making inline vortex in 3/4"?

Hey all-

I want to make an inline vortex in 3/4" pipe, and I was looking for some tips.

I konw noname did it, and I believe he used 1/4" thick acrylic for the block?

So I was just wondering what any of you thought.

I was going to use .177 steel bb's.

I may up it to 1" as well we'll have to see

I want to make an inline vortex in 3/4" pipe, and I was looking for some tips.

I konw noname did it, and I believe he used 1/4" thick acrylic for the block?

So I was just wondering what any of you thought.

I was going to use .177 steel bb's.

I may up it to 1" as well we'll have to see

Tip: don't do it. Unless of course you've built at least 2 or 3 other vortex guns previously. Trying to make a block to fit 3/4" PVC will frustrate you like no other and probably put you off vortexes for a while.

Bump it up to 1" for sure, 1" SDR if you can find it. The reason that 3/4" PVC is so hard to use for a body is that BBs need to be able to flow in around the sides of the block. If the block is made of material of perfect thickness, 1/2", then BBs can't fit into the block smoothly simply because there isn't enough space.

1" SDR is my favorite size of pipe to use as the body because it's super easy to work with and allows lots of room for BBs.

Or you could probably make a 3/4" sidestrafer without too much extra effort.

Bump it up to 1" for sure, 1" SDR if you can find it. The reason that 3/4" PVC is so hard to use for a body is that BBs need to be able to flow in around the sides of the block. If the block is made of material of perfect thickness, 1/2", then BBs can't fit into the block smoothly simply because there isn't enough space.

1" SDR is my favorite size of pipe to use as the body because it's super easy to work with and allows lots of room for BBs.

Or you could probably make a 3/4" sidestrafer without too much extra effort.

Ok thanks-I just want a small vortex that is very portable almost pocket sizes. Would you do a 3/4 side strafed just in PVC like fnord did with his?

Also, I would like to be able to use this with high pressure possibly co2. Would you recommend stepping up to metal? Or would PVC still be ok- I would think go to Metal? But what do I know

Also, I would like to be able to use this with high pressure possibly co2. Would you recommend stepping up to metal? Or would PVC still be ok- I would think go to Metal? But what do I know

- inonickname

- First Sergeant 4

- Posts: 2606

- Joined: Sun Dec 07, 2008 3:27 am

How about a vortex cap?

Unless your regulating it down, you should know CO2 to be unsuitable.

Unless your regulating it down, you should know CO2 to be unsuitable.

PimpAssasinG wrote:no im strong but you are a fat gay mother sucker that gets raped by black man for fun

Inonickname, a vortex cap is a sidestrafer. Literally.

Ilovetoblowthingsup, regulated CO2 should be alright. However, this is only a should. BBMGs run less than 5 psi usually, under 10 always (unless you have a good detent). The gun will get really cold but I personally don't think it would crack. Going to metal is probably overkill, but you could use ABS if you can find sizes small enough. Then again, PVC may work just fine. You never know until you try.

Ilovetoblowthingsup, regulated CO2 should be alright. However, this is only a should. BBMGs run less than 5 psi usually, under 10 always (unless you have a good detent). The gun will get really cold but I personally don't think it would crack. Going to metal is probably overkill, but you could use ABS if you can find sizes small enough. Then again, PVC may work just fine. You never know until you try.

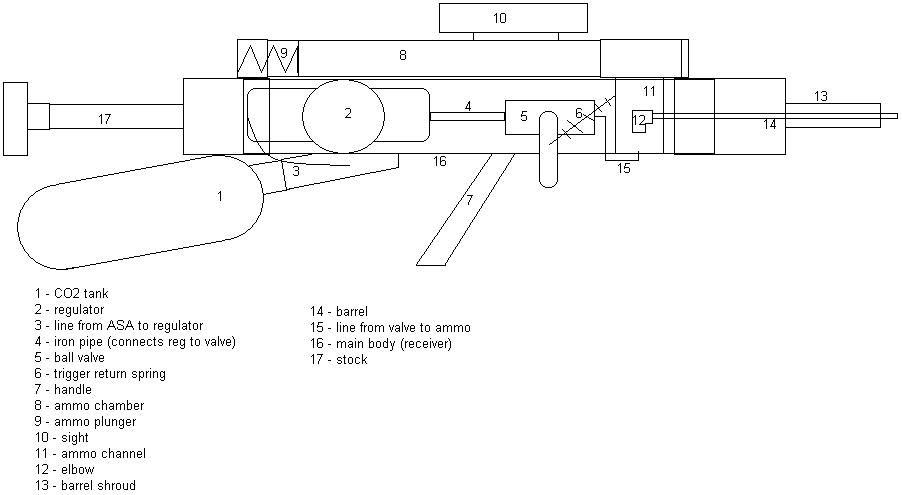

Here is a quick sketch of a BBMG I built a while back.

This one used a feeding system introduced by brianthebrain and worked wonderfully. I regulated the CO2 down to about 300psi and it would shred.

The ammo channel in the diagram was 3/4" pvc, but it had enough room underneath the elbow to allow proper circulation. Of course, it did take a little bit of adjustment to get right.

As far as the vortex cap goes, I just couldn't get it to work with this project. As noname said, it fed for a little bit then jammed up pretty nicely.

This one used a feeding system introduced by brianthebrain and worked wonderfully. I regulated the CO2 down to about 300psi and it would shred.

The ammo channel in the diagram was 3/4" pvc, but it had enough room underneath the elbow to allow proper circulation. Of course, it did take a little bit of adjustment to get right.

As far as the vortex cap goes, I just couldn't get it to work with this project. As noname said, it fed for a little bit then jammed up pretty nicely.

