Difference between revisions of "Piston valve"

m (changed to wikicode) |

|||

| Line 1: | Line 1: | ||

| − | A '''piston valve''' is a [[pilot valve|pilot]] operated valve. It is very similar to a [[diaphragm valve]] in theory, but replaces it's flexible | + | A '''piston valve''' is a [[pilot valve|pilot]] operated valve. It is very similar to a [[diaphragm valve]] in theory, but replaces it's flexible diaphragm with a rigid cylinder. There are 2 varieties; barrel sealing and chamber sealing. |

== Construction, barrel sealing == | == Construction, barrel sealing == | ||

| Line 21: | Line 21: | ||

If your valve [[honking|honks]], it is probably a good idea to invest in a better [[pilot valve]]. | If your valve [[honking|honks]], it is probably a good idea to invest in a better [[pilot valve]]. | ||

[[category:valves]] | [[category:valves]] | ||

| + | |||

| + | |||

| + | the air is put into the gun from behind the piston. the piston is pushed into the rubber coupler, and it seals so no air can go out the barrel. | ||

| + | |||

| + | but air goes between the piston and pipe, and goes through the bottom of the tee, into the chambers. Okay, this is where the sprinkler valve comes in. Since there is air pressing on the front and back of the piston, but there is less surface on the front because of the seated barrel, the pressure on the back keeps it seated. | ||

| + | |||

| + | to fire, activate the solenoid, which vents the back of the piston, so there is much more more pressure pushing it on the front. This causes it to slam backwards, unseating the valve, and dumping huge amounts of air out the barrel at once. | ||

| + | |||

| + | this all actually happens instantaneously(instantly) at the instant you hit the button. This sprinkler valve vents | ||

Revision as of 23:19, 13 September 2006

A piston valve is a pilot operated valve. It is very similar to a diaphragm valve in theory, but replaces it's flexible diaphragm with a rigid cylinder. There are 2 varieties; barrel sealing and chamber sealing.

Construction, barrel sealing

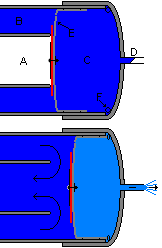

The piston is often a well fitting cup-shaped object, such as a endcap. To provide a sealing face, