Page 6 of 6

Posted: Fri Jun 04, 2010 9:12 pm

by ramses

axi0m wrote:Also, with a cylindrical charge in a cartridge, one could have an igniter that was placed along the length-wise axis of the cartridge

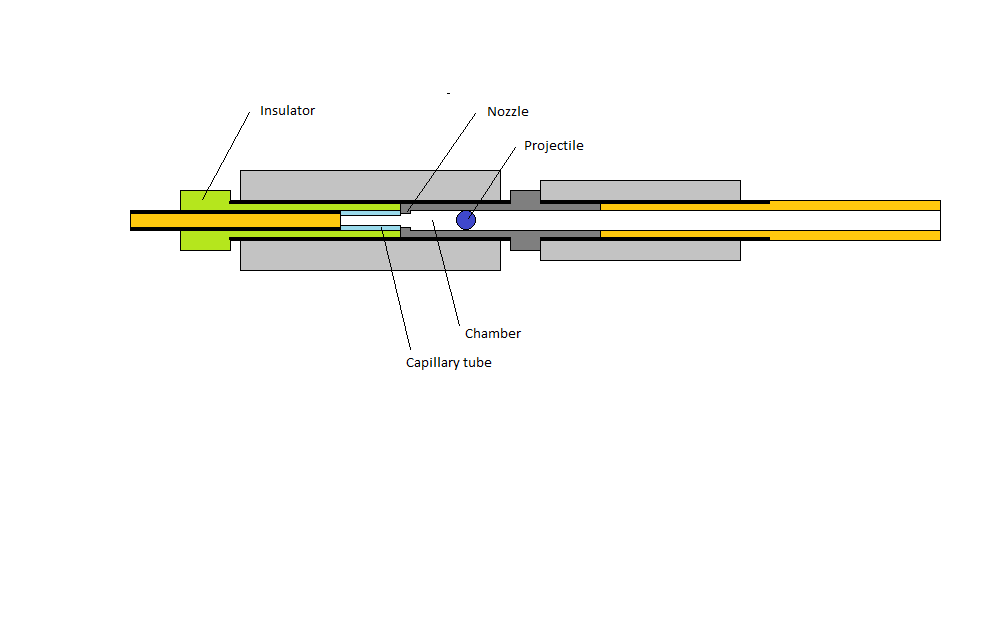