Ok-but you would definitely say unregged co2 is a no no? I'm thinkin I'm gonna do it in 1.25 and double sleeve it to be safe- perhaps I'll try unregged co2.... I dunno. I really wanna do co2 but like the flexibility of workin with PVC slot

Since the chamber is never actually sealed, it won't hold any pressure. But it's still over 800 psi. An unnecessary risk for me to take considering I wouldn't be gaining too much more power.

-

THUNDERLORD

- Sergeant 3

- Posts: 1264

- Joined: Fri Mar 28, 2008 1:42 pm

PVC bursts into perfectly sized shrapnel...

Although not too dangerous alone, when filled with BB's and held near one's body, it will be.

Besides PVC weakens with the cold CO2 will definately provide.

You mentioned "120 PSI"...My idea is to upturn a propane tank, held on a belt hook (similar to carrying a canteen),

Then add an insulated case for the tank and insert hand warmer packs inside that.

That should yield around 200psi consistently.

For a BBMG design, I've been dreaming up one with a "y" shape.

It will use a ball detent similar to JSR's innovation.

The mag will have a bulk gravity feed into a section inline with the muzzle,

The air/gas shoots in at around a 45 angle on the "y" and between the front BB and the one behind.

It should definately only fire one BB in the barrel at a time and very rapidly fire them too!!!

Maybe you could beat me to it??? 8)

EDIT: @HUBB: Got a linky for that awesomeness there?????????

Although not too dangerous alone, when filled with BB's and held near one's body, it will be.

Besides PVC weakens with the cold CO2 will definately provide.

You mentioned "120 PSI"...My idea is to upturn a propane tank, held on a belt hook (similar to carrying a canteen),

Then add an insulated case for the tank and insert hand warmer packs inside that.

That should yield around 200psi consistently.

For a BBMG design, I've been dreaming up one with a "y" shape.

It will use a ball detent similar to JSR's innovation.

The mag will have a bulk gravity feed into a section inline with the muzzle,

The air/gas shoots in at around a 45 angle on the "y" and between the front BB and the one behind.

It should definately only fire one BB in the barrel at a time and very rapidly fire them too!!!

Maybe you could beat me to it??? 8)

EDIT: @HUBB: Got a linky for that awesomeness there?????????

-----SPEED,STRENGTH, AND ACCURACY.-----

"Procrastination" is five syllables for "Sloth".

Theopia 8)

Born To Be Alive!

"Procrastination" is five syllables for "Sloth".

Theopia 8)

Born To Be Alive!

- Davidvaini

- Sergeant 4

- Posts: 1315

- Joined: Tue May 29, 2007 8:58 pm

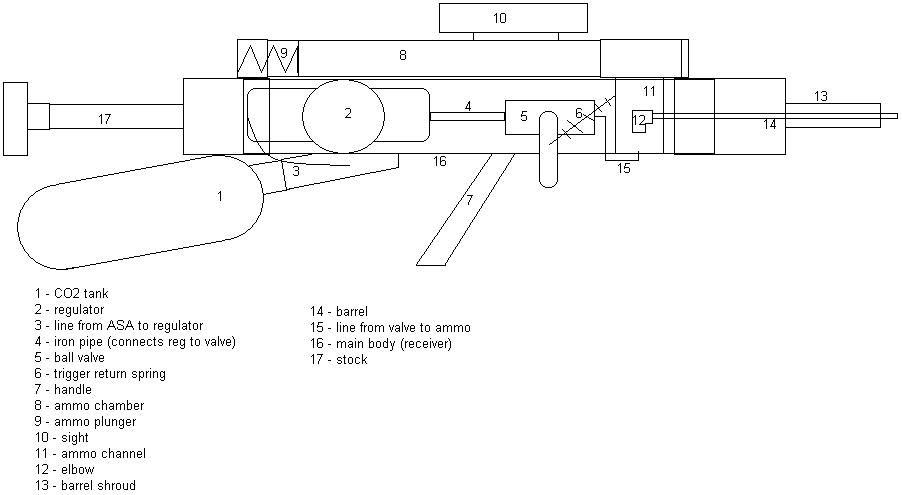

a vortex cap uses the same exact concept as a inline vortex.. but instead of making a block, you are using the circular shape of a pvc pipe/cap instead of the circular shaped carved out of a block.

The air inlet and the barrel are in the same position, the air spins the same way.. the only thing is.. since you are using the shape of the pvc pipe itself, you can incorporate it into smaller applications.

So you can build a 1 inch.. and it would fit in your pocket.

The air inlet and the barrel are in the same position, the air spins the same way.. the only thing is.. since you are using the shape of the pvc pipe itself, you can incorporate it into smaller applications.

So you can build a 1 inch.. and it would fit in your pocket.

-

THUNDERLORD

- Sergeant 3

- Posts: 1264

- Joined: Fri Mar 28, 2008 1:42 pm

It will fit in your pocket?...So you can build a 1 inch.. and it would fit in your pocket.

-----SPEED,STRENGTH, AND ACCURACY.-----

"Procrastination" is five syllables for "Sloth".

Theopia 8)

Born To Be Alive!

"Procrastination" is five syllables for "Sloth".

Theopia 8)

Born To Be Alive!

- Davidvaini

- Sergeant 4

- Posts: 1315

- Joined: Tue May 29, 2007 8:58 pm

yes you can do the same mag setup that the RC-P240 has.. and you could use a co2 inflator to really make it pocket size and portable.

Just use a D-Mag style setup.. and use a co2 inflator and it would fit in your pocket and you could even have multiple magazines in the other pocket if you wanted.

Just use a D-Mag style setup.. and use a co2 inflator and it would fit in your pocket and you could even have multiple magazines in the other pocket if you wanted.