This is the record of my electric gun experimentation for summer 2011. I'll gloss over the basic principles of the launcher's operation in here, but it's covered pretty well in this thread. Feel free to ask if you have any questions that aren't covered in there. Lack of time and funds, and a few minor design problems meant that I didn't get quite as much done as I'd have liked to. The following is what you'll find in this first post, subject to possible future updates:

-technical specifications of the design

-description of working principles of the launcher

-diagram of design

-pictures of completed launcher and test setup

-pictures of projectiles and targets

-video clips of tests

Bore: 1/4"

Barrel length: 8.10" (20.6cm)

Chamber volume: 0.90cm<sup>3</sup> or 1.5cm<sup>3</sup>

Chamber diameter: 7/16"

Casing outer diameter: 2"

Overall length: 37.5cm

Fuel quantity: between 0.65g and 1.2g

Electrical energy input: 5.8kJ - 14kJ

Capacitor charge voltage: between 15.5kV and 24kV

Performance: Muzzle energy between 1kJ and 3kJ, depending on configuration. Capable of muzzle speeds over 3000m/s.

Design pressure: 100kpsi (heavy casing provides inertial confinement, allowing higher pressures in practice)

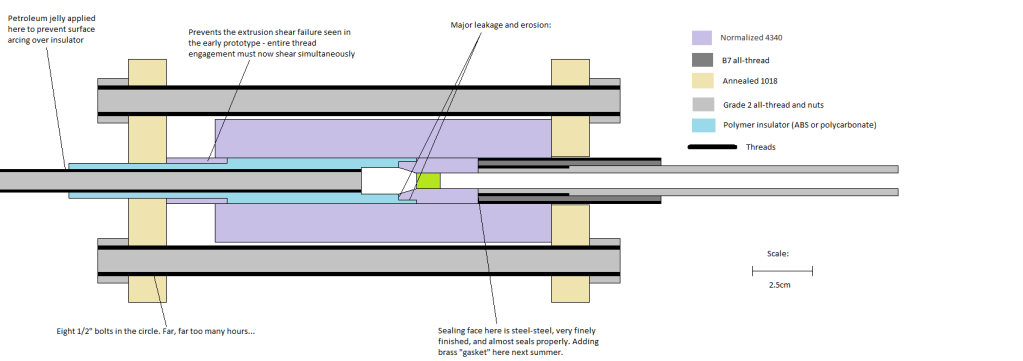

Breech, retaining ring for insulator, and casing are all normalized 4340 steel, nominal yield strength of 125000 psi (860MPa)

All credit for the unit system employed above goes to the Canadian government

Diagram of internals:

The combustion reaction in question is:

4Al + 6H<sub>2</sub>O --> 2Al<sub>2</sub>O<sub>3</sub> + 6H<sub>2</sub>

For a stoichiometric mix, this works out to a 1:1 mixture by mass, with a density of 1.85g/cm<sup>3</sup> and an energy content of 7.8kJ/g. In the case of this launcher, the mixture used is, by mass, 5:11 (aluminum:water). Stoichiometric mixes caused incomplete combustion at lower energy inputs, and there was not sufficient time to test them fully at higher energy inputs.

Despite being very energetically favorable, this reaction is very difficult to initiate, due to the passive oxide layer which is always present on aluminum in contact with oxygen. The solution is, in this case, to boil and partially ionize it by passing an electric current through flakes of aluminum (roughly 10μm x 500μm x 500μm for this launcher) suspended in water. The current pulse is just under 40μs in duration and had a maximum magnitude between 50kA and 90kA, depending on the desired energy input. This current flow and boiling process is extremely violent and induces essentially instant mixing and combustion, converting a room temperature fluid-solid slurry into a 6000K plasma, which is then used as the propellant gas in the same manner as in a conventional combustion gun. Pressure generated is confirmed to be in excess of 700MPa (100kpsi or 6800 bar), and the performance with lightweight rounds appears to indicate that the hydrogen:metal oxide ratio at the projectile base increases dramatically during the shot, making the effective sound speed much higher than would be expected.

Regrettably, no direct measurement of performance was possible this summer (we're working on it though, and it should be ready for next time around). This propulsion method, while capable of high speeds, is by its nature rather inefficient at all but *very* low speeds (all that hot aluminum oxide is essentially wasted energy). Lack of available energy limited the performance achieved, and it may not be possible to properly test the very high speed end of things with my current capacitor bank (although I could, in theory, increase the current pulse to 24kJ, the capacitors' operational lifespans would likely be measured in tens of shots).

Hello, everyone who skipped the above summary. Enjoy the nice pictures, but please don't post asking how I meetrd teh feul...

Assembled front view:

In firing position, rear view:

Chamber side of breech:

Barrel side of breech:

Assembled barrel (the threaded section is a 3/4"-16 B7 threaded rod). Two impact marks are visible here: the large yellow one is from a brass ball at 16kJ chamber energy, the small circle is spalling from an airsoft round hitting the other side of the plate (at 11.5kJ chamber energy). Higher velocity capabilities can be achieved by increasing the ratio of the electric pulse energy to the chamber chemical energy.

Close-up of the brass ball impact:

And a different angle:

Back of the plate:

Airsoft round vs. 1/8" aluminum flat at 11.5kJ chamber energy (two other angles of this on my Photobucket account):

Close-up of steel bearing ball shattered after impacting a 3/8" steel plate:

Aluminum ball vs. 1/4" steel plate at 10kJ current pulse, 6kJ chemical energy (this was over two metres from the muzzle - those rays extending out from the crater are from the impact alone):

Reverse side of plate, same impact as above:

0.77g aluminum slug vs. 1/4" steel plate. 12kJ current pulse, 10kJ chemical energy. Before:

After:

Aluminum spatter on steel profile supporting target:

And finally, one for Jack: 3g brass slug vs. 1/4" plate:

And the back:

Here's a short video compilation. Not all the shots were recorded on high speed, and not all the attempts at high speed recording worked out, so it's a short video...

Planned improvements:

The worst leaks occurred at the chamber-breech section. These should be remedied by modifying the sealing face so that the insulator fits inside the breech, rather than the other way around (this causes the insulator to expand under pressure and seal against the breech, a scheme that worked very well in the old ETA). Another seal that leaked somewhat was the breech-barrel interface. This is also easily remedied by adding a small brass gasket (more like a very short tube) which seals in the same way as mentioned for the insulator (this is how firearm cartridges work, and with close tolerances they are reusable for many shots).

The bolted connections may be replaced with threads after I get the tooling needed for that modification, and the thread engagement on the insulator may be increased for very high pressure shots (small chamber volume, high electric discharge energy). Also in the works is a smoothbore barrel to replace the current "roughbore" version

This post is not complete - there's a good deal of relevant information that just didn't make the cut to get into this summary. Feel free to ask questions, and I'll do my best to answer them. Ideas for improvement are, as always, greatly appreciated.

* Unless you're a master of the "advanced science", and the sort of genius who can figure out how to make a combustion gun that runs on GASOLINE. In that case, I bow before your vast intellect, and beg you to devote your mighty powers of invention to justice and peace