AWW! It seems like every time I think I come up with some great idea, someone else beat me to it.

SPG wrote:

Cons

[1]Fine tolerances

[2]Needs batteries

[3]At very high ROF the power will drop due to insufficient gas entering the barrel

And I even built one - and it leaked like a seive (but then I didn't know what I know now) and GGDT lied.

Go for it I say, like I said we've moved on a lot since that post, and I reckon it's very do-able.

1. I think I can fix that with some parts from Mcmaster, they have polyester tubing in various diamters. I can also throw in a couple o-rings to fix any seals

2. I don't know much about motors (its on my list to wikipedia), but I hoping that a simple 9 volt will give it enough juice.

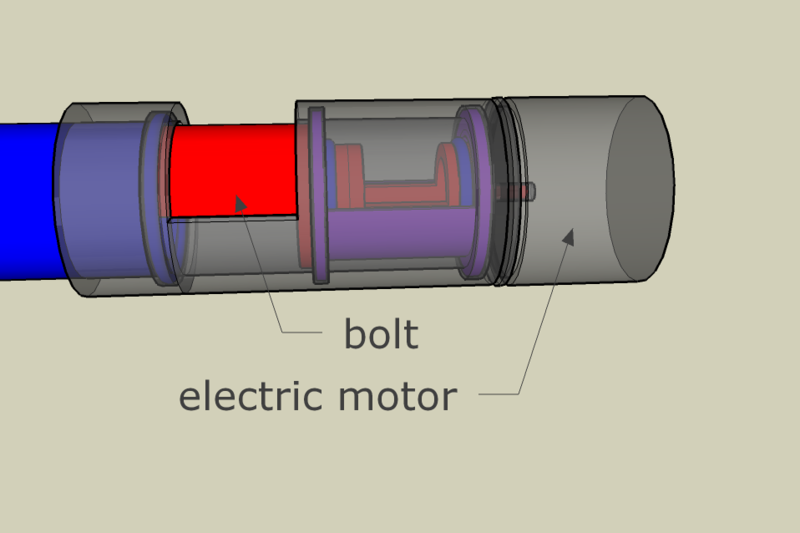

3. I was thinking about using that space that controls when the gas is allowed to flow through the bolt as a firing chamber. This should increase the flow.

I'm also planning on designing a valve that cuts off air the chamber when the trigger is pulled

You said you built one? Did you have any problems with it jamming? The more I think about it, the bigger the problem becomes, especially with paintball size rounds.

jackssmirkingrevenge wrote:In terms of geometry, it's a much better idea to have the bolt spinning on an axis perpendicular to the barrel, as opposed to coaxially as in my prototype.

Why is it better to have it spin perpendicular to the barrel?

After reading yours and SPG's topics, it seems like the biggest problem with these things is just the seal. I'm definately using real o-rings for the rotating valve, but what do you guys think about making the actual bolt out of a slightly stiff foam or a semi-hard rubber? I would have to sacrifice some of the ROF, but thats the only way I can think of to seal the entire breach.