Page 1 of 2

"The Omega Project" help needed

Posted: Thu Nov 16, 2006 3:14 pm

by PVC Arsenal 17

I decided recently to build a cannon that would finalize all my spudgun projects for a while. Hence "Omega" which often means "end"

I plan for this one to be utterly huge and ridiculously powerful.

I'm going for an over/under 4" tee valve using a 3" cap as a piston.

The chamber will be 4' long and the barrel will be 6' long.

First, I have a few questions:

1-How much travel should the piston have between the plug and the barrel for optimal performance?

2-Does it need have a compression spring so it's always pressing on the barrel?

3-When I make the sealing face and attach a sheet of rubber to the cap using a bolt, how to I eliminate any leaks that might form around the bolt?

4-Where is the proper location for the equilization holes in the piston and how many / how big do I make them?

5-I found a sch 80 plug That I want to use for the back end. Problem is it's $20!! Am I better with just a sch 40 one?

If I think of more I'll post them. Thanks.

Posted: Thu Nov 16, 2006 4:57 pm

by Velocity

1) For performance, it should travel back exactly 1 inch, no more no less. However, increasing this number slightly should yield similar performance, and will insure that the travel isnt less than an inch, in which case you would lose performance.

2) No. My <a href="

http://www.spudfiles.com/forums/viewtop ... icannon</a> (very similar cannon to the one you describe) doesn't use one, and it seals perfectly, every time

3) Tighten the bolt enough; there shouldnt be any leaks. Make sure to put a large (maybe 2") washer on the bolt to prevent the rubber from flipping into the barrel (you will know what I mean if it ever happens to you; easy to fix, but extremely annoying to do after every firing. Plus, it might eventually weaken something)

4) If this is a barrel-sealing valve with no orings, then you need no equalization port. The tiny gap between the piston and the piston seat (I think thats what it is called) should allow air to pass through fine.

5) Go with the SCH 80, especially considering that you are using large diameter, lower pressure pieces. The piece of mind is well worth a couple of bucks

Posted: Thu Nov 16, 2006 5:10 pm

by PVC Arsenal 17

OK thanks... I'll invest the extra $$ for a sch 80 plug. That way when I tap it, It'll go through twice the thickness.

Posted: Thu Nov 16, 2006 5:29 pm

by schmanman

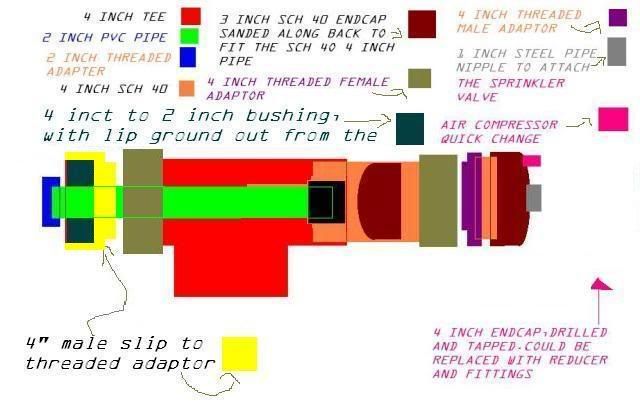

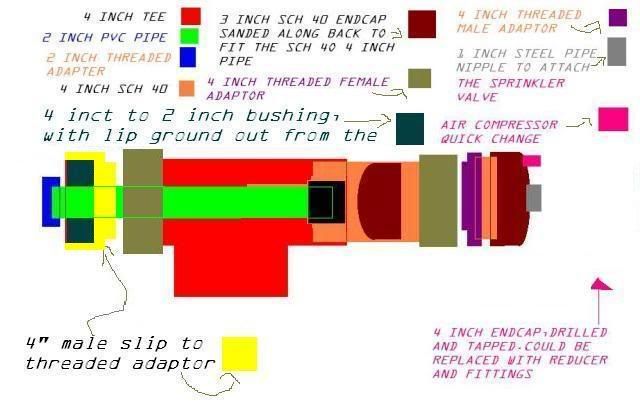

here is the valve I used on the swat gun. very reliable, powerful, and easy to build. buy the tee from <a href="

http://www.sprinkler.com/buy/item/sch40_tees_slip/1953">

here</a> . they are pressure rated (you do not want to use dvw, obvousily). the price is reasonable, so is the shipping. If you order from the web, get it there.

If you have any questions, feel free to pm me.

CLICK TO ENLARGE

Posted: Thu Nov 16, 2006 6:40 pm

by PVC Arsenal 17

yeah, basically how I was gonna do it except with a plug and the male/female reversed on the barrel side from what yours is. Thanks.

Posted: Thu Nov 16, 2006 6:56 pm

by schmanman

no problem. the reason It's threaded on the front is so you unscrew it, and switch between 3 inch and 2 inch porting, and If the rubber coupler splits (It has only once, after probably 3 straight hours of firing, don't ask)

that way you can replace it/ flip it around.

did you check out sprinkler.com?

Posted: Thu Nov 16, 2006 7:06 pm

by SpudStuff

Thier prices are rediculus! I can get them for 1/2 the price they have there! Check ebay, there is a store that sells cheap PVC.

Posted: Thu Nov 16, 2006 7:14 pm

by schmanman

maby a link would help.

(sorry, I couldnt help it, the smilies I found are sweet)

Posted: Thu Nov 16, 2006 8:26 pm

by PVC Arsenal 17

what is the rubber coupling for? Do you use that instead of a sealing face on the piston?

Posted: Thu Nov 16, 2006 8:32 pm

by SpudStuff

Yes it is perfect ruber, nice and soft! Just the way we like it!

Posted: Thu Nov 16, 2006 8:38 pm

by experament_u2

im sorry but i cant help at all i suck so much wih pneumatic i just wanted to say that gun looks very clean and awsome i cant wait to c the real thing anyway good luck with it and dose that mean this will be ur last spudgun

Posted: Thu Nov 16, 2006 8:45 pm

by SpudStuff

You make me sad!

I'll go build a better cannon now.

Posted: Thu Nov 16, 2006 9:19 pm

by MrCrowley

experament_u2 wrote:im sorry but i cant help at all i sucik so much

(at spelling) wih pneumatic i just wanted to say that gun looks very clean and awsome i cant wait to c the real thing anyway good luck with it and dose that mean this will be ur last spudgun

so why the f'k did you post if you can't help?

On-Topic - I say if your going to build a beast like that study Rmich's Amercannon.

Posted: Thu Nov 16, 2006 9:47 pm

by PVC Arsenal 17

Yeah I will. Just using a 4" instead of 6" due to spending limit right now. I'm making the chambers interchangable so enventually I could step it up.

Rmich, I looked at your thread, You used 2 encaps as the piston? Why is that? And they seal against the 4" x 3" bushing? That's what I got from the video.

Did you get that bushing from plumbingsupply?

(And hopefully it won't be my last spudgun. There won't any for a while after till I get money. But it will be the end of the line as far as power and size. I won't go any bigger but instead, focus in MGs and smaller stuff.)

Posted: Thu Nov 16, 2006 9:56 pm

by SpudStuff

No, we mean a piston with the rubber coupling as the sealing face!