Page 3 of 3

Posted: Tue May 31, 2011 11:44 am

by Labtecpower

extremely nice !

I'm looking forward to see the damage to aluminium.

Do you have a diagram that shows the construction ? I would like to take a look at it.

Posted: Tue May 31, 2011 10:16 pm

by mobile chernobyl

I've been looking into the feasibility of these guns and I found patents #'s 5,052,272 and 5,789,696 to be of the most use. They're pulling close to 40% efficiency - from your first few posts I gathered something between 10 and 20% depending on the test? I know their methods aren't going to be the easiest to replicate but it's something to chew on

You've probably seen these though lol... just putting it out there for those that want to learn more about this type of ETCG/LGG combination and the iterations it's been through.

Also filed by GT Devices (now owned by General Dynamics) is an earlier method yet under patent # 5,012,719. This design is pretty interesting and dabbles with H202 and a more elaborate chamber design, but in the end suffers from lower efficiency's by not taking advantage of the finely suspended aluminum particles (micron level) like that of the other two patents assigned by the Navy.

Posted: Tue May 31, 2011 11:52 pm

by DYI

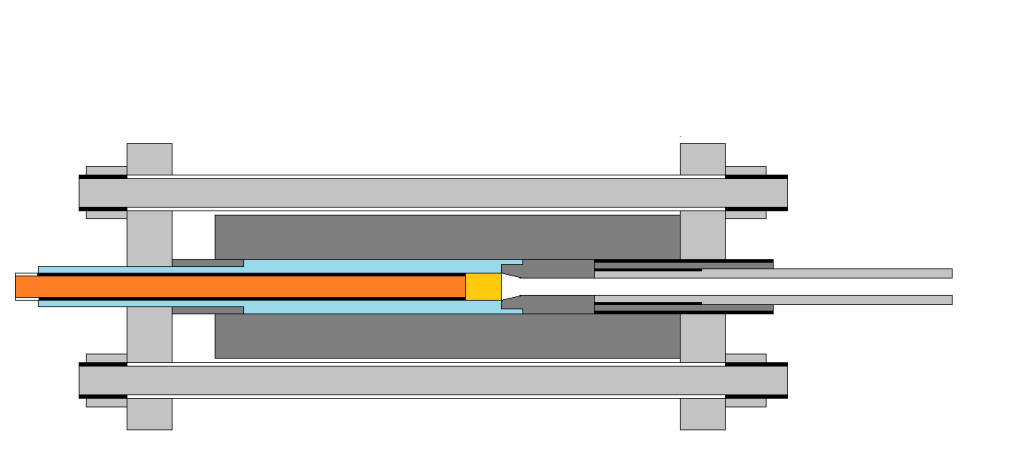

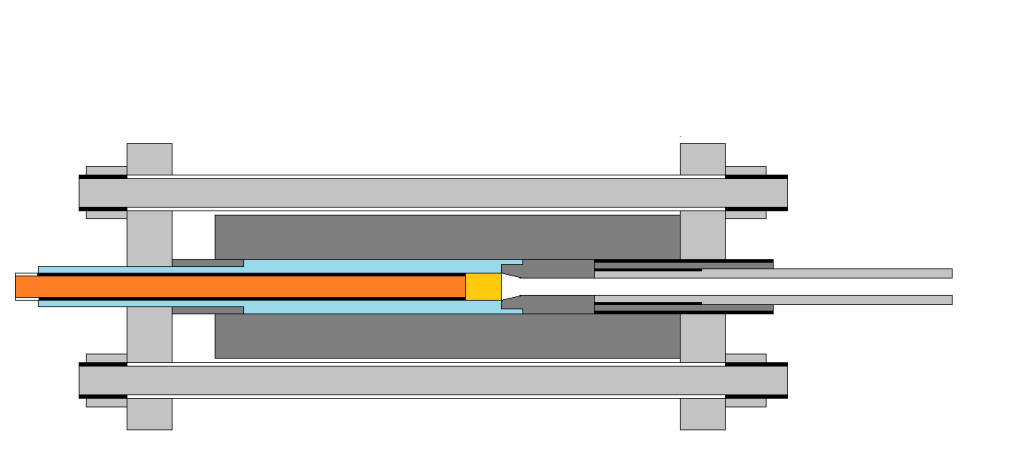

Here's the diagram. Dark grey is normalized 4340 / B7 all thread. Lighter greys are annealed 8620, 1018 plates, and hardware store all thread (so is orange, in this case) and black represents thread engagement.

I'm always kind of wary of patents, but 5789696 is a good intro to the topic. 40% seems a little optimistic, except possibly at very low speeds. The insulators are done, and I hope to do the shot with the aluminum target tomorrow. Also on the agenda are some shots with steel rounds and experimentation with rupture diaphragms.

Posted: Wed Jun 01, 2011 6:47 am

by inonickname

Wait a minute, it survived a shot?

That's something new for you

Posted: Thu Jun 02, 2011 8:21 pm

by DYI

Wait a minute, it survived a shot?

