I did exactly the same with my first blow-forward boltkustomkb wrote:It sure is! I pulled it apart to look at honing the bores a little and while checking the fits I realized I have made a shock absorber :violent1:

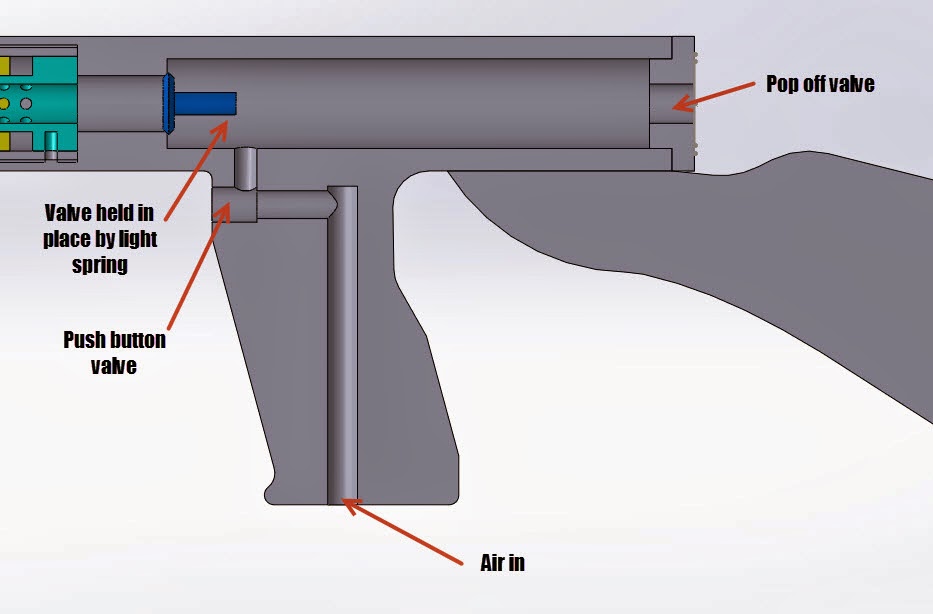

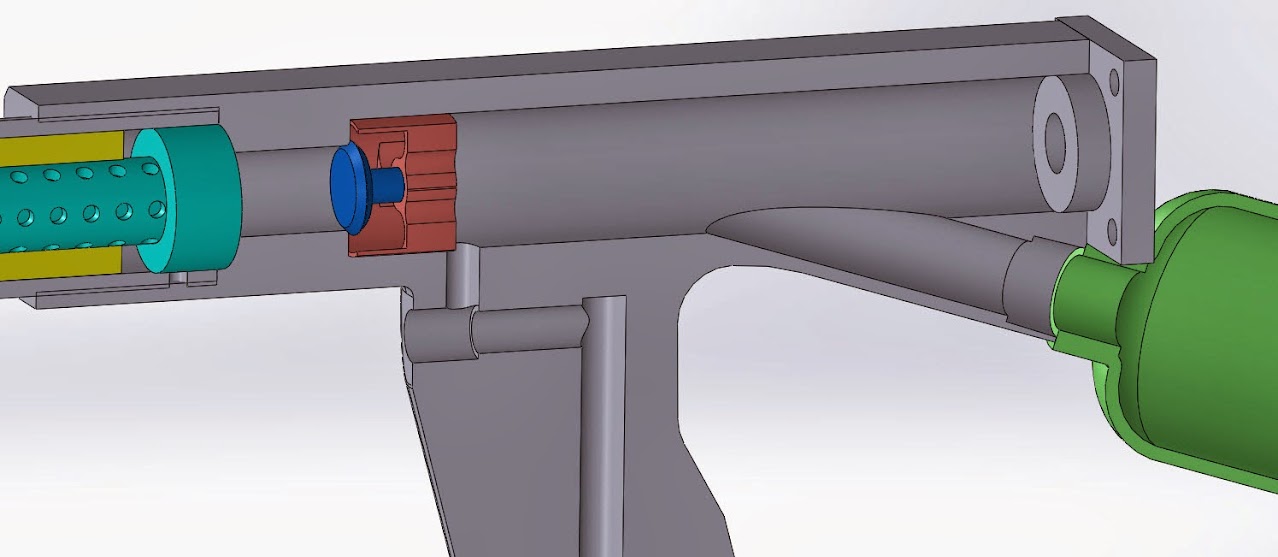

Basically the maroon piston blows back, firing the ball in the barrel (not shown) and then eventually moves back far enough to allow a fresh ball to be loaded into the barrel. As drawn, it would probably jam thoughThanks Poland Spud, for the time to create/ post your design drawing, but I am not sure I follow...

Your machining skills are definitely a saving graceThanks again for everybody's input. I know when a guy shows up, who hasn't paid his dues, and says "Hey everybody, help me design a cannon" it's tough to get behind him. That is why I started to build before asking questions. To show I am serious. I only just found the "useful links and information" post. I feel a bit silly for not reading more before diving in...

.