spudgun range, are we falling short?

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

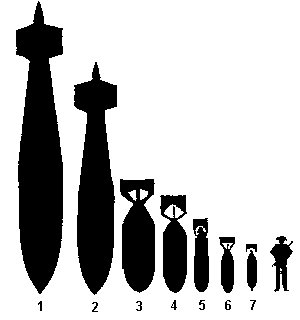

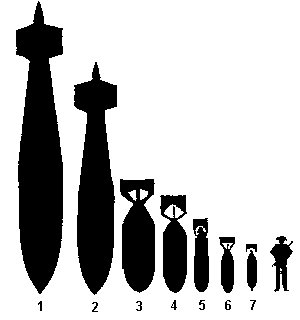

For range, I'm thinking of turning some shapes like this on a lathe..

Using a sabot in a larger bore to get the velocity up to something reasonable and I'm ready for a contest distance shot.

Using a sabot in a larger bore to get the velocity up to something reasonable and I'm ready for a contest distance shot.

- jackssmirkingrevenge

- Five Star General

- Posts: 26179

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 543 times

- Been thanked: 321 times

The Grand Slam (1) would approach the speed of sound by gravity alone, so it's a good design to emulateTechnician1002 wrote:For range, I'm thinking of turning some shapes like this on a lathe..

Given your fast valves and large bores I dare say you should get some pretty impressive numbers for a small saboted streamlined round.Using a sabot in a larger bore to get the velocity up to something reasonable and I'm ready for a contest distance shot.

hectmarr wrote:You have to make many weapons, because this field is long and short life

I think that for something close to 50 cal, using a conical or ball lead bullet, and casting hard resin as a tail and fins using a RTV rubber mold would be not difficult. A screw could be a nice and sturdy support.

I believe (by experience ) it would take about 5 to 7 minutes per cast to make such a missile/bullet in quantity.

) it would take about 5 to 7 minutes per cast to make such a missile/bullet in quantity.

Do you think it would work as more precise bullet, and would flight more strait?

I believe (by experience

Do you think it would work as more precise bullet, and would flight more strait?

- Attachments

-

- missiles.jpg (16.96 KiB) Viewed 2770 times

- jackssmirkingrevenge

- Five Star General

- Posts: 26179

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 543 times

- Been thanked: 321 times

It will certainly be more aerodynamic than a hollow tailed projectile. Brenneke type slugs use lightweight fibre or synthetic tails for this reason:LeMaudit wrote:Do you think it would work as more precise bullet, and would flight more strait?

You could always add dimples for MOAR POWAH!

Here's another way of doing it, with a lead nose and light balsa/foam tail section, and a central part of constant diameter to provide stability in the barrel.

- Attachments

-

- projectile.GIF (2.92 KiB) Viewed 2737 times

hectmarr wrote:You have to make many weapons, because this field is long and short life

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

It don't think it will work well (i.e. it probably won't be stable enough)Here's another way of doing it, with a lead nose and light balsa/foam tail section, and a central part of constant diameter to provide stability in the barrel.

Base drag might be a good thing as it shifts CP to the back of the projectile

Children are the future

unless we stop them now

unless we stop them now

- jackssmirkingrevenge

- Five Star General

- Posts: 26179

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 543 times

- Been thanked: 321 times

Fins would probably need to be added, but I'm wondering if having a dramatically forward CG would make them unnecessary.POLAND_SPUD wrote:I don't think it will work well (i.e. it probably won't be stable enough)

hectmarr wrote:You have to make many weapons, because this field is long and short life

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

Well there is just one way to check that... I modelled similar projectiles in rocksim (there is a thread or a post on it somewhere.

IIRC D_hall replied that the programme isn't good enough to model cd values and other things accurately... not to mention that it's optimised to work with rockets

Anyway whenever I tried to model a truly streamlined projectiles or just used a boat tail design the base drag dropped dramatically and that shifted the CP closer to the nose

IIRC D_hall replied that the programme isn't good enough to model cd values and other things accurately... not to mention that it's optimised to work with rockets

Anyway whenever I tried to model a truly streamlined projectiles or just used a boat tail design the base drag dropped dramatically and that shifted the CP closer to the nose

Children are the future

unless we stop them now

unless we stop them now

I think I will try to cast a tail in resin like a little bomb. I've done several hundreds of similar casts like that in the past. Like this picture (it is painted resin, about 1 inch long).

The only think I don't know is if the resin will not be crushed while in the barrel... but I guess all the pressure will be on the lead nose so it should be okay.

Now I'm thinking I need to resupply resin and rubber. My stock is too old... and I also badly need a gun now

The only think I don't know is if the resin will not be crushed while in the barrel... but I guess all the pressure will be on the lead nose so it should be okay.

