Page 1 of 2

Auto diaphragm testing

Posted: Thu Aug 09, 2007 9:55 pm

by Skywalker

I've got a small prototype coax pneumatic, with a union-based diaphragm. The barrel is 1/4" brakeline, so pretty small compared to the 3/4" union. What I've found is that if I can precisely control the air leak rate out of the schrader, I can make the gun fire auto. Generally, I get a series of about 6 or 7 pops, maybe more, in the space of a second or so. It's hard to tell exactly, because they all run together into a sort of muffled fart by the end.

My theory is, when the 'phragm unseats and the gun 'fires,' the chamber pressure drops below the pilot pressure, so the diamphragm slaps shut. Meanwhile, the air continues to leak from the pilot out the schrader (and probably through the equalization hole too, but that can be ignored I think) until the pilot pressure is again low enough (relative to the new, lower chamber pressure) to fire again.

The pressure drop of the chamber per shot is determined by the pressure drop of the pilot each shot, more ore less, which is determined by how much pressure differential it takes to fire the gun. That is largely determined by the area ratio between the 'phragm or piston, and the barrel. (But it also depends strongly on the chamber pressure; the drop per shot is proportional to the chamber psi.) The bigger the phragm/piston, the less pressure you let out before the gun fires, so the less pressure is lost by the chamber before the thing seats again.

The firing rate is determined by the leak rate out the schrader, along with any leakage around the diaphragm or piston. So the ROF should be adjustable, but it looks like the number of shots per tank is determined by the starting pressure and the phragm/barrel ratio, which is fixed when the gun is built.

Anyway, the result is that you can make a stand-alone automatic bb gun with a rep-rate of just a handful of rounds per second, using probably a paddle/interuptor style loading mech (which, unfortunately, I can't put on my prototype b/c it's a coax.) The best thing about it is that it's dead simple; the worst thing is that you can't adjust the number/power of shots per tankfull of air.

Posted: Thu Aug 09, 2007 10:13 pm

by Atlantis

The problem with this is that the pressure drops very time you fire it. What did you use for a diaphraghm?

Posted: Thu Aug 09, 2007 10:45 pm

by VH_man

replace the schrader with a needle valve and experiment. you might be onto something

Posted: Fri Aug 10, 2007 7:19 am

by Skywalker

Atlantis: you can't help the pressure dropping! If you let air out of the chamber, down the barrel, the chamber pressure is going to drop. (Of course, if you have the chamber hooked to a regulated HPA bottle or compressor or something, it'll go back up afterwards, which might prove interesting.) The problem is, you are going to get a very strong dependence of shot power on chamber pressure (which is going to drop), and since the only other factor is the valve size, you can't adjust for that in any way. The only way to get around it and end up with something like consistent shots is to have an enormous diaphragm compared to the barrel. I'm thinking that a 1-1/2" or 2" union might be needed just for a 1/4" barrel like mine.

VH_man: I don't have a needle valve. What I'm doing is using a screw with a nut on it as a gauge of sorts. By running the nut up and down, I can adjust how far the screw can poke the schrader open (the nut hits the rim of the schrader and acts as a stop).

I've gotten the thing to cycle on the order of 2 RPS, maybe, which is slow enough to make semi-auto operation possible as well.

*****************************************************

Technical details here:

The amount of 'suction' force on the diaphragm caused by the barrel when the valve is shut is proportional to the area of the barrel and the pressure difference bewteen the atm. and the pilot area, which is the same as the chamber pressure at that time. So force(suction) =area(barrel)*psi(chamber). The amount of force on the diaphragm that pulls it open when firing is proportional to the area of the 'phragm, minus the area of the barrel, times the pressure drop from the chamber to the pilot. force(opening)=area(phragm)*psi(drop-pilot).

Rearranging and combining, we get psi(drop-pilot)=force(opening)/area(phragm) and since force(opening) must be equal to or greater than force(suction) we can write: psi(drop-pilot)=area(barrel)*psi(chamber)/area(phragm).

When the valve needs to shut, the chamber pressure has to drop somewhat lower than the pilot pressure so that the air force on the diaphragm pushes it towards the barrel. This means that the pressure drop per shot is somewhat more than the pressure drop required in the pilot to fire the valve. Looking back, the pilot pressure drop is determined by the the ratio of area(barrel)/area(phragm) times psi(chamber).

Basically, the chamber pressure drop per shot is a constant fraction of the current chamber pressure (for my gun, maybe ~10-20%). Thus the drop/shot is going to go down each shot, and so is the pressure. So the amount of air released and the air pressure are going to go down, basically in a decreasing exponential curve. Thus the power per shot is going to drop very dramatically. Adding a larger chamber doesn't change anything: it only means your valve will drop that whole chamber the same amount, which means more air released, probably much more than you need for each shot. (Unless of course you had a Vogt feed, in which case you'd get multiple rounds per burst of air. That could be interesting.)

