Page 5 of 6

Posted: Sun Aug 21, 2011 5:45 am

by Labtecpower

You must be f***ing frustrated

Can you take a picture?

Posted: Sun Aug 21, 2011 5:53 am

by django

Labtecpower wrote:You must be f***ing frustrated

Can you take a picture?

I tried heating it with a lighter and removing with a Threader but it wont budge,I'll have to take it to work and see if they have anything small enough to remove it.... cant really take a pic at the moment mate,this gun has been my most frustrating yet ,LOL!

Posted: Sun Aug 21, 2011 10:57 am

by POLAND_SPUD

this gun has been my most frustrating yet

the underlying principle of operation is really as simple as it can get... JSR probably thinks that a valveless gun is simpler but it isn't as reliable

the broken threaded part is really small dia and no idea how im going to get it out

This has happened to me too. I was lucky that I didn't use loctite as the fitting had a small rubber washer that formed a seal when the fitting was threaded all the way in

Posted: Sun Aug 21, 2011 11:02 am

by Gun Freak

Posted: Sun Aug 21, 2011 5:00 pm

by django

Gun Freak wrote:

I did!,but on that fitting I used Loctite as the threaded part was tiny

Posted: Sun Aug 21, 2011 5:17 pm

by Gun Freak

Could have used a tiny piece of Teflon tape

Posted: Sun Aug 21, 2011 8:00 pm

by saefroch

Instead of laying it flat like tape, let it roll up so it becomes ropelike, if the threads you're putting it on are really short.

Posted: Mon Aug 22, 2011 3:50 am

by django

Look it doesnt matter whats done is done= we got it out at work very easily by grinding 4 flat sides onto a needle prong from a pnuematic needle gun and and lightly tapped it into the hole,heated up the area very slightly with a lighter and it twisted out 8) .

I now have to get hold of another brass adaptor,maybe I should try find a stronger fitting that will screw into the back of that cylinder but be able to attatch to that 1/4" nipple?.....

Posted: Mon Aug 22, 2011 4:05 am

by POLAND_SPUD

yeah you can... but you might as well use two push to connect fittings plus a short lenght of tubing

