Page 2 of 3

Posted: Sat May 03, 2008 2:14 pm

by Flash

SPG wrote:A speed control would provide variable rate of fire, and a simple bit of circuitry on the back of the motot could make sure that the barrel always stopped in the AIR CLOSED position.

What kind of circuitry are you talking about exactly? And would I be able to buy a speed control and an electric motor at, say, Radio Shack?

EDIT: I just found

this one, and I was wondering if it would provide enough torque.

Posted: Mon May 05, 2008 5:51 am

by SPG

Err, no I doubt it'll work and also it's got an insanely high rpm, which would give you an insanely high rate of fire. It's listed as having a no load speed of 24,000 rpm, even if we divided that by four for the load, does anyone have 6000 BBs they can fire per minute?

If you can I'd go for an RC car motor, in fact if you can find an old RC car in a dumpster or somewhere get the whole thing, as you'll get a decent hi-torque motor, a speed controller and some gears to play with. Just think you could make an RC-BB-MG.

As for the electro-mechanical circuitry, here's a rough diagram, which should work, it's based on how wiper motors work in cars. You can see the two micro-switches are wired in parallel to the motor and battery, the rotating disc is attached to your motor.

CLICK IMAGE FOR ANIMATION:

Squeeze and hold the trigger and the circuit is made and the motor rotates continuously; release the trigger and the motor continues to rotate (because the second microswitch is now also making a circuit) until the notch allows the microswitch to open, and the circuit is now broken.

Posted: Wed May 07, 2008 8:34 pm

by Flash

Wow, that looks really great. But do you know of a way to make the bolt stop at the closed position for a certain amount of time? Ideally, I would want the bolt to spin as fast as it can until it seals. Then it would stop for a specified duration, which can somehow be controlled. Finally, it would spin as fast as it can to the open position. It would be fine if it was only semi-auto.

I also plan on using paintballs or something with a similar mass.

Posted: Sun May 11, 2008 7:44 pm

by iknowmy3tables

you know a rotating seal like that wont seal with orings, you'll need a vinyl tube seal

Posted: Mon May 12, 2008 2:20 am

by SPG

I don't think it needs a seal at all. What's I'd suggest is that any "trigger" not only works to control the electric motor but also acts to open the gas valve.

Sure a little bit of gas is going to leak and be wasted WHILE you're in the firing cycle but the main time you want a tight seal is when you're not firing.

As for making the motor stop at a specific position with each cycle I'm sure it can be done, but I can't personally work out how to do it, I thinkit'd need some form or micro-processor control and that's well beyond me, I'm more an electro-mechanical kind of guy.

BUT is it needed? A couple of questions for you.

1) What rate of fire are you aiming for?

2) What gas pressure are you using?

If we know the answers to these two we can work out the optimum "valve" opening time using GGDT. For the BBMG I tried GGDT suggested a valve opening time in milliseconds using unregulated CO2. So I'd suggest attempting a rough GGDT model with your figures to work out if having the valve hold open is really necessary.

Posted: Mon May 12, 2008 5:50 pm

by Flash

[quote='iknowmy3tables']you know a rotating seal like that wont seal with orings, you'll need a vinyl tube seal[/quote]

Oh yeah I realized that the o-rings won't seal. Do you think strips of rubber around the breach will seal it? And what are vinyl tube seals, just using vinyl tubing as the sealing face?

SPG- I plan on using a low pressure of about 50 psi, 100 at max. I can't use anything more than that because the materials I'm using aren't rated for anything more. Since I'm using a low pressure, I think I need something with higher flow than a shrader valve.

For the ROF, I'm thinking I'll at least get 3 bps at 50 psi with 10 bps being great and 30+ being amazing. Although I doubt that 30 bps is possible with even 100 psi.

Thanks

Posted: Fri May 23, 2008 11:25 am

by Flash

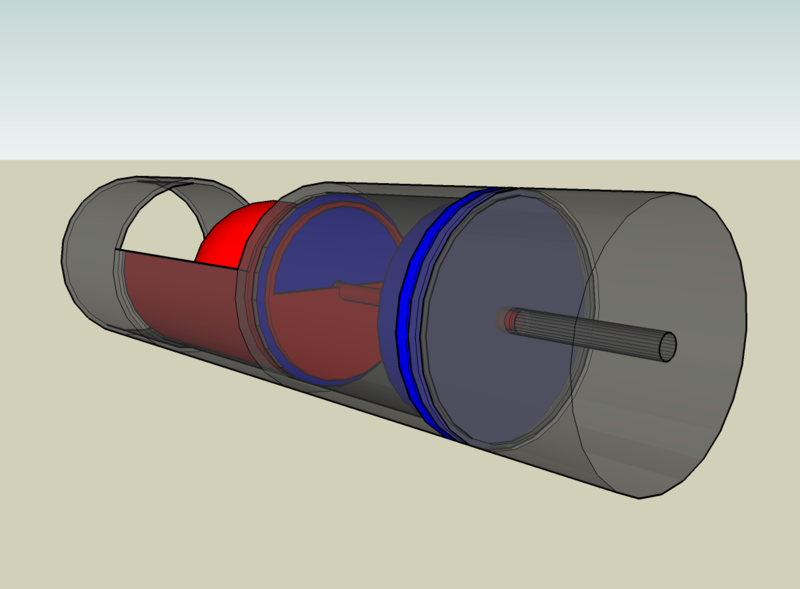

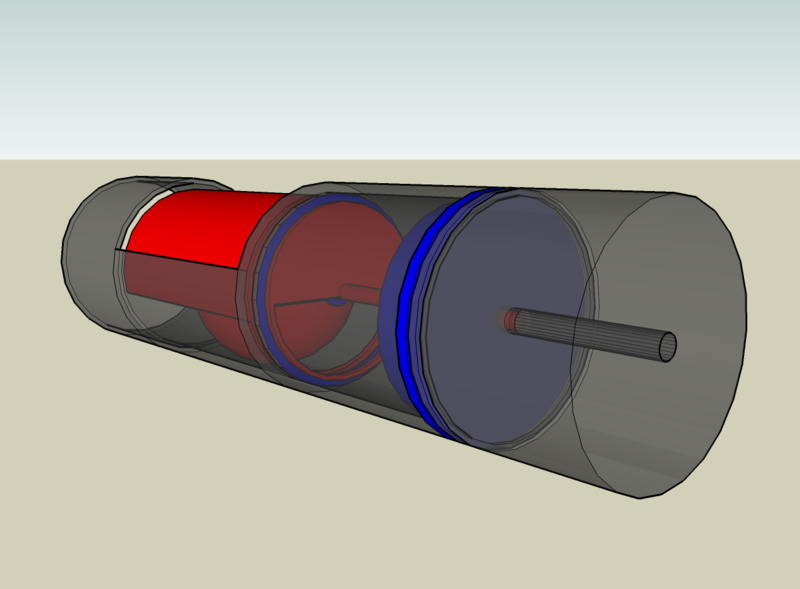

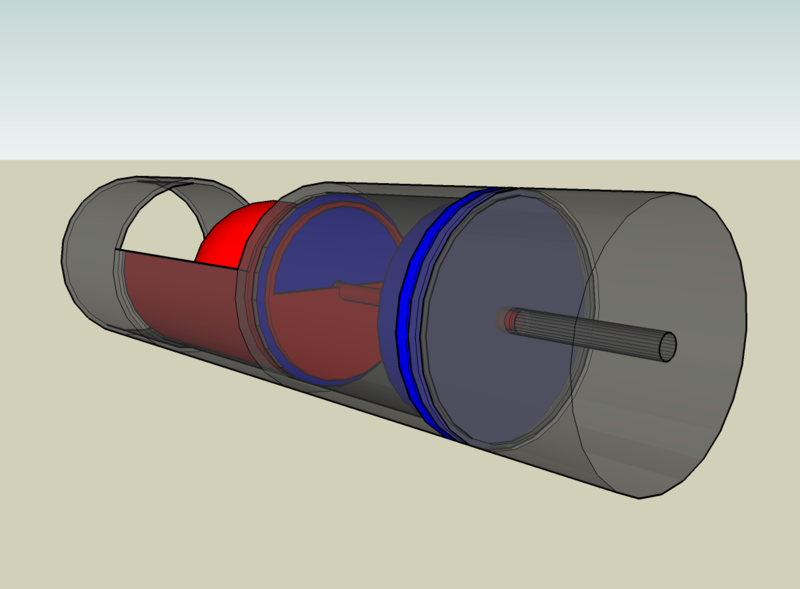

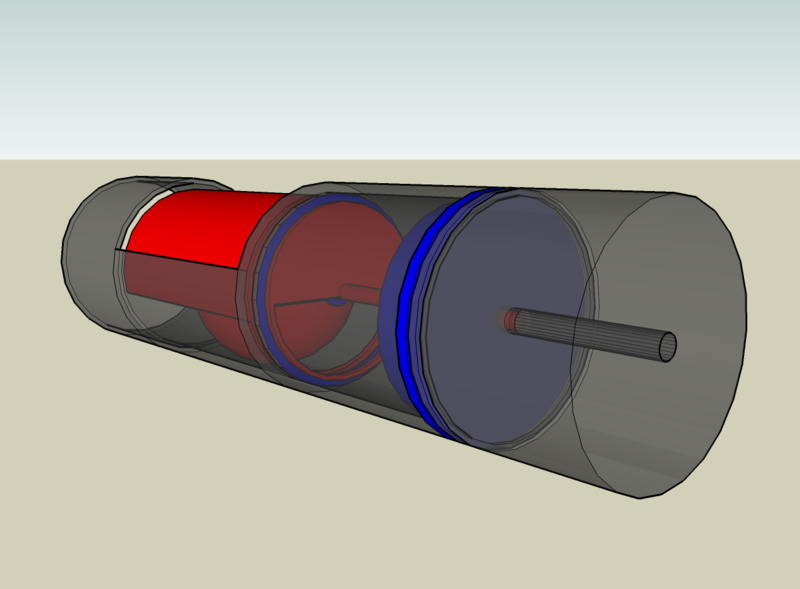

I redesigned the valve so its flow is slightly better.

Valve closed/ breech open

Valve open/ breech closed

On a side note, does anyone know much about circuit boards? I was researching paintball guns, and noticed that most electro-pneumatic guns used a circuit board to control how long a solenoid stays open.

Posted: Fri May 23, 2008 12:19 pm

by THUNDERLORD

@Flash, if a bolt/valve like the one in your pic shows works, you wouldn't need a solenoid because it could have constant airflow.

But anyway a solenoid is just a ferrous rod in a electro-magnetic coil. So a solenoid will stay open as long as current is run.(or reverse depending on the spring).

A capacitor can be used for timing the length it's on or a momentary switch, which wouldn't need a circuit board. jimmy 101 drew a capacitor schematic one time but I can't find the post now.

Posted: Fri May 23, 2008 2:23 pm

by Flash

Thanks. But I don't need a circuit board to control a solenoid valve. I was using it as an example. So, do you think a capacitor can:

...make the bolt stop at the closed position for a certain amount of time? Ideally, I would want the bolt to spin as fast as it can until it seals. Then it would stop for a specified duration, which can somehow be controlled. Finally, it would spin as fast as it can to the open position. It would be fine if it was only semi-auto.

Thanks again for all the help.

EDIT: I read about capacitors on How Stuff Works and Wikipedia and I don't see how it would be able to control when the bolt spins.

Posted: Sat May 24, 2008 8:03 am

by psycix

Flash wrote:I redesigned the valve so its flow is slightly better.

<images>

I dont think thats very good.

Why?

Look at it carefully. Say the closed state is called 0 degree and the open state 180, and 360 being closed again.

If its on 1 or maybe 5 degree, its already openening, and up to 355 or 359, it is open somewhat..

Its only completely closed a very short amount of time.

Posted: Sun Jun 08, 2008 10:00 pm

by Flash

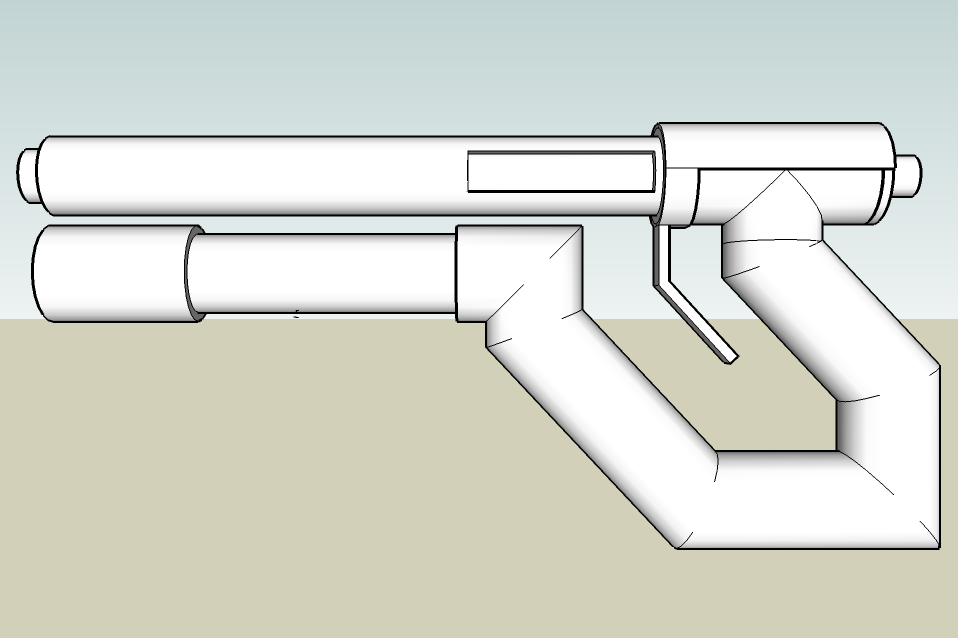

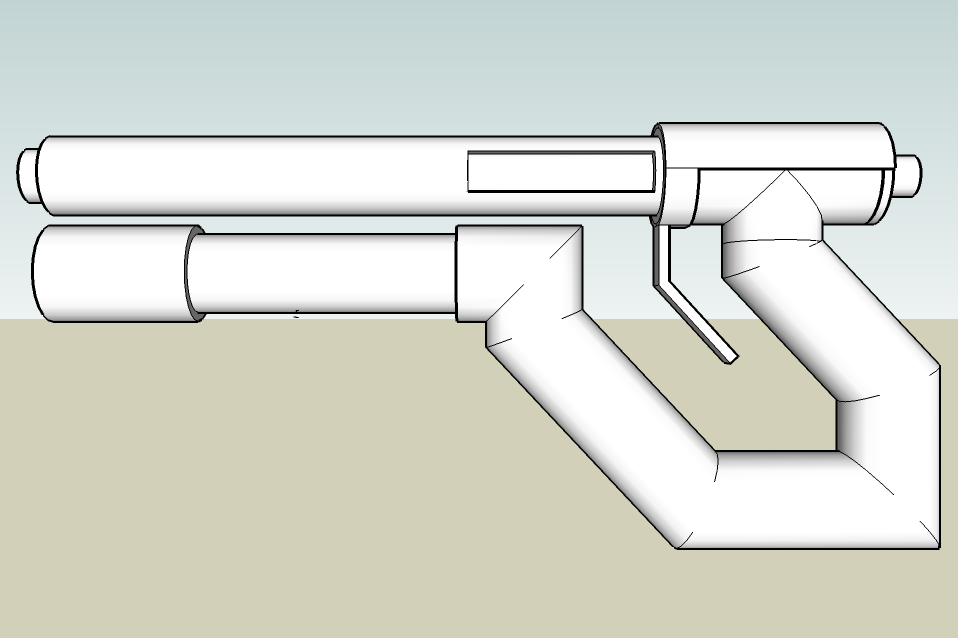

I simplified the gun enough so it could be made mostly out of PVC parts.

I'll explain more later, I have finals tomorrow.

Posted: Mon Jun 09, 2008 6:05 am

by jackssmirkingrevenge

Flash wrote:For the ROF, I'm thinking I'll at least get 3 bps at 50 psi with 10 bps being great and 30+ being amazing. Although I doubt that 30 bps is possible with even 100 psi.

Rate of fire depends entirely on how fast the breech is spinning, it has nothing to do with pressure.

In order to avoid complex controls, just have the motor wired directly to a switch, which you then combline with a blowgun trigger - this means that letting go of the trigger not only stops the motor but also cuts off the airflow, so you don't have to worry about 100% sealing of the breech or where the breech stops when you let go of the trigger.

Posted: Mon Jun 09, 2008 11:32 am

by SPG

Although of course you'd like it to stop with the port not completely open to the magazine, or all your projectiles will roll out the barrel.

And RoF surely would also depend on pressure too, and on "port" size, and opening time. The point would surely be that the higher the pressure you've got the shorter the port/valve needs to be open to achieve the same power. See what I mean?

Posted: Mon Jun 09, 2008 2:42 pm

by jackssmirkingrevenge

SPG wrote:Although of course you'd like it to stop with the port not completely open to the magazine, or all your projectiles will roll out the barrel.

An o-ring would not only prevent this but also allow pressure buildup before the projectile fires, increasing power

And RoF surely would also depend on pressure too, and on "port" size, and opening time. The point would surely be that the higher the pressure you've got the shorter the port/valve needs to be open to achieve the same power. See what I mean?

Fair comment, but we're talking round per minute, not ft/lbs per minute,

n'est pas?

Posted: Mon Jun 09, 2008 3:34 pm

by Flash

Okay, so the piece behind the tee is a gear similar to the one that allows nerf gun barrels to rotate. When the trigger is pulled back, the bolt spins 180 degrees and when it is released, it spins another 180 degrees. Although the valve is open only as long as the trigger is held back, I can control how much air is in the chamber by pumping only as many times as I want. The gun is no longer semi-auto, but it is now portable and will let me know how well a spinning bolt seals.

jackssmirkingrevenge wrote:An o-ring would not only prevent this but also allow pressure buildup before the projectile fires, increasing power Wink

Thanks. I completely forgot about having a ball stopper. But I don't think the prototype needs anytime for the pressure to build up.