Page 1 of 2

Internal Regulator for hammer valve pcp

Posted: Mon Aug 27, 2012 2:27 am

by jmez1996

Hey everyone i'm getting a lathe soon and i've been looking at designing a bolt action hammer-valve pcp to machine on it (i've had some experience with metal lathes).

One of the main areas i would like to address is accuracy (perhaps over some distance). All my guns so far have been qev's and i have noticed there is a lot of vertical bullet drift as the pressure in the chamber drops.

I would like to put a regulator inside the main cylinder of the air tank and be able to set it to let through say 80 psi but no more. Hopefully this will give me steady pressure and steady pellet drop until the air tank drops below that. i am aware that commercial pcp's use something of this sort.

Does anybody know of a design for this which could be made to work at this kind of pressure (it doesn't not have to be adjustable) or an alternative which will give me steady pressure and shots?

Posted: Mon Aug 27, 2012 2:46 am

by jackssmirkingrevenge

Why not look into getting yourself a paintball tank with an internal regulator?

Saves you a lot of hassle, and in my view it doesn't compromised on looks if properly configured:

If you're concerned with long range accuracy, 80 psi in a small bore isn't really going to cut it. A ninja paintball tank regulator can be adjusted down to 450 psi which is within a good range for small calibres. Remember most airguns work in the 2000-3000 psi range, if you want to compete with lower pressures then you need a high flow and very efficient valve system.

Posted: Mon Aug 27, 2012 2:53 am

by jmez1996

jackssmirkingrevenge wrote:

If you're concerned with long range accuracy, 80 psi in a small bore isn't really going to cut it. A ninja paintball tank regulator can be adjusted down to 450 psi which is within a good range for small calibres. Remember most airguns work in the 2000-3000 psi range, if you want to compete with lower pressures then you need a high flow and very efficient valve system.

Sorry by range im talking like 30 yards?

calibre probably .177 because of convenience or possibly .22

I guess i could operate at about 100psi with a small firing chamber because i can only reach around 500psi but im looking for 6+ shots per filling.

Can these paintball tanks be bought online?

Posted: Mon Aug 27, 2012 3:04 am

by jackssmirkingrevenge

jmez1996 wrote:Sorry by range im talking like 30 yards?

In order to have a flat trajectory at that distance you want at least 800-900 feet per second for a half gram 0.177 pellet. I don't have GGDT to hand but I'm pretty sure 100 psi isn't going to give you that in a rifle sized launcher.

I guess i could operate at about 100psi with a small firing chamber because i can only reach around 500psi but im looking for 6+ shots per filling.

Do you have a diving shop or paintball store nearby that can top you up with 3000/4500 psi?

Can these paintball tanks be bought online?

If you're in the US, quite easily:

http://www.ebay.com/itm/Ninja-Paintball ... 3f183f81ea

If not... hmm...

have you thought of air cartridges? Guaranteed consistent shots, can be taken to high pressure and if you have a lathe making a batch of 10 is fairly easy work.

Have a look at

this, still a simple hammer valve

Posted: Mon Aug 27, 2012 3:28 am

by jmez1996

have you thought of air cartridges? Guaranteed consistent shots, can be taken to high pressure and if you have a lathe making a batch of 10 is fairly easy work.

Have a look at

this, still a simple hammer valve

Yeah I am keen to make self contained cartridges but I thought it would be a more difficult project and would leave it till later on. I would like the cartridges to be a sensible size.

what about this regulator and then using my own tank?

http://www.ebay.com.au/itm/NEW-PAINTBAL ... 549wt_1024

Posted: Mon Aug 27, 2012 3:39 am

by jackssmirkingrevenge

jmez1996 wrote:Yeah I am keen to make self contained cartridges but I thought it would be a more difficult project and would leave it till later on. I would like the cartridges to be a sensible size.

I would say it's actually easier than trying to make a PCP if you have machining macilities.

Not that regulator. I tried one, didn't work well at all, even ruined its own gauge. Petitlu on this forum had similar experiences with the same model.

Posted: Mon Aug 27, 2012 4:46 am

by jmez1996

jackssmirkingrevenge wrote:I would say it's actually easier than trying to make a PCP if you have machining macilities.

Okay i might look into that further

Not that regulator. I tried one, didn't work well at all, even ruined its own gauge. Petitlu on this forum had similar experiences with the same model.

Haha okay cheers i won't touch that one.

Nevertheless, What would you think the performance of the design i showed at the start, say .177cal. Tank filled to 400psi, unregulated. the tank being pipe with ID 3cm and about 80cm long so like 565cc or about 35 ci.

i have heard hammer valves perform much better in terms of consistency than qev's

Posted: Mon Aug 27, 2012 5:21 am

by jackssmirkingrevenge

jmez1996 wrote:Nevertheless, What would you think the performance of the design i showed at the start, say .177cal. Tank filled to 400psi, unregulated. the tank being pipe with ID 3cm and about 80cm long so like 565cc or about 35 ci.

i have heard hammer valves perform much better in terms of consistency than qev's

The truth is that most hammer valve PCPs on the market do not have regulators, hammer valves tend to release much shorter "bursts" of air, hence the importance of higher pressures.