The only remedy is to make the pressure drop a smaller fraction of the chamber pressure, and to do that, you have to change the ratio area(barrel)/area(phragm). You need to make the phragm very large, and the barrel very small. In fact, it might be adviseable to make the valve seat smaller than the barrel. Using 1/2 the diameter there would cut the psi drop by a factor of 4, perhaps without too much loss of power.

Posted: Fri Aug 10, 2007 7:46 am

by spud yeti

Holy crap that last post was long, so I didnt read it

But from your first post that sounds like a really good concept you could play around with. What you coul do for constant pressure is have a double input: one one the chamber and one in the pilot; so the diaphragm is pushed foward, but pressure doesnt decrease went firing starts. You'd just need a slight delay on the chamber side for the diaphragm to push forward first. Or you just have two different pressures, the higher being on the pilot side.

Posted: Fri Aug 10, 2007 7:51 am

by Hotwired

Someones getting pretty dam close to the semi-auto method I discovered a few months ago 8)

Posted: Fri Aug 10, 2007 8:15 am

by spud yeti

Have you built a gun around the method yet, hotwired?

Posted: Fri Aug 10, 2007 8:16 am

by Skywalker

@SpudYeti: yeah, I got carried away, lol. I have a hard time not gushing all the crazy stuff that runs through my head.

Hmm, you gave me a crazy idea, though: what if, instead of triggering the gun by dropping the pilot pressure, you fired it by raising the chamber pressure? Is that what you were getting at? Oh boy, this could be interesting.

@Hotwired: heh, believe it or not, I came across your concept a while ago. I like it, but that pricey valve put me off too. I've been scheming a cheap way to build it, but I don't quite have the mechanical skills to do it. But if you are curious, I will just say that all it requires is a single sliding o-ring seal and a schrader valve.

But instead of that, I was thinking about just using a hammer to hit a schrader valve to get a metered-out pilot pressure drop. That's why I built this gun. But then I discovered this auto business, which beats semi-auto, if I have a good simple reloading mech.

Posted: Fri Aug 10, 2007 8:22 am

by spud yeti

skywalker wrote:@SpudYeti: yeah, I got carried away, lol. I have a hard time not gushing all the crazy stuff that runs through my head.

Hmm, you gave me a crazy idea, though: what if, instead of triggering the gun by dropping the pilot pressure, you fired it by raising the chamber pressure? Is that what you were getting at? Oh boy, this could be interesting.

Yeah, pretty much so, except mine was to do both the pilot and increase pressure; but your idea is more efficient/just better

I also have the problem of knowing when to stop, luckily my typing abilities (or lack thereof) help me with it

Posted: Fri Aug 10, 2007 8:26 am

by Hotwired

Ah you must have seen the original concepts. The last time I updated it it was using a slide valve which is about 1/3 or less the price which is fairly affordable.

Think I might make a proper topic of the valve system over here as I'm not going to get my semi-auto cannon done anytime soon.

Posted: Fri Aug 10, 2007 8:30 am

by spud yeti

That would be a good idea. I would be happy to see yours, because I have designed, and I am now building a semi-auto paintball gun (47% complete) so Im intrigued by semi-autos. (Its also copper, yay for copper guns 8) )

Posted: Fri Aug 10, 2007 10:16 am

by jimmy101

Very clever use of the schrader.

I wonder if you could replace the schrader vent with a pressure regulator (high pressure side to the chamber) or a pop-off valve? Of course this moves the gun's cycle control from the diaphram to the regulator or pop-off.

An easy way to measure the RPM for your gun is to just record the sound of it firing (a laptop with a MIC works great) then look at the waveform in an audio application like

AudioEdit

Posted: Fri Aug 10, 2007 10:27 am

by spud yeti

But if you use the method of controlling pressure from the chamber side, it would be pointless to even have a valve on the pilot side. It all depends on what he wants to do. Doesnt he want the air to be released slowly from the pilot area though?

An easy way to measure the RPM for your gun is to just record the sound of it firing (a laptop with a MIC works great) then look at the waveform in an audio application like AudioEdit

Or you could just shoot for say 10 seconds and count the rounds shot. Or put in 50 rounds and see how long it takes to shoot them all, and divide the time taken by 50. Or get midgets in jock-straps to count really fast

Posted: Fri Aug 10, 2007 12:27 pm

by Skywalker

@hotwired: I think I saw the slider valve part, but doesn't that vent to the atm, so you have to find some other way to cycle the reload? I bet people would like to see your design.

@jimmy: thanks! I'm still thinking about how to go from here, so all ideas are appreciated. You are right, though, that adding a pop-off would change the concept to one that has been used before, though succesfully. I'm not too intent on measuring the RPS, it's pretty simple to adjust the rate with the schrader, although there's probably an upper and lower limit.

@yeti: I am not sure what I want to do! What I have right now, though, is that the air is released slowly from the pilot side, but the problem is that in order to reseat the valve, the chamber pressure has to drop a bunch. (But this problem is also going to crop up for any gun with a reseating piston/phragm using only one main chamber, no matter how you pilot it.)