Now I'm thinking I need to resupply resin and rubber. My stock is too old... and I also badly need a gun now

- Attachments

-

- K5_shell.jpg (7.74 KiB) Viewed 2678 times

- Mr.michael.2468

- Private 3

- Posts: 48

- Joined: Sat Jan 08, 2011 11:33 am

First the tech stuff, skip to bottom for how to and materials:

not to but in here guys, but again im going to make an advertisement for the design of bullets i've dreamt up in the image of shotgun slugs like you suggested, and also with the budget of a jobless 16 year old in mind, a sabot works because of the high center of gravity towards the front of the projectile, this causes it to tend to "go that way" by that i mean it tends to not tumble like you've suggested as the lighter backing, or where you would "drill a hole" follows behind the heavier head of the bullet, and acts as a tail, like you would put on a kite, or i've used on large shells to either slow them down or increase accuracy by decreasing tumbling. a simple strip of fabric maybe 8inches long is good enough for a 2in diam. shell.

but any way back to the bullet design, i knew it have to be weighted by metal to be able to do any damage to a target and to have any kind of ballistic trajectory and hold up to my 2in sprinkler valve set up. so i went with 3/8in ball bearings, or slingshot ammo, very cheap, a box of 50 is like 3$. then for the tail i knew it would have to be rigid, and also be a perfect seal inside of a barrel, i looked long and hard but found that yellow electrical screw caps that you use to screw electrical wires together fit perfectly into a sch80 1/2in barrel. i don't remember the brand of these caps but i could figure it out easily. its like 10$ for a box of like 200 caps. you then simply hot glue or epoxy the ball bearings to the caps, and it literally is that easy they fly perfectly straight, leave perfect entry holes every time and are incredibly accurate for being smooth bore and being homemade ammo coming out of a home made 40$ sniper cannon

all in all you'll need a 1/2in sch80 pipe for a barrel: >2$

a box of yellow electrical caps: about 10$ for 200

and a case of slingshot ammo, (3/8in ball bearings): 50 for about 3$

and a hot glue gun or epoxy

i could make a video or try to post pics eventually by request. hope this explanation and bullet size works for you. i realize you were talking about a much larger bullet size but i gotta say i enjoy my sniper cannon a lot more then my behemoth of a potato cannon that is ridiculous to carry around takes forever to fill (by bike pump and air compressor).

not to but in here guys, but again im going to make an advertisement for the design of bullets i've dreamt up in the image of shotgun slugs like you suggested, and also with the budget of a jobless 16 year old in mind, a sabot works because of the high center of gravity towards the front of the projectile, this causes it to tend to "go that way" by that i mean it tends to not tumble like you've suggested as the lighter backing, or where you would "drill a hole" follows behind the heavier head of the bullet, and acts as a tail, like you would put on a kite, or i've used on large shells to either slow them down or increase accuracy by decreasing tumbling. a simple strip of fabric maybe 8inches long is good enough for a 2in diam. shell.

but any way back to the bullet design, i knew it have to be weighted by metal to be able to do any damage to a target and to have any kind of ballistic trajectory and hold up to my 2in sprinkler valve set up. so i went with 3/8in ball bearings, or slingshot ammo, very cheap, a box of 50 is like 3$. then for the tail i knew it would have to be rigid, and also be a perfect seal inside of a barrel, i looked long and hard but found that yellow electrical screw caps that you use to screw electrical wires together fit perfectly into a sch80 1/2in barrel. i don't remember the brand of these caps but i could figure it out easily. its like 10$ for a box of like 200 caps. you then simply hot glue or epoxy the ball bearings to the caps, and it literally is that easy they fly perfectly straight, leave perfect entry holes every time and are incredibly accurate for being smooth bore and being homemade ammo coming out of a home made 40$ sniper cannon

all in all you'll need a 1/2in sch80 pipe for a barrel: >2$

a box of yellow electrical caps: about 10$ for 200

and a case of slingshot ammo, (3/8in ball bearings): 50 for about 3$

and a hot glue gun or epoxy

i could make a video or try to post pics eventually by request. hope this explanation and bullet size works for you. i realize you were talking about a much larger bullet size but i gotta say i enjoy my sniper cannon a lot more then my behemoth of a potato cannon that is ridiculous to carry around takes forever to fill (by bike pump and air compressor).

- jackssmirkingrevenge

- Five Star General

- Posts: 26179

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 543 times

- Been thanked: 321 times

They look vaguely like the shells fired by the Anzio AnnieLeMaudit wrote:Like this picture (it is painted resin, about 1 inch long).

Some good discussion of cast projectiles here.

its like 10$ for a box of like 200 caps. you then simply hot glue or epoxy the ball bearings to the caps, and it literally is that easy they fly perfectly straight, leave perfect entry holes every time and are incredibly accurate for being smooth bore and being homemade ammo coming out of a home made 40$ sniper cannon

This concept of a tube that fits in the barrel and is closed and weighted at one end can be applied to any calibre, I had good results for a 3/4" barrel cutting 12 gram CO<sub>2</sub> capsules in half and pouring lead at one end.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Labtecpower

- Sergeant 3

- Posts: 1297

- Joined: Sat Feb 20, 2010 6:38 am

- Location: Pyongyang

- Has thanked: 5 times

- Been thanked: 13 times

What metal would be most suitable for a solid projectile?

Aluminium, steel or something in that direction?

Aluminium, steel or something in that direction?

Last edited by Labtecpower on Wed Mar 30, 2011 2:43 am, edited 1 time in total.

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

I think it is also against the rules.. You my wish to edit the post before a mod finds it.Labtecpower wrote:I guess it's cheating, but this is what I would like to do:

- Labtecpower

- Sergeant 3

- Posts: 1297

- Joined: Sat Feb 20, 2010 6:38 am

- Location: Pyongyang

- Has thanked: 5 times

- Been thanked: 13 times

Technician1002 wrote:I think it is also against the rules.. You my wish to edit the post before a mod finds it.Labtecpower wrote:I guess it's cheating, but this is what I would like to do:

I guess you were right