jackssmirkingrevenge wrote:Airgunners in the UK are painfully aware of this effect, they are limited to a strict 12 ft/lbs muzzle energy level above which an air rifle is considered to be a firearm which needs a license, failure to own the latter means a potential 5 year stretch at her majesty's pleasure.

I can see that my reply wasn't phrased right. The point wasn't that projectile mass increases efficiency (others have noticed that); the point was that it could be used to compensate for slow valves. The two are obviously related.

If you look at my first post in this thread, all I say is that "[if] the projectile is heavy enough then performance can be nearly independent of valve flow." I say nothing about efficiency. This was the "performance regime" that I referred to; the one where the projectile is so heavy that the chamber and barrel pressures are essentially identical. This basically means that performance is independent of the valve performance, use of a detent, friction, etc. I am not aware of any similar statements.

With respect to my statement about high speed guns, I meant more specifically that even a perfect valve isn't fast enough, so you can compensate with something else like a detent or heavy projectile. Efficiency also comes into play here, but that wasn't my larger point.

Again, to reiterate, my point was that heavy projectiles allow you to compensate for slow valves, and that there is a certain regime where basically how fast your valve is doesn't matter much.

jackssmirkingrevenge wrote:True, however from the same launcher a heavier projectile will have a lower muzzle velocity and correspondingly larger rate of projectile drop over a given distance, for which reason if long range shooting or target penetration is the goal this is not the ideal solution.

Right. Don't lose track of your larger goals, whatever they may be. I'm just saying that heavy projectile can allow for worse valves to be used without affecting the performance and that people should consider this in design.

Technician1002 wrote:I was referring to the math where the assumption of a 1:1 ratio is best. A chamber and barrel volume of 700 cubic inches was the math. This test showed a longer barrel was better.

A C:B ratio of 1:1 is plainly wrong in most cases, so I'm not surprised you found differences with real world testing.

Technician1002 wrote:If trying the other math for no chamber pressure, the 60 PSI would expand out way beyond the length of the barrel used. Acceleration fell off way before the chamber volume expanded out to the volume required to be no pressure left.

GGDT models the flow losses quite well once you find your valve efficiency. It took some time working backwards from muzzle velocity, projectile positions, and such to find my valves to get a match with GGDT's graphs. I have a thread on that.

Could you be a little more precise? What is "the other math"? Boyle's law? Boyle's law is better than assuming a 1:1 ratio, but it's still plainly wrong in most cases.

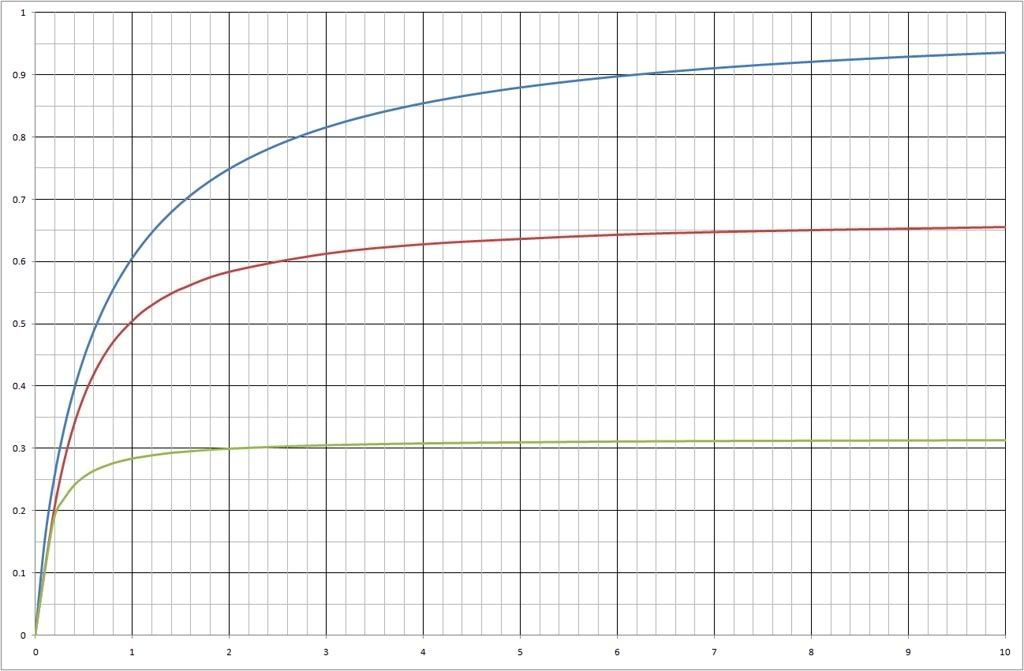

Using any sort of process relationship assumes that the chamber and barrel pressures are approximately the same. We know this isn't true in general. As I've alluded to before, this assumption is valid when the dimensionless projectile mass is above a certain amount (i.e. when the projectile is heavy enough). The critical dimensionless projectile mass is a function of the valve performance, friction, and other factors.

My non-dimensional simulation is very similar to GGDT at the moment, and a theoretical equation based on adiabatic process relationships fits the data in the critical regime very well.

CB = (1 + Vd*) / ((Pc* / (1 + Pf*)) ^ (1 / k) - 1)

Pf* = Pf / Patm (Pf is the "pressure of friction" much like how GGDT does friction)

Vd* = Vd / Vb (Vd is the "dead" volume)

k 0s the ratio of specific heats (1.4 for air)

Remember, as I've noted, this only applies when the pressure in the barrel and chamber are approximately equal. That was not the case in your tests Technician.