I started out thinking I didn't want to have a seperate pressure supply (compressor, HPA, Co2, backpack tank, FE, etc), but having one might make some interesting alternatives possible. I just want to explore right now.

Posted: Fri Aug 10, 2007 12:37 pm

by spud yeti

Yeah, I think the best thing to do is just sit and think about it, and the idea always evolves and transforms. We (the forum) just aid you in your thought process

I would go for a seperate air input, its just so handy!

EDIT:

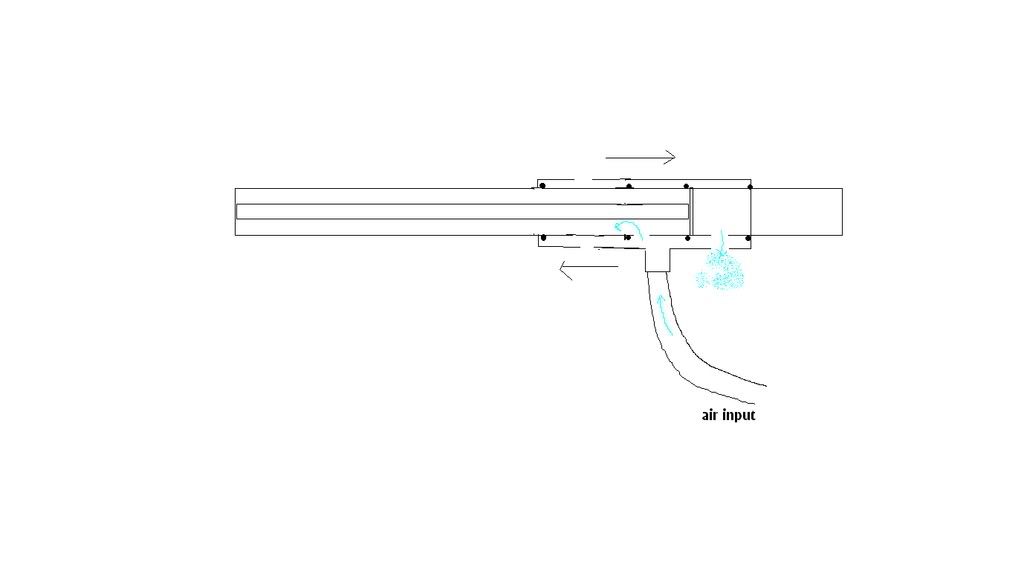

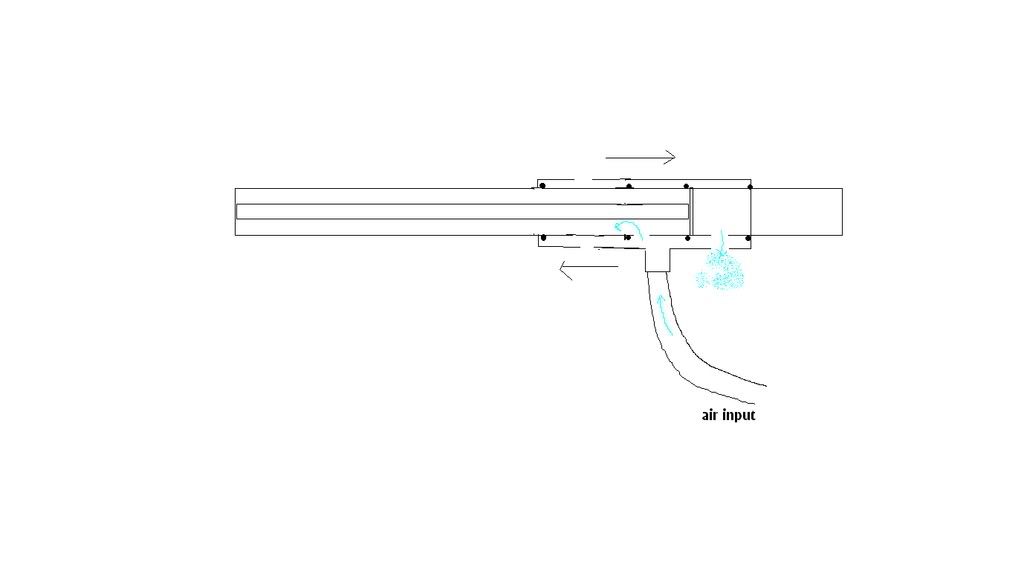

OK, my mind just created a miracle. I have been thinking about your concept most of the day, and suddenly this idea popped into my head:

Sorry about the bad pic, but I drew it fast before I forgot it!

It like a pump action. As you slide it in one direction, it fills the one side, whilst the other side lets a small amount of air off due to a pin-hole sized hole; then vice-versa. This is more a semi-auto concept, but I really like it

. I think I'm going to make a gun around it now

Here is a diagram: