Page 2 of 3

Posted: Sun Aug 12, 2007 5:08 am

by spud yeti

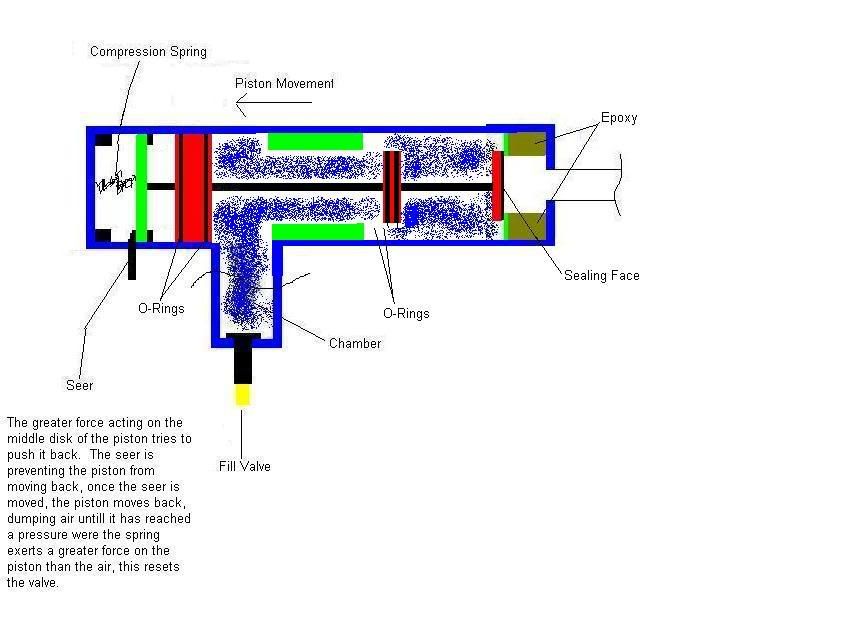

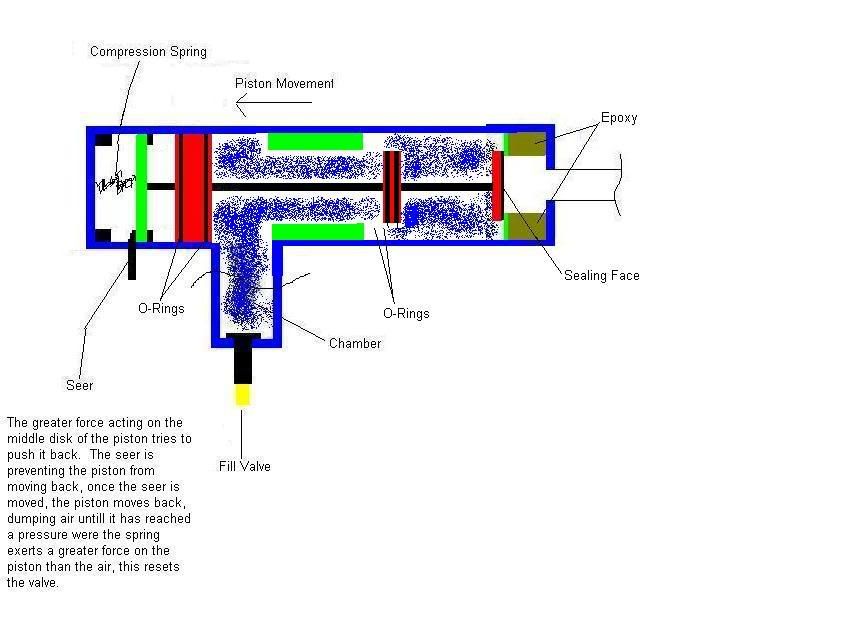

Its a good design, but you have forgotten one vital thing. You have to be able to control the amount of air being released by creating a secondary chamber; because at the moment all your air is going to rush out in one big "oomph". Try creating a secondary chamber, by adding a sealing face that closes the a portion of chamber when the sear is remove and the piston pushed back.

Want a diagram explaination?

Posted: Sun Aug 12, 2007 5:10 am

by Marco321

Thanks for the advice, i forgot about that... Its cool i know what you mean.

Posted: Sun Aug 12, 2007 5:17 am

by spud yeti

Its cool, I often forget about it too when Im designing my valves

Posted: Sun Aug 12, 2007 5:22 am

by Marco321

Yeah. When i make stuff i often forget the most important things lol. But luckily i have a place were people can help me

Reminds me of a story with my ipod...

