Page 2 of 3

Posted: Sat Apr 16, 2011 10:23 am

by Major Collins

Ahh good point

mark.f wrote:You don't get zapped every time you touch a bolt in your car while the engine is running, do you?

no.... but i create too much static and shock myself on the way out of the car everytime haha

Posted: Sat Apr 16, 2011 10:24 am

by Crna Legija

i used ptfe tape and it insulated the spark plug from chamber wall, just be sure to use more than normal.

Posted: Sat Apr 16, 2011 10:35 am

by Technician1002

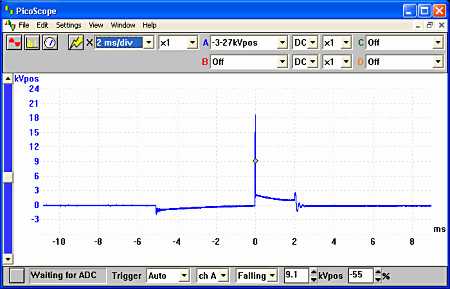

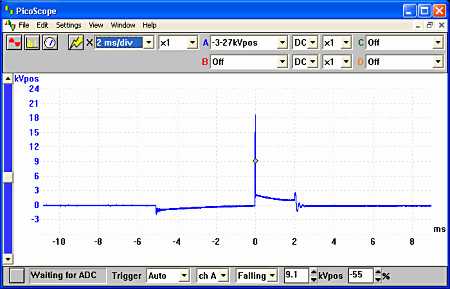

The business end of a typical spark plug is like this.

The voltage on a plug reflects some of the activity of the current in the primary. There is a small step in voltage as the points close and coil current builds. This dwell time is relatively short. The points then open and the rapid halting of the current creates a high voltage in the primary of about 300 volts and about 20 KV in the secondary which causes the plug to fire. The polarity is typically a positive spike to minimize the tip erosion. Either polarity can be used to make a spark.

For a full breakdown of the waveform, the flat line at the very beginning, nothing is happening. At about 5.5 ms before the spark, the points close. The current builds in the coil primary up to the time the points open at time 0 on the line. At this time there is a very rapid rise in voltage until the spark plug fires. The plug firing shorts out the coil and the voltage rapidly drops to a lit arc period of time. As the coil current drop and the arc becomes hot, the voltage drops for another 2 ms. Yes the plug is lit for a full 2 ms in this waveform. When the voltage and current is too low to maintain the lit arc, it goes out. This sudden break in current results in a small second spike in voltage. The coil and cap (condensor) resonate resulting in a ringing waveform which quickly dies out. The circuit is then idle again until the process repeats for the next shot.

Posted: Sat Apr 16, 2011 10:43 am

by Major Collins

Crna Legija wrote:i used ptfe tape and it insulated the spark plug from chamber wall, just be sure to use more than normal.

i like it, i will be sure to try this

Posted: Sat Apr 16, 2011 11:32 am

by Major Collins

i threw some ideas together and i came up with this

the olives will be soldered to the copper pipe

what do you guys think?

btw i know i draw like a five year old hehe

Posted: Sat Apr 16, 2011 11:37 am

by mark.f

Uh, I don't think you quite understand what an olive is/does.

An olive is tapered at two ends and has a hole that tubing slides through. When clamped in a compression nut, the tapered ends seal inside the compression fitting and the interior walls seal around the tubing.

There is no adapter to my knowledge which solders inside of copper pipe.

Posted: Sat Apr 16, 2011 11:50 am

by Labtecpower

comment not needed

Posted: Sat Apr 16, 2011 11:51 am

by Major Collins

mark.f wrote:Uh, I don't think you quite understand what an olive is/does.

An olive is tapered at two ends and has a hole that tubing slides through. When clamped in a compression nut, the tapered ends seal inside the compression fitting and the interior walls seal around the tubing.

There is no adapter to my knowledge which solders inside of copper pipe.

i do know what they are , and not necessary i have brass ones that are tapered to one side only and come with different compression nuts

picture of compression nut i was on about

http://shedowe.en.made-in-china.com/pro ... -C04-.html

compression nut i meant yet i have a bad habbit of calling them olives

its the compression nut that fits into the tubing and i will solder the two together and the solder will run between the two and seal tightly ,i have done it before

btw i forgot to add a shrader ,that would go anywhere on the copper tube

but back to the picture do you think it would work?

Posted: Sat Apr 16, 2011 12:34 pm

by HarriDawwg

Hey i new but was just wondering why bother with the sparkplug?

I mean why not just have the two wires from the BBQ igniter going straight into you chamber, Attach them to screws and screw them in or if your chamber is metal attach a wire to the outside and pull one though so the spark jumps from the wire straight to the inside of the chamber wall?

the only problem is you cant touch the chamber because you will get shocked unless you wrap the chamber/whole gun in a non-conductive material.

Posted: Sat Apr 16, 2011 1:07 pm

by Labtecpower

We're discussing hybrids here. The sparker needs to be airtight, and a sparkplug is a pretty logical option.

Posted: Sun Apr 17, 2011 12:43 am

by Insomniac

Not only that, but even if your chamber is uninsulated, and serving as one electrode, you still won't get shocked. You've gotta have two points of contact to get a shot.

Posted: Sun Apr 17, 2011 12:59 am

by Major Collins

Insomniac wrote:Not only that, but even if your chamber is uninsulated, and serving as one electrode, you still won't get shocked. You've gotta have two points of contact to get a shot.

ah sorta like power lines right?

if this is the case i think the spark plug is the way to go

Posted: Sun Apr 17, 2011 1:20 am

by jackssmirkingrevenge

put simply:

Posted: Sun Apr 17, 2011 1:09 pm

by Major Collins

haha good one jack , made me laugh . Well that's good to see

Posted: Sun Apr 17, 2011 1:17 pm

by Fnord

Painfulbutdeliberatebackwardssmileyface