Posted: Sat Aug 27, 2011 3:04 am

by django

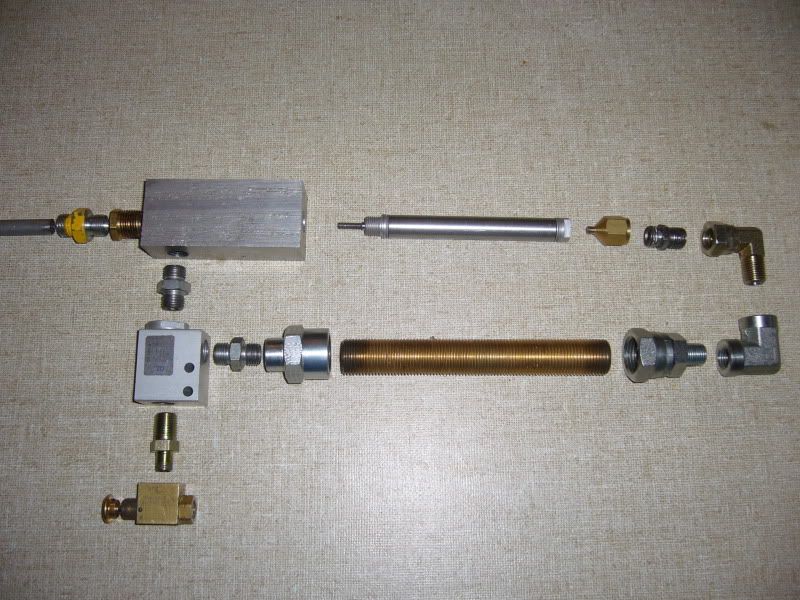

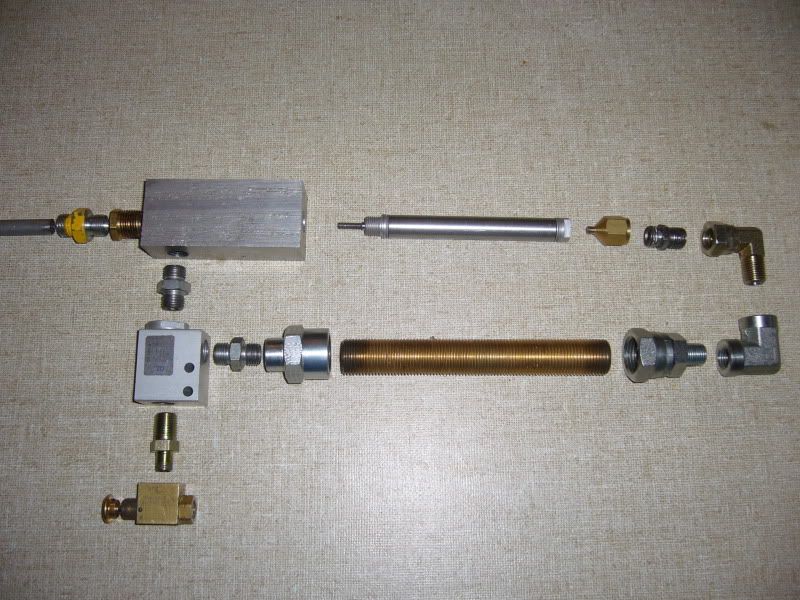

I went and got another Brass Airbrush Fitting again today and put the gun back together= its still not working right?.

Very often a BB will roll out the barrel even though I have x 2 rare earth magnets at the front of the block( breech area) and also quite often will not feed a bb in from the bb inlet, sometimes it will double feed too,WTF?.

I dont think the Piston I made on the Cylinder Rod is jamming as it still loses a reasonable amount of air through the BB inlet at the back of the block.....

EDIT:

I screwed the barrel off to see whats going on =If I pressurise the gun and cylinder rod is out then drop a bb in the bb inlet on the block,then push the trigger,qev fires ,the rod retracts and the bb drops down into the block but now when I let go of the trigger the rod flies forwards as it should but it does so with so much force that the bb pops right out of the block.

The Cylinder seems to have too much force so the bb gets pushed out hard and rolls out the barrel before you can take the shot.I doubled up the magnets and it still plays up and they are REALLY STRONG magnets.

I dont even think a detent will hold the bb inplace?,what do you guys use to make sure the bb doesnt roll away like mine is??!. the whole thing just doesnt feed correctly with double feeds or no feeds constantly

Posted: Sat Aug 27, 2011 6:59 am

by POLAND_SPUD

I rolled a lenght of teflon tape into a string and that was enough to stop them

a rubber washer/ o-ring detent should do the trick as well

Posted: Sat Aug 27, 2011 7:24 am

by Crna Legija

I had the same problem, i just put a dent in the side of the barrel and it solved it.

It takes a bit of fine tuning to get it all working good, i had double feeds too. to solve it i put a dent right in font of the BB input so one BB gets stuck in there until the rod pushes it out

Posted: Sat Aug 27, 2011 8:26 am

by django

Thanks guys, I thought it was just me being useless? I'll try put an O-ring in there or dent the barrel plus the dent near the BB feed.

Still cant figure out why sometimes it doesnt feed at all though??,I took the barrel off and cycled the rod/piston over and over for ages and it functioned 100% with no rod jams. Yet theres times I can push the button 2-3 times before the next round drops down!? I cant see why

Posted: Sat Aug 27, 2011 9:29 am

by Brian the brain

Experienced licenced gunsmiths sometimes have trouble making a gun work first time. ( as can be seen on Discovery Channel's "sons of guns")

Every once in a while they have to tinker too to get them to cycle...so don't beat yourself up if at first you don't succeed...

You know what they say..

Posted: Sun Aug 28, 2011 7:01 am

by django

Today I tried with a Nick in the barrel, no good then tried an o- ring itt blew out the barrel after a few shots.

I then drilled a hole in the barrel and made a spring/ball detent, it was made like my last gun( held together with Steel Putty) the gun seemed to function much better and nothing rolling out the barrel.

After about 20 shots the detent blew apart! and scared the hell out of me

, the tube stayed on the barrel but the nut on the end and the bb/spring went flying. luckily it was made with detent facing the ground.

I never had this problem with my other gun and the detent is made the same but I only allowed 1 hour for the Steel Putty to harden which is the time stated on the tube.I'll have to try get it silver soldered on instead