All hammer valve airguns without regulators have a "sweet spot" or "heart of fill" as it is sometimes known, an area in the pressure curve where the pressure is consistent. While a QEV will give you a steady decrease of performance, a hammer valve will normally start low, increase the decrease again. This is because more pressure does not necessarily mean more power, because you are increasing the resistance to valve opening.

http://www.airguns.net/general_regulators.php

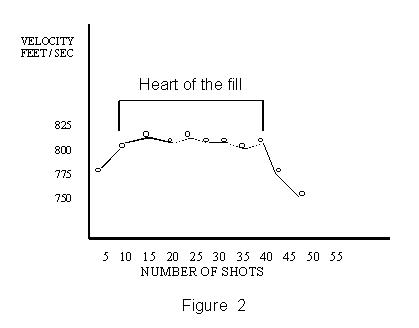

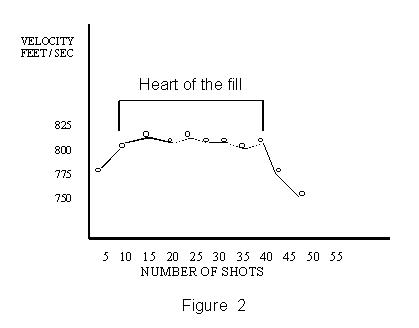

When the gun is cocked the striker is pulled back a certain distance before the trigger sear engages. This distance is called the Stroke. When the trigger is pulled the striker is released and travels forward striking the valve stem of the Firing valve lifting it off its seat allowing air to flow past through the Transfer port and into the barrel. The length of time the valve remains open is referred to as Valve duration and is measured in thousandths of a second. As the reservoir pressure decreases the valve duration increases due to less resistance of air pressure on the firing valve. As the valve duration increases a larger volume of air at a lower pressure is allowed to pass. The result is a rise in pellet velocity. Figure 2 shows the typical velocity verses number of shots curve of a non regulated gun.

Looking at the curve you can see an area where the curve is somewhat consistent. This is called the heart of the fill. Most people will find this area and shoot their gun here for the greatest accuracy. To find this area the gun is filled to full pressure and shot over a chronograph. The shots are counted, velocities recorded and the graph plotted. The pressure at the end of the test is recorded and subtracted from that of the beginning. This number is divided by the number of shots and the result is approximately the amount of pressure per shot that the reservoir diminishes. The gun will now be charged to the pressure where the graph starts to flatten and shot to where the graph starts to drop off.

edit:  20,000 posts

20,000 posts

Posted: Mon Aug 27, 2012 5:31 am

by jmez1996

Ahah congrats on 20,000

Okay if thats the case i think ill still go ahead with my plan unregulated at some point because i like the action they have.

I'll look into the self contained cartridges because that would be sweet if i could somehow make them about the size of a 12gauge shotgun shell.

Also do you think .177 is worth using at 30 yards or is it too light? if so ill consider .22 instead.

Posted: Mon Aug 27, 2012 10:49 am

by jackssmirkingrevenge

jmez1996 wrote:I'll look into the self contained cartridges because that would be sweet if i could somehow make them about the size of a 12gauge shotgun shell.

If you're using high pressure that's a feasible size for the range you want.

Also do you think .177 is worth using at 30 yards or is it too light? if so ill consider .22 instead.

If you can get it to 500-600 feet per second, 0.22 is perfectly fine for 30 yards, and will give you higher muzzle energy for a given air source and barrel length.

Posted: Tue Aug 28, 2012 8:55 pm

by PotatoEnemy17

You should look into a balanced hammer valve, I'm pretty sure someone posted a thread about that a while back. Then performance would not have the "sweet spot" problem. Also it would give you more power.

Posted: Tue Aug 28, 2012 11:00 pm

by Gippeto

Sweet spot is not a problem...you adjust fill pressure to match the high pressure end and refill at the low pressure end. This is just part of tuning.

A 4-5% deviation from peak velocity on either end of the shot string is QUITE acceptable. 10% would be fine on a plinker at 30 yards and could stretch the available shot count considerably.

You can use a program called chairgun to determine velocity required due to range and kill zone size as well as POI rise/drop at target with changes to velocity. Use this information to help plan the max deviation from peak velocity. A handy tool. 8)

Considering the pressure you have available, I would encourage you to step up to .22 cal if you want an effective 30 yard range.

Posted: Wed Aug 29, 2012 2:22 am

by jackssmirkingrevenge

Gippeto wrote:Considering the pressure you have available, I would encourage you to step up to .22 cal if you want an effective 30 yard range.

... or 0.25 if you really want to hammer those targets down, but I think 0.22 is a good compromise between muzzle energy and trajectory.

Posted: Wed Aug 29, 2012 3:03 am

by jmez1996

cheers for the advice.

Does anybody know where pipe/tubing with ID 0.22 (5.59mm) can be sourced? i have had a look online but haven't been able to find anything suitable.

.177 is easy because some a standard gas tubing size is 4.5mm ID

Otherwise i may need to look at another ammunition than air rifle pellets.

I plan on making the valve body from brass and the valve stem and housing and breech block from aluminium.

Posted: Wed Aug 29, 2012 3:06 am

by jackssmirkingrevenge

0.22" is not too easy, however you can "roll down" a 0.22 pellet to fit in a 5mm barrel, or tap it out like so to fit in a 6mm barrel:

http://www.spudfiles.com/forums/adaptin ... t7178.html