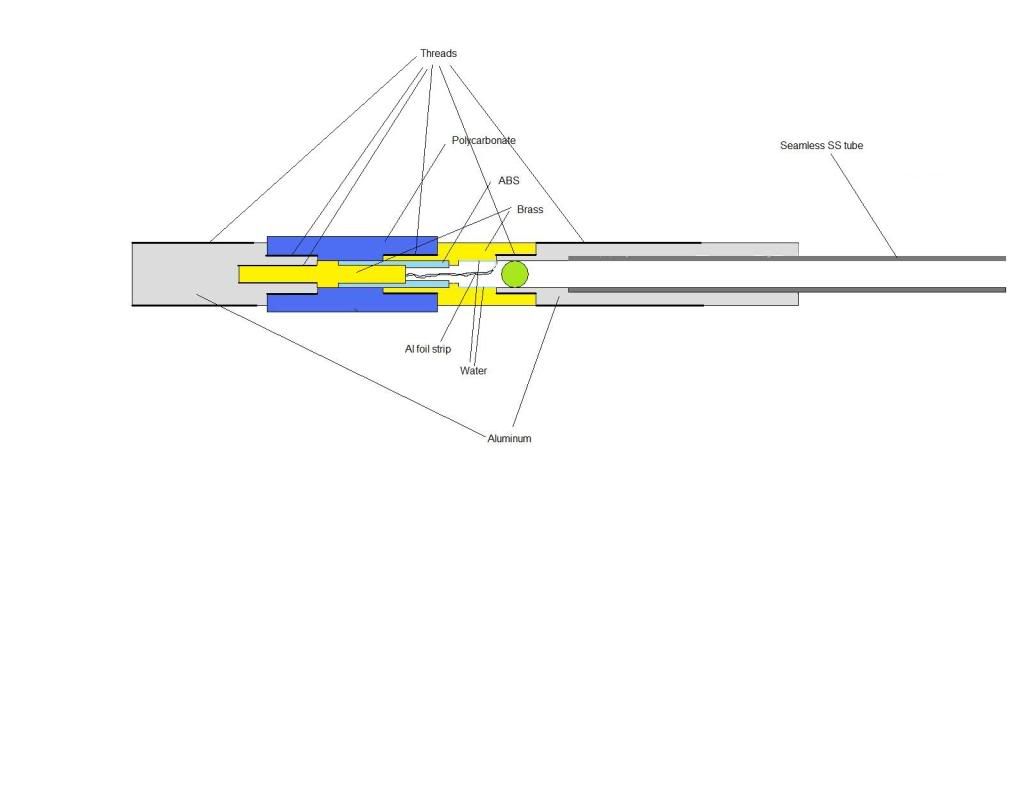

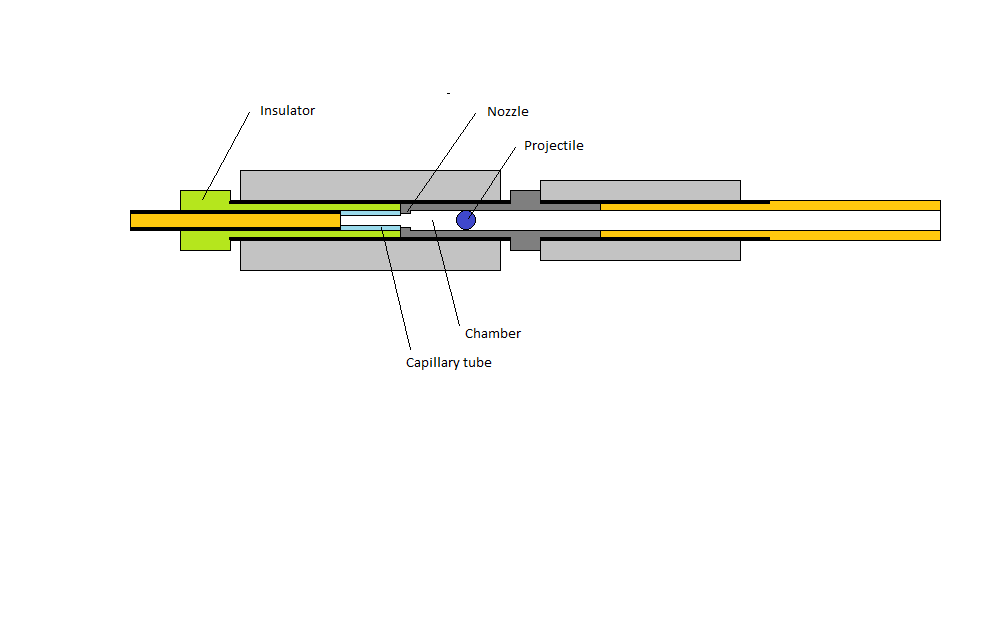

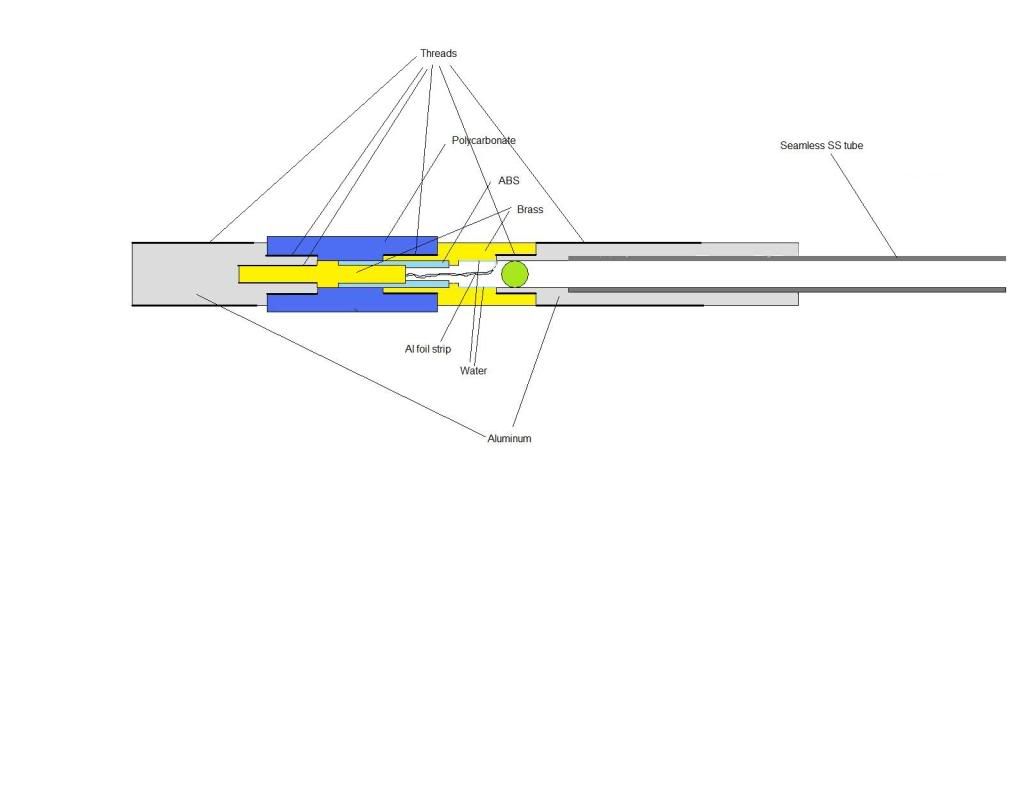

It has been done. I think that is pretty much the best possible geometry for this type of ablation.

Here is the link to the book entitled "Theory of High Speed guns." It was linked to previously, but I thought some may not have seen that thread.

Posted: Fri Jun 04, 2010 9:28 pm

by axi0m

ramses,

I see that you posted a picture of an ETG. I was referring to chemical propellants.

A problem, however, with that design is that the rate of the release of gas increases linearly, while the volume behind the projectile increases exponentially.

My quest was to find a method of using conventional or ETG propelling systems to maintain the full maximum allowable pressure for the entire barrel length such that the projectile maintains the highest acceleration possible for the entire length of the barrel, as is possible with a railgun.

Posted: Sun Jun 06, 2010 11:47 am

by ramses

Do you mean that the volume increases quadratically with time (y=x^2)

Strictly speaking, exponentially means that it increases as y=k^x

Gas release of a monopropellant would increase linearly, but what matters is the total gas, or integral. Integral is also what matters for the total volume behind the projectile.

I really need to take physics and calculus.

Posted: Sun Jun 06, 2010 6:05 pm

by axi0m

The point, ramses, is that they do not change at the same rate, which they should to maintain the maximum pressure.

Posted: Sun Jun 06, 2010 8:28 pm

by ramses

yes, but they might be close. One of those papers did mention a cone shaped cartridge. I think that would tend to erode the neck a lot, but it should be better than perhaps double the pressure spike.

Posted: Thu Jun 10, 2010 6:17 pm

by Zeus

Such a cartridge will provide constant pressure, at the breech,

not the muzzle.

For sub mach 2 projectiles, a "shaped charge" would help, but past that,

it's hard to keep the gases at the base of the projectile for the whole

length of the barrel.

I thought that if the projectile was injected into a tube of

propellent, and the back of said tube was ignited as the projectile

passed through. It would be hard to do, but most of this thread

containing solid propellents is theory, so difficulty isn't a factor.

In regards to light gas guns, I've found that 50mm threaded

SCH80 steel tube is quite hard to get. So I've decided on

25mm tube. If that works I'll go for 50mm steel.

I've also found an ideal HDPE piston. I'll post a picture soon.

(Sorry, this may double post. 20Kb average internet speed)

Posted: Fri Jun 11, 2010 12:55 am

by axi0m

Zeus wrote:Such a cartridge will provide constant pressure, at the breech,

not the muzzle.

For sub mach 2 projectiles, a "shaped charge" would help, but past that,

it's hard to keep the gases at the base of the projectile for the whole

length of the barrel.

I understand what you are saying about the pressure disparity between the breech and the muzzle. Obviously one common way to counter this is to use pellets of propellant that are accelerated along the barrel with the projectile. I do not, however, know of a single pellet geometry that increases its surface area once burning initiates. I'm not sure if that is mathematically possible.

Posted: Fri Jun 11, 2010 10:21 am

by ramses

The BATES grain keeps a fairly constant surface area... If you kept the ends from burning, the SA would increase. Another plausible solution would be the truncated cone-shaped grain, burning from the small end. The issue with that is that the grain is smaller, even though it takes up the same cross sectional area in the barrel.

One could experiment with changing the composition of the grain such that fuel that would be burned later would burn faster. Something like a catalyst gradient. I have no idea how to manufacture that, except perhaps in a finite number of steps, each cast on top of the last...

Most propellants burn rates increase with pressure, so that could be exploited (carefully!)

Posted: Fri Jun 11, 2010 9:58 pm

by DYI

Keep us updated on your attempt, Zeus. Also, what you were describing halfway through your post is known as a "ram cannon". There's a paper floating around here on designing one for satellite launch, but I'm not sure where at the moment.

With current propellants and assuming (relatively) high launch speeds, the multi-chambered approach is the closest you'll get to constant projectile base pressure, and previous attempts seem to indicate that it's difficult to implement. Pushing some propellant along with the projectile to have it burn on the way may help somewhat, but I suspect there would be much efficiency lost to pushing all that extra mass. A ram cannon is a similar, and probably more efficient concept.

I think that many of the arguments for burn rate and charge geometry here have been based on an assumption of constant pressure through the system. It should go without saying that in the conditions involved, such an assumption is outlandish. As axi0m stated earlier, not in so many words, flow effects are the key limitation in all of these solid-propellant proposals.

As always, I'm intrigued by the various liquid propellant possibilities, and quite unable (due to my current situation) to test any of them. In the case of H<sub>2</sub>O<sub>2</sub> and H<sub>2</sub>O, addition of aluminum to produce hydrogen may increase the sound speed at the expense of efficiency, through the production of solid aluminum oxide. This is desirable in some cases, but I don't know exactly how the system would behave. All of these propellants would, of course, do better in conjunction with a properly designed ET system.

@axi0m: railguns are not my topic, but you can get all the information you want (except on how to use one

) from rp181. What little I've read on them has led me to believe that building a hypervelocity railgun would be even more devilishly tricky than achieving the same thing through other means, and probably just as expensive.

Posted: Mon Jun 14, 2010 9:28 pm

by axi0m

DYI, ramses wasn't talking about a ram cannon. He was talking about a pellet configuration for a chemical gun that was made of two different types of propellant, one slow-burning and one fast-burning, such that the slow-burning section was ignited first and, as it burned, the concentration of the fast-burning propellant was increased.

ramses, I like your idea of a cone-shaped pellet, but I think I have one that is simpler. All you need is a tube whose outer surface is retarded from igniting with a preventive coating. Thusly, only the ID and possibly the ends would burn, increasing surface area significantly with time.

Also, if we implemented your catalyst gradient idea, the innermost section of the pellet would be made of a slow-burning propellant with the outermost section being made of a very fast-burning propellant.

edit:

Sorry, ramses, I didn't realize the bates grain shape was indeed tube-like, or hollow-cylindrical. I think my point still stands, if you prevent the OD from burning the ID will increase as is shown in the figure below:

Posted: Tue Jun 15, 2010 3:49 pm

by ramses

I believe you were the one describing a ram cannon.

I thought that if the projectile was injected into a tube of

propellant, and the back of said tube was ignited as the projectile

passed through. It would be hard to do, but most of this thread

containing solid propellants is theory, so difficulty isn't a factor.

A ram accelerator does basically the same thing, except the projectile pulls the flame front along with it, so all the combustion occurs at the base of the projectile. In a SCRAM cannon, the projectile is traveling faster than the local SOS, but still carries the flame front behind it.

I recommended something along the line of the BATES grain. Any time I have ever seen a a BATES grain, the ends are also allowed to burn, and that evens out the thrust somewhat, which is exactly the opposite of what you are trying to do.

With my catalyst idea, it might be MUCH easier to run the gradient in the axial direction, allowing however many "steps" of propellant to be poured in a straightforward manner (in a plain cylinder grain, burning from one end only)

The other possibility would be to pour a homogeneous propellant into the form with a catalyst content equal to the mean of what you want in the final grain, and then spin it in a centrifuge. I am not certain the centrifuge would actually produce a gradient, but if it did, I would think it would be an exponential (quadratic, since I made a fuss when you said it) gradient (as opposed to a linear one). Combined with the effect of burning outward, you might end up with a cubic gas volume curve, which may be what you want. If not, you could make the axial grain, possibly using the centrifuge technique.

Thank god I get to take physics next year.

Posted: Tue Jun 15, 2010 4:06 pm

by axi0m

Oops, DYI, I missed the fact that you were talking to Zeus -- and ramses I'm not sure who you are talking about in the beginning of your last post. Anyway...

The centrifuge would work if there is a significant difference in the density of the two propellent types. You could customize the gradient using different levels of Gs and by adjusting the duration.

Posted: Sat May 21, 2011 9:43 am

by DYI

I recently found a paper of high relevance to this thread's subject matter, dedicated to exploring the theoretical high velocity performance limits of gas dynamic guns. They present a means of launching macroscopic projectiles to speeds in excess of 20km/s without breaking apart during the acceleration.

I've uploaded the paper

here for your viewing pleasure.

The limiting factors which they identify, and which should be obvious to any experienced member here, are fracture of the projectile caused by excessive base pressures (in one case they discuss

velocity differences in the projectile in the range of thousands of metres per second) and radiative heat loss from high temperature gases (they measure their propellant gas temperatures in eV

).

The designs discussed in this paper are single shot (in the sense of the phrase where reloading is time consuming because the entire gun is destroyed during firing), but the strategies discussed for achieving high speeds are applicable to the kind of launchers we're more likely to be interested in. Using purely gas dynamic means and chemical reactions for propulsion limits them somewhat to using HE driven plates or LGGs to heat the gases to the required temperatures, but by "cheating" with electric heating of the gases...

I don't think my ETG project is going to run into significant barriers to higher velocities for quite a while yet.