Page 2 of 3

Posted: Sat Dec 04, 2010 6:42 pm

by Lockednloaded

I had the very problem I feared... filling pilot side through a 1/8" paintball QD, I turned on the tank. with the lowest flow, I got a steady popping every second or two, so I turned it up and air just hissed out the pop-off

It seems filling chamber side is the only way to fix this

:EDIT:

I figured out the problem! it was the adjustable pop-off, so now with a standard pop-off I'm getting the DAKKA DAKKA I wanted

I do have another question though, what size ball bearings would fit well in 1/2" SCH 80 PVC, 1/2" bearings were too small

Posted: Sun Dec 05, 2010 12:31 am

by jackssmirkingrevenge

Sweet, video please!

What's the internal diameter of your barrel?

Posted: Sun Dec 05, 2010 12:52 am

by Lockednloaded

I don't have a barrel or feed setup yet, but I would like to use 1/2" bearings. I have yet to find a pipe with an OD close to .5 though...

Posted: Sun Dec 05, 2010 6:23 pm

by Lockednloaded

:BUMP:

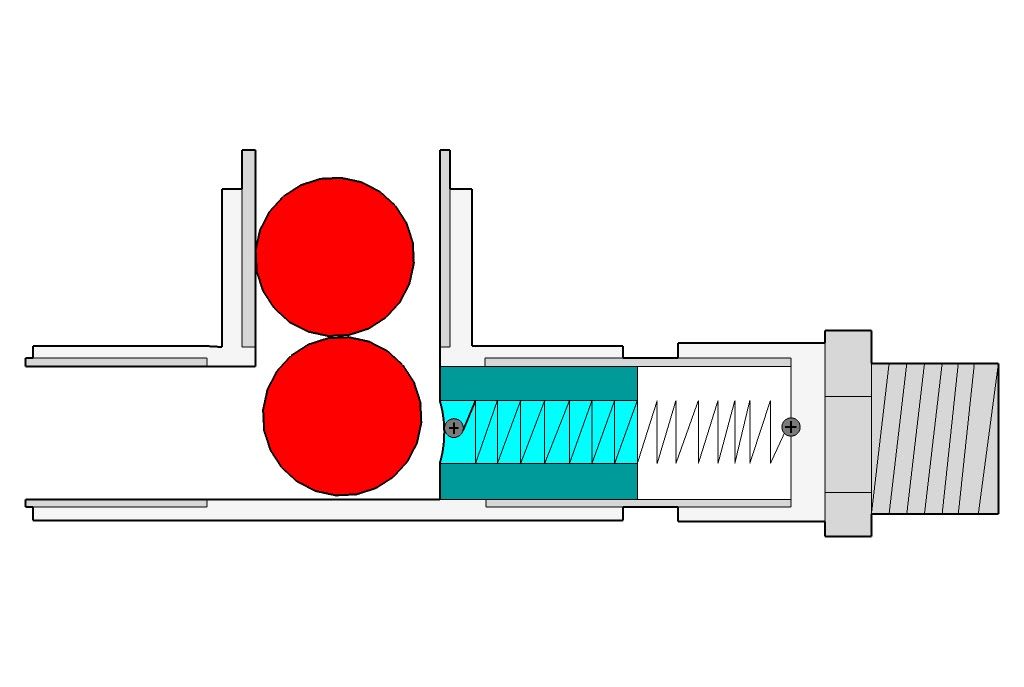

bumping for pictures of the setup sans loading mech, the "barrel" currently attached is filled mainly with steel wool and acts as a silencer to quiet the DAKKA DAKKA. I feed un-regged CO2 through the small QD at the bottom of the tee

Who woulda thought that a full auto gun could be cheaper than a semi auto? It turns out this way because I didn't have to buy a DCV, a paintball regulator, or an air ram (I know an air-ram is not a must, but I would've built a semi with one)

Posted: Sun Dec 05, 2010 6:34 pm

by Gun Freak

Wow... Looks amazing dude... Is that a schrader on the back? And what pressure pop off it is?

Posted: Sun Dec 05, 2010 7:01 pm

by Lockednloaded

Thanks, this is just a preview of whats to come

The pop-off is set at 125, but I have one set at 90, and another at 200. A quick note of pop-offs: never use adjustable pop-offs for full auto, they don't work. Yes, that is a schrader, I need to get a proper elbow so I can ditch the tee. The schrader is just a plug

Posted: Sun Dec 05, 2010 7:21 pm

by Gun Freak

Shame the pilot is so big... You could use a male tee with a regular elbow to the pop off, that could lower the pilot volume a bit... is the 200 psi pop-off standard? Looking forward to the loading mech...

