Page 1 of 1

Piston Valve Troubleshooting

Posted: Wed Nov 16, 2011 11:29 am

by ktap

I currently am making a new all metal spudgun, however this is my first piston valve design.

Currently, the spudgun is completely finished, the only problem is that the piston valve is not working. Currently I air it with a 12g. seems fine, has no leaks. I open my pilot valve (a 1/2" ball valve), and nothing happens.

Some important specs: It is a coaxial barrel sealing piston valve built in a 1" steel "T". I have about a 1 to 1.2 barrel to chamber ratio.

My piston is made of 3 aluminum washers I turned on a lathe. There is about 9 thou clearance between the rear piston washers and the ID of the valve. Between two of the washers I have sandwiched a rubber gasket that is the same OD as the piston washers. The last washer has a rubber face that seals the barrel. The whole piston weighs 86grams.

Posted: Wed Nov 16, 2011 11:33 am

by jackssmirkingrevenge

Pictures would help us help you.

Possible problems are too much leakage past the piston, too big pilot volume, too heavy piston, too close piston diameter to barrel inner diameter, those are the usual suspects.

and nothing happens.

Do you mean it all leaks out of the pilot without firing?

Posted: Wed Nov 16, 2011 11:57 am

by ktap

^Exactly. I'll work on getting some pics.

Posted: Wed Nov 16, 2011 4:01 pm

by Mr.Tallahassee

A coaxial built in a Tee? Please do post pictures.

Posted: Wed Nov 16, 2011 4:28 pm

by ktap

Hmmm, looking at how you guys define coaxial on this forum, I detract that statement. I actually have got the valve to work, only problem is the rubber gasket on the seal face keeps falling off the piston after 1 actuation. So I've decided to just attach the gasket to the barrel lip itself.

Posted: Wed Nov 16, 2011 4:51 pm

by Gun Freak

If you're going that route make sure the hole in the gasket is the same size as the ID of the barrel so you don't restrict flow. But if you use a bolt and washer to hold it on you shouldn't be having that problem.

Posted: Wed Nov 16, 2011 4:56 pm

by ktap

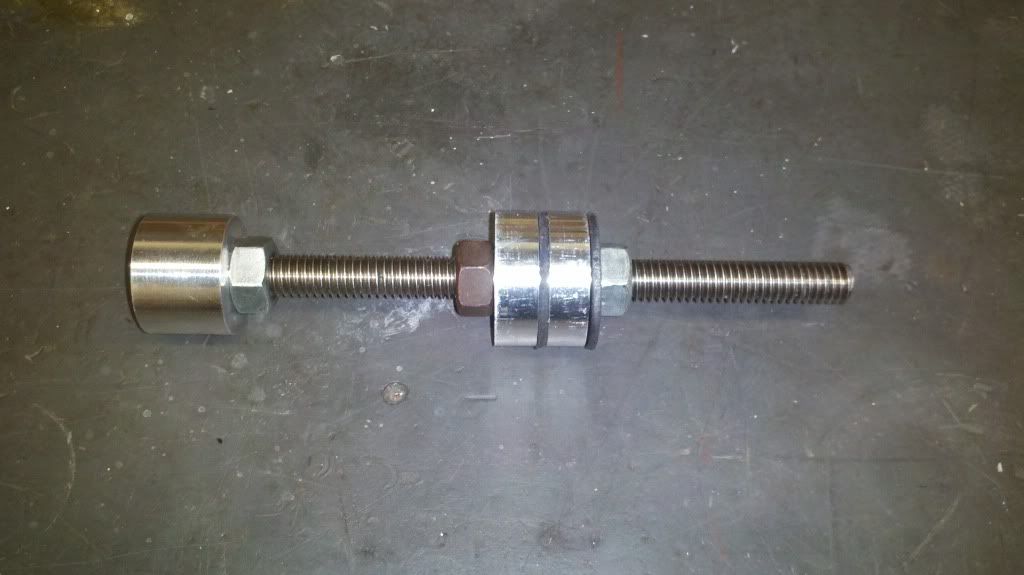

The piston itself.

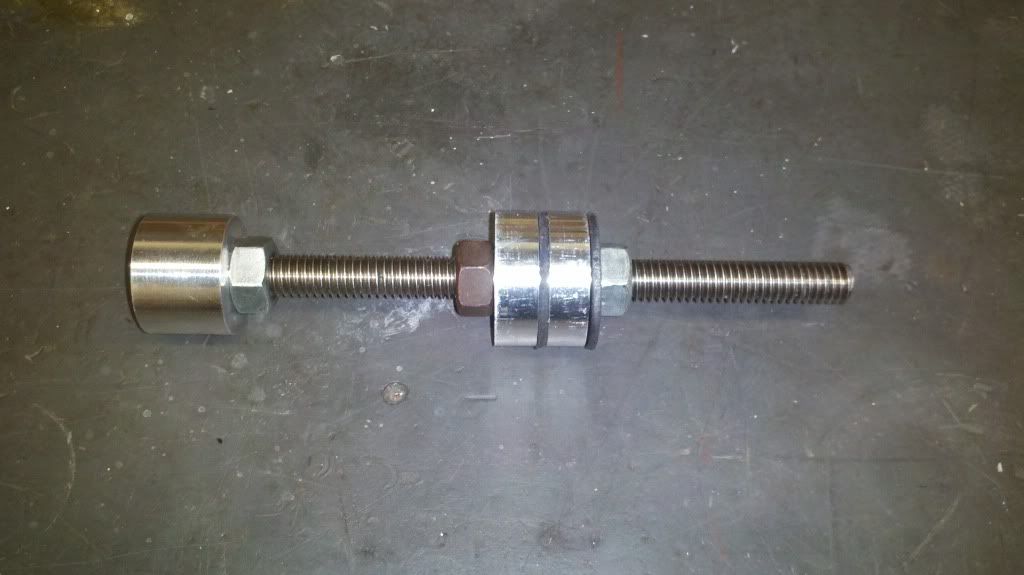

Panorama of the entire assembly.

Posted: Wed Nov 16, 2011 5:02 pm

by MrCrowley

ktap wrote:Hmmm, looking at how you guys define coaxial on this forum, I detract that statement. I actually have got the valve to work, only problem is the rubber gasket on the seal face keeps falling off the piston after 1 actuation. So I've decided to just attach the gasket to the barrel lip itself.

The gasket needs to be bolted on with a large washer holding it down and preferably epoxy used to glue it to the piston as well. Do that and you shouldn't have a problem. Then again, epoxying an o-ring to the seat shouldn't be a problem either.

Posted: Wed Nov 16, 2011 5:24 pm

by ktap

So essentially I need some sort of fastener. Just glue will probably not cut it? I see no reason to add a nut or anything that will enter the barrel and restrict flow unless I really have to.

Also it is important to note that the washers on the piston are threaded, and do not freely slide on the rod.

Posted: Wed Nov 16, 2011 5:29 pm

by jackssmirkingrevenge

Cut the end of that bolt off and turn off some of the aluminium disk, your heavy piston isn't helping with performance.

As to using glue alone, I only managed with epoxy gripping the sides of the rubber in a cast piston, I would definitely agree with MrC that a washer is needed.

Posted: Wed Nov 16, 2011 6:25 pm

by Gun Freak

Super glue will hold the rubber on for sure.

Posted: Thu Nov 17, 2011 10:12 am

by ktap

Cyanoacrylate glues failed the first battery of seals. I put some high strength epoxy on overnight, we'll see how it goes.

Posted: Thu Nov 17, 2011 2:56 pm

by ktap

Well, epoxy, as always, fixes everything. Works great now. Thanks for the help.

Any 1/2" high pressure QEVs anyone know of? Ball valves are great for troubleshooting at the beginning, but their performance isn't that great.