Hi,

EDIT: You don't need the spring do you?

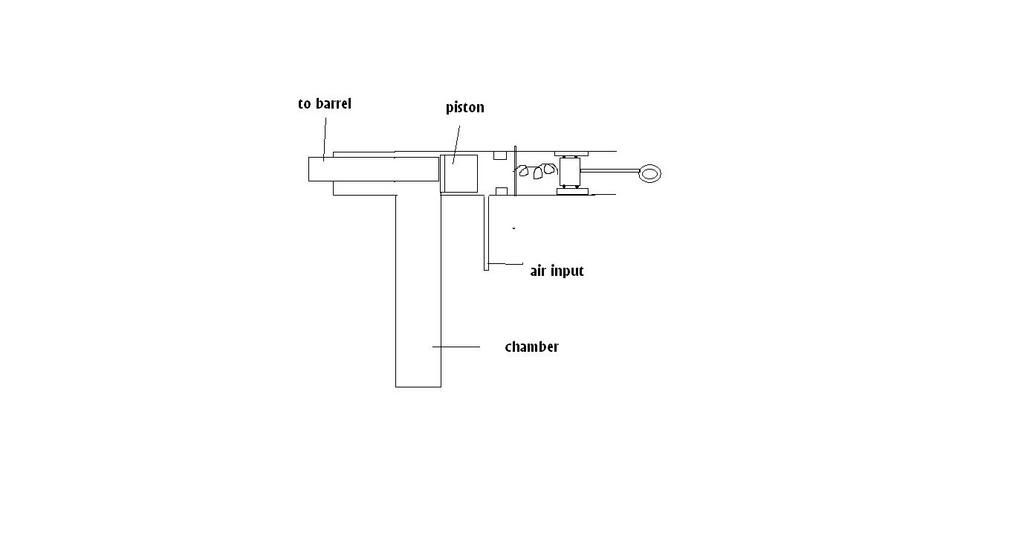

No. It's for luxury only. Auto reset. And for safety: I forgot to add a stop on the drawing to prevent the bolt from going UP. Assume there is one. The spring also helps prevent accidental firing because of - well, whatever could make the bolt creep down.

A second stop to keep the bolt from going too far down - so one can just fire by pulling it a little violently maybe - would also be nice.

Whats to stop the little wire from snapping and the bolt from shooting out towards the user?

What would make it do that? Ah, OK, maybe I see something: Move the red piston seats a little farther out towards the ends of the tee, and move the pistons accordingly.

Thanks noname; so you jam the diaphragm between the tee body and a pipe? Maybe I'm asking silly questions but I have never seen pictures of a home made 'phragm valve, and never tried to make one myself.

This silly little trigger valve was really to have been a miniature DFTV. But I discovered an error in my design, on the train back from my parts supply store*, so I thought up this as an emergency solution instead. But it might end up better than the original plan.

Damn, that has happened many times: I have coffee and do some work or whatever on the way back from where I buy parts - and immediately I think up a much cooler idea for the gun design. Then I am left there with a pile of non refundable o-rings and other stuff for an outdated design revision

*"Koi-Breeder", where I (to their great amusement when I demonstrate the guns,and to their great annoyance when I call them and ask them about the exact inner diameter of a blah blah..). They are not amazed at people who happily pay ~$2000 for one koi, however. A koi is a fish.

Regards

Soren