Posted: Sun Aug 12, 2007 5:25 am

by spud yeti

LOL, enlighten me

Posted: Sun Aug 12, 2007 5:34 am

by Marco321

I had one of those ipod, the first ones to have that click wheel, just before the mini's. The battery died so i decided to buy a replacement of eBay. It came and it came with this special tool to open it, which was of poor quality so i just used a guitar pick. Anyway after fighting the ipod for a while i got the battery in nice and comfortably, managed to put all the wires in gaps so it closed nicely. When i turned it on, it wasn't playing music, so i had to fight it again to open it, i took the battery out to see why it wasn't working, then i saw a ribbon cable wasn't plugged into the headphone jack. After much more fighting the ipod when back together nicely. When i tried to turn it on, for some reason it didn't turn on. I raged at it because of all the time i put into opening it and stuff, so i ripped it open and ripped one of the ribbon cables, i found i had forgot to plug the battery back in...

Posted: Sun Aug 12, 2007 5:42 am

by spud yeti

Ahahahahahaha! LOL, thats hilarious! Sounds just like something I would do too! I usually fix one thing, close it, reaslise I forgot another thing, fix it, in the process forget another thing undone when I close it again; and this continues for ages!

Oh well, back on topic: have you got any ideas to fix your problem?

Posted: Sun Aug 12, 2007 6:05 am

by killagorrila99

jackssmirkingrevenge wrote:My solution (rather predictably

) was ridiculous amounts of epoxy

Yes that was quite predictable. Nice design, Though you would have alot of back pressure problems if the o-rings didn't seal perfectly. And Jack, Ever think of making a whole gun out of moulded epoxy? Valve, fittings and all?

Posted: Sun Aug 12, 2007 6:22 am

by us sniper

Marco, why don't you place the sear behind the red block. That way the pressurized air forces the red block backwards, it hits the green, an the entire piston is pushed backwards. The only change to make that work would to be to add an additional spring behind the red block, but it would have to be really weak. Other than that I think your design would work fine. I am also design something that uses the same principle except is is inline.

http://s153.photobucket.com/albums/s240 ... cValve.jpg

Posted: Sun Aug 12, 2007 7:19 am

by Skywalker

Marco, good work! That first design is basically a chamber-sealer, is it not? I think your second design there has some promise, but I'm doubtfull that it will work semi-auto. maybe it will, though. Prove me wrong!

@Jack: interesting design there. I'd thought of something like that, but what exactly is the advantage over the traditional barrel-sealer? B/c it looks like that would be extra work for not much benefit that I can see.

Posted: Sun Aug 12, 2007 10:14 am

by spud yeti

@Jack: interesting design there. I'd thought of something like that, but what exactly is the advantage over the traditional barrel-sealer? B/c it looks like that would be extra work for not much benefit that I can see.

There is much less pilot volume, more compact and just a new way I guess

but I'm doubtfull that it will work semi-auto. maybe it will, though. Prove me wrong!

Trust me, youre going to be proved wrong, the flaw is being fixed as we speak

Posted: Sun Aug 12, 2007 11:15 am

by Skywalker

Hmm. Somehow I missed reading this whole second page of discussion b4 I posted. Oops!

So the flaw is that as it stands, once the piston opens the barrel, you don't have any of that suction force on the front piston, so it's going to be hard to get it to close. You have to overcome the force against that rear piston somehow. That's why I was saying that the whole notion of a barrel-sealer is optimized for quick opening, but that makes it bad for closing, reseating, and therefore semi/auto operation.

And you are going to fix it by, what, reinventing Clide's GB semi? Or do you have something else up your sleeve?

Posted: Sun Aug 12, 2007 11:55 pm

by Marco321

I have something up me sleeve, ill post it when i am happy with the design. Spud yeti has helped me alot with the design over PM.

Ill post the finished design hopefully in the next 2-3 days

Posted: Mon Aug 13, 2007 12:24 am

by spud yeti

I have something up me sleeve

We all do: an arm!

Posted: Mon Aug 13, 2007 12:29 am

by Marco321

spud yeti wrote:I have something up me sleeve

We all do: an arm!

Thats strange, i don't have one of them...

but seriously... here is something i came up with. It works in a similar way to clides GB semi.