Posted: Sun Dec 05, 2010 8:00 pm

by Lockednloaded

The pilot volume is teetering one the larger side, but the pop-off has proven its uncanny ability to pilot valves with much larger pilot volumes; larger QEVs, SVs, and even homemade valves. I don't get what you means by "standard" sorry. The loading mech won't be much to look at; a sten style mag and a detent

Posted: Mon Dec 06, 2010 1:00 am

by jackssmirkingrevenge

Glad it's working well, and I agree it can afford some cleaning up. A word about pilot volume though, I found that making the pilot volume too small could actually not provide sufficient air for the safety valve to "pop" effectively, so it's not necessarily a bad thing.

Posted: Mon Dec 06, 2010 8:50 am

by Lockednloaded

I would like to add a more comfertable trigger, along with a high pressure needle valve. The detent should also be cured tomorrow afternoon, so check in here later for some major progress or epic fail

Posted: Mon Dec 06, 2010 6:31 pm

by Gun Freak

Lockednloaded wrote:I don't get what you means by "standard" sorry.

Non-adjustable.

Posted: Mon Dec 06, 2010 9:43 pm

by Lockednloaded

The detent failed miserably, I'm looking into other alternatives now. Please give me any ideas or links to good technical examples if you can, thanks

Posted: Tue Dec 07, 2010 1:12 am

by jackssmirkingrevenge

How did it fail exactly, multiple feeds?

Posted: Tue Dec 07, 2010 8:38 am

by Lockednloaded

It was an adjustable ball detent, but it either double-fed horribly or chopped up paintballs in the breech. I worked on it a while, but I couldn't find a sweet spot[/list]

Posted: Wed Dec 08, 2010 10:02 pm

by Lockednloaded

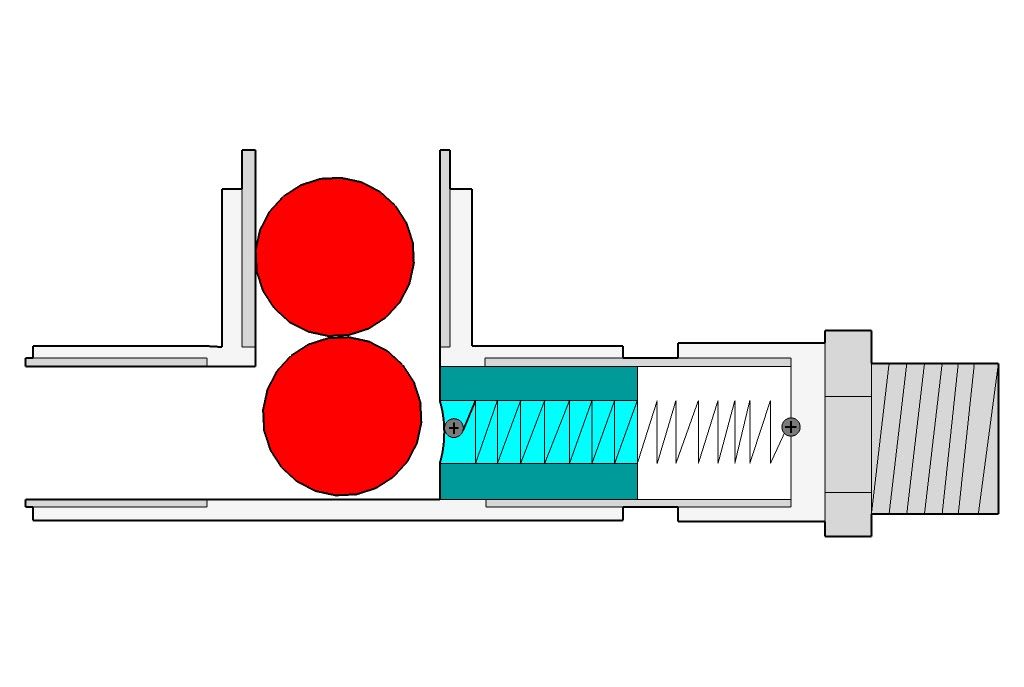

After the failure of the detent, I've thought up a simple BFB. Basically what I've got here is a standard 3/4" CPVC tee, pipe, and male adaptor. The actual BFB os a cast epoxy piston with a 1/2" hole drilled through the center. A screw is put across the hole to both increase SA and to hold the extension spring

Hope its clear for ya