QEV Help (firing out pilot)

Posted: Sun Dec 18, 2011 12:45 pm

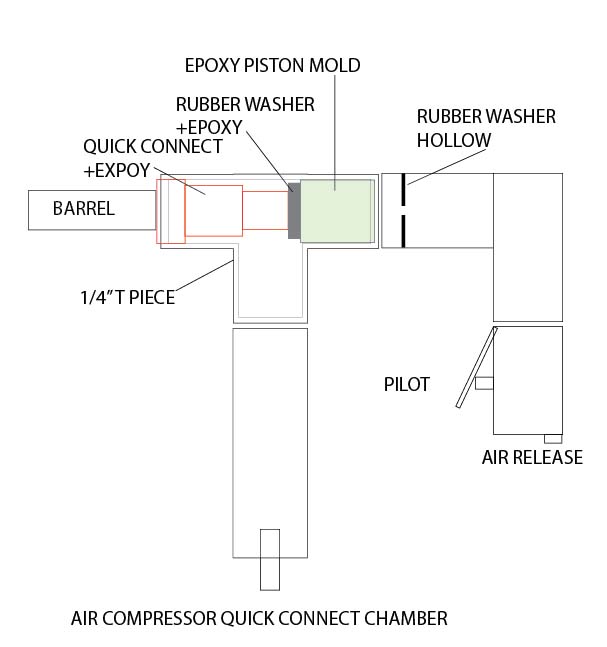

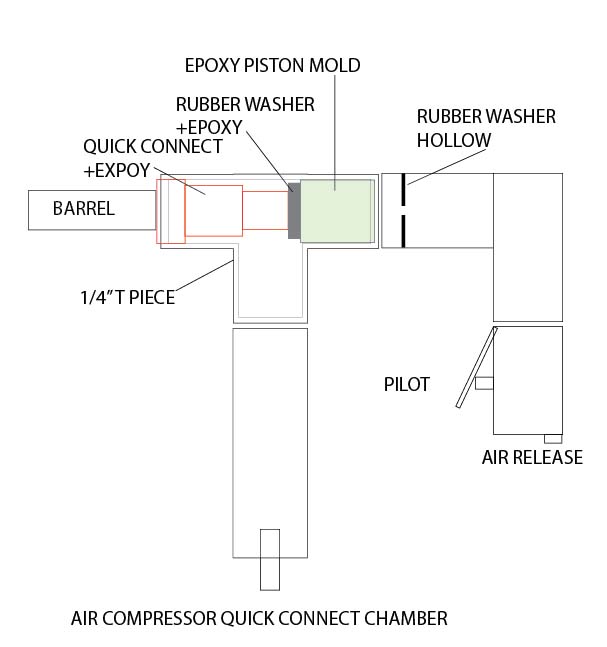

Hey People been researching a lot in the past few months and need a bit of help. So heres my problem, my qev isnt working, its firing out the pilot exit. Heres the thing i made a mock up piston out of wood and glued a rubber washer on the end, it was working fine (about 200 shots) untill the wood started to wear out ( running at 130psi from an air compressor) i sanded the piston to smooth it out and its never fired since.

I figured the piston was too small and the air was equalizing too fast. I have since made a mold out of epoxy its a snug fit with about .2mm play in the shaft but slides freely in the T piece, however its still only firing out the pilot end (feels like 20psi comming out, same as when it was working)

I have tried to

1. make another piston with more play in the shaft( aswell as changing the spring rates and removing the spring all together, normally it would shoot the piston out of place after 1 shot but atleast i knew it worked)

2. Reduce pilot volume by removing some fittings.

Im thinking maybe im not expelling enough air for the pressure to drop, but then again it worked before. Any Ideas guys? sorry about the ranting just trying to be informative. heres some pictures of my setup

length between the piston and washer is about 25mm(tried with and without springs)

my scrappy mock up gun

I got abit annoyed trying to fix this so ive orded and QEV and slide valve pilot from ebay along with some nice 8mmODx6mmID and 6mmODx4mmID barrels got an idea to make a nice pump action reload barrel by sleeving the two.

I still want to work out whats wrong with this QEV, any help will be much appreciated thanks guys.

I figured the piston was too small and the air was equalizing too fast. I have since made a mold out of epoxy its a snug fit with about .2mm play in the shaft but slides freely in the T piece, however its still only firing out the pilot end (feels like 20psi comming out, same as when it was working)

I have tried to

1. make another piston with more play in the shaft( aswell as changing the spring rates and removing the spring all together, normally it would shoot the piston out of place after 1 shot but atleast i knew it worked)

2. Reduce pilot volume by removing some fittings.

Im thinking maybe im not expelling enough air for the pressure to drop, but then again it worked before. Any Ideas guys? sorry about the ranting just trying to be informative. heres some pictures of my setup

length between the piston and washer is about 25mm(tried with and without springs)

my scrappy mock up gun

I got abit annoyed trying to fix this so ive orded and QEV and slide valve pilot from ebay along with some nice 8mmODx6mmID and 6mmODx4mmID barrels got an idea to make a nice pump action reload barrel by sleeving the two.

I still want to work out whats wrong with this QEV, any help will be much appreciated thanks guys.