a simpler one with as much or more function

edit: does this design suit your tastes sir, and btw arn't you working on a computer controlled sentry

it's not that complicated it's an integrated bolt and a piston valve all in one an auto piston and a blowforward bolt may be easier to understand but the parts are not integrated there are more parts, in this there is only one moving part that obtains full auto,

originally I wanted to use a spring so there would only be 3 seals like the hear valve, but I doubted I could get a strong enough spring so I went with an air spring and a simple check valve with a tight spring would automatically adjust the reduce the pressure so the gun could operate at any presure without adjustment. now I realized I could do semi auto with a valve attached to the airspring

I challenge you to design a simpler one with as much or more function

edit: does this design suit your tastes sir, and btw arn't you working on a computer controlled sentry

- Attachments

-

- beatthisauto.PNG (6.81 KiB) Viewed 3806 times

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

I am afraid this won't work... first of all becasue the bolt won't return to its original position (it could if there was a vent hole but that wouln't make sense)

secondly, you need to cut off HPA in a balanced or almost balanced way

secondly, you need to cut off HPA in a balanced or almost balanced way

Children are the future

unless we stop them now

unless we stop them now

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

I'm not using HPA, it's under 100psi, in terms of piston valves the red area acts as the pilot, which do you think will pressurize first the tiny red volume or the big chamber volume, you don't need to completly cut off flow to the chammber because the pressurization is much slower, how do you think you fill a sprinkler valve gun? air connected to the chamber doesn't mean that the piston can't reset

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

I was referring to the one in the second pic...

anyway I also think that simplicity is important...

but the only question is how far you should go in simplifying stuff

you know, the unicycle is simpler than the bicycle but for some reason the latter seems to be more popular

here if the air source is not cut off you lose air... fixing that does not increase complexity up to a point where it would cost to much, weight too much or would decrease reliability

anyway I also think that simplicity is important...

but the only question is how far you should go in simplifying stuff

you know, the unicycle is simpler than the bicycle but for some reason the latter seems to be more popular

here if the air source is not cut off you lose air... fixing that does not increase complexity up to a point where it would cost to much, weight too much or would decrease reliability

Children are the future

unless we stop them now

unless we stop them now

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

actuly the second picture operates on the auto valve design, the sudden exposure to a greater surface area make the piston move fast into the open position then the drop in pressure is more than enough for the spring to handle, an additional chamber and flow regulator also works

- jackssmirkingrevenge

- Five Star General

- Posts: 26179

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 543 times

- Been thanked: 321 times

Do NOT insult me with your flatulence machines Sir!

Isn't that basically what I suggested here?

I had also thought up a pop-off version that would be simpler and more powerful, but in those days I hadn't expermented enough to know how to make it work. Maybe with my accumulated knowledge (OF FAIL!) I should give it another go.

As I was discussing with Brian recently, the critical element is that the porting is exposed when the piston is at rest, in short:

In this case, the porting could be a slightly undersized piston. Flow around it would have to be significantly less than flow from the seat, for example imagine 1/4" seat and a 1/2" chamber. Area through the seat would be 0.049 square inches. This means that the flow between the piston has to be less than 50% of that for effective function, the chamber area will be around 0.196 so the difference in area between should be around 0.02-0.01 square inches, so a piston of say 0.48" diameter (in a 0.50" chamber) will do nicely. It also conveniently saves you the hassle of having everything concentric.

There are other ways of combining the pop-off piston with a breech sealing mechanism:

Well yes, but in the least complicated manner possible Still waiting for the parts to accumulate, in the meantime I get to pooh-pooh other people's ideas

Still waiting for the parts to accumulate, in the meantime I get to pooh-pooh other people's ideas

Yes, this might be worth trying, I've edited you diagram somewhat:

Isn't that basically what I suggested here?

I had also thought up a pop-off version that would be simpler and more powerful, but in those days I hadn't expermented enough to know how to make it work. Maybe with my accumulated knowledge (OF FAIL!) I should give it another go.

As I was discussing with Brian recently, the critical element is that the porting is exposed when the piston is at rest, in short:

In this case, the porting could be a slightly undersized piston. Flow around it would have to be significantly less than flow from the seat, for example imagine 1/4" seat and a 1/2" chamber. Area through the seat would be 0.049 square inches. This means that the flow between the piston has to be less than 50% of that for effective function, the chamber area will be around 0.196 so the difference in area between should be around 0.02-0.01 square inches, so a piston of say 0.48" diameter (in a 0.50" chamber) will do nicely. It also conveniently saves you the hassle of having everything concentric.

There are other ways of combining the pop-off piston with a breech sealing mechanism:

Aren't you working on a computer controlled sentry

Well yes, but in the least complicated manner possible

Yes, this might be worth trying, I've edited you diagram somewhat:

- Attachments

-

- itworksmateworksyeahthefatonebalancesoutthetwoskinnyones.jpg (9.58 KiB) Viewed 3727 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

really, but then it doesn't take nearly as much advantage of the increased surface area to create a rapid opening. while this may work better for you in practice most likely because of the increase in counter-acting mechanical pressure as the spring is compressed further, once addressed it can be made more effective by increasing the weight of the piston so it will hold open longer thus close with a lower pressure. what I wish to say is that you shouldn't completely forget the idea of an un-exposed auto piston because otherwise there is not enough movement in the piston to cycle the bolt. theoretically it should be possible although it may work best with larger systems where proportionally the input flow is less, which is what this design is for, I specifically designed it so it could be made with pvc pipe.As I was discussing with Brian recently, the critical element is that the porting is exposed when the piston is at rest, in short:

It has to be that way, or else face resetting problems.

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

loltworksmateworksyeahthefatonebalancesoutthetwoskinnyones.jpg

JSr but what kind of flow coef can you get with it ? and where's efficiency in it??

Children are the future

unless we stop them now

unless we stop them now

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

and normally that would be due to the pressure from the input or chamber being still relatively high, but with a larger volume chamber and system with a relatively slower input it could workpsycix wrote:It has to be that way, or else face resetting problems.

perhaps this might work since it has a larger chamber volume and some volume around the seat for left over pressure (maybe a one way sealing floating o-ring design around the piston might help also) and it utilizes only a small distance for piston movement

- Attachments

-

- auto piston on bolt.PNG (7.69 KiB) Viewed 3642 times