That's something new for you

I'll have you know it has now survived TWO shots, you bastard

The shot against the 1/8" aluminum target (launching a 0.12g airsoft round) was actually done yesterday. Owing to the presence of large amounts of unburnt fuel in the first shot, I adjusted the fuel content to 0.7g of Al/H<sub>2</sub>O mix (the input energy was also increased marginally, to 6kJ at 15.7kV) for this one. As the reaction releases 7.8kJ/g, this nearly matches the reaction energy to the electrical input. The water content was 0.87g for a 150% excess. The report was noticeably louder than that of the first shot, and a flash was visible through the containment vessel.

Opening the container post-shot seemed to confirm that first impression of a more energetic shot, and the visible unburnt fuel amounted to a few flakes with a total mass of less than a milligram. A steel plate with a layer of paper taped over it was placed behind the aluminum to catch any fragments that would otherwise pass unrecorded into the walls of the container. It appears that a more substantial backstop was in order, as a few fragments made it through the aluminum and shredded the paper behind it. 30% of the round's mass was recovered, the balance of it in a single blob of plastic which must have composed the section of the round farthest from the impact point. It looks like the middle fragmented heavily on impact, and the nose probably boiled away.

A record has been kept of the dimensions of all parts (except the insulator, which is destroyed by the process of removing it from the casing), showing minor deformation on the most heavily stressed parts, likely indicating peak pressures of over 100kpsi. Some leakage appears to have occurred on this shot from the interface between the insulator and the breech, but it was not significant, and the all-important casing section is holding up nicely.

Finally, the pictures. I think you'll quite enjoy them.

Pre-shot:

Post-shot:

Penetration

Closeup of impact site

Comparison (entry hole diameter is .38", from a .24" round)

Posted: Fri Jun 03, 2011 12:13 pm

by Labtecpower

Posted: Fri Jun 03, 2011 9:20 pm

by DYI

Just did the final shot of the week, a 0.12g airsoft round at 6kJ input with 0.65g fuel mix (and the remaining volume filled with water, as usual). The target was a 1/4" steel plate (from Lowes, indeterminate alloy, likely low quality and probably annealed). At three times the density and twice the thickness of the previous target, I was always reasonably certain this would stop the round. There is, however, now a rough 1mm deep dent in the plate, 7mm across, with the beginnings or a crater rim around the edge. While looking for the remains of the round, I found this:

Doesn't look like much, I know, but that's spalling off the back of the plate that has embedded itself in the wood behind it

Also, no lead pellets. I'm not hobbling this purpose built high velocity gun with overly heavy slugs

Posted: Sat Jun 04, 2011 6:07 am

by Zeus

Now this may be bordering on the kind of discussion not allowed here, but thinking about Al powder and water got me to thinking about instead of using water, using hydrogen peroxide.

Peroxide watergels are woeful energetics (compared to others), but it may provide a slight increase in velocity.

I "think" it would decrease the amount of unused Al powder ejected from the launcher, which might increase efficiency to some degree.

Posted: Sat Jun 04, 2011 7:13 am

by DYI

Zeus, that would give us a higher ratio of aluminum oxide to hydrogen in the propellant gas. It would likely decrease performance significantly. When running 8.5kJ/g electric input the mix burns just fine with an airsoft round, and with heavier rounds, as confirmed on the reading week break, 6kJ/g burns just fine at lower launch speeds.

Also, it should be abundantly clear to you why I cannot use hydrogen peroxide now, or in the near future.

Posted: Sat Jun 04, 2011 7:28 am

by Crna Legija

Could you do a shot with no round, so we can see what damage the propellant blast can to the same aluminium you shot before.

Posted: Sat Jun 04, 2011 11:54 am

by Fnord

Figured I'd delay my comment until I had something useful to add...

Here is an idea I came up with during a boredom session at work. I'm not sure if it presents any advantages in terms of reliability, but it may eliminate all switching losses and remove the presence of aluminum oxide.

Let me clarify; this is an example diagram, not a finished product. Mechanical issues have not been thought through heavily.

The principle is to use a light gas like hydrogen or helium at extreme pressures to create an insulating boundary where the electrode extends into the chamber, eliminating the need for a mechanical switch.

When the appropriate pressure has been reached, the capacitor bank can be charged. After this has been accomplished, the pressure is raised again until the burst disk ruptures, allowing the gas to evacuate itself from the barrel. The projectile is slightly oversized for the barrel and detent, and thus is unaffected by the pressure drop.

As you will note in the diagram detail, the detent ring allows gas to leak past the projectile slowly because of the imperfect seal. When the gas pressure drops sufficiently, the dielectric breakdown strength will be exceeded and the capacitor bank will discharge through the remaining gas. As the projectile moves forward, the detent leak will be bypassed and the seal will be perfect again.

Notes:

-In practice this should all happen quite quickly due to the low volumes involved.

-There is no traditional "working fluid" or chemical reaction in this design, although it could be adapted to make use of one.

Oh and DYI, nice pictures. I think I quite enjoyed them

Posted: Sun Jun 05, 2011 3:51 am

by Zeus

Perhaps I wasn't clear in my post, I'm used to the "zero oxygen balance means higher efficiency" thinking, as opposed to the principles in ETG discussion.

I wasn't suggesting for you to use hydrogen peroxide either, it was purely postulation.

On another note, I should get a small lead disc well beyond the speed of sound in STP in the coming days, need I say more.

Posted: Sun Jun 05, 2011 4:44 am

by inonickname

Well, if your magical construction is up for another shot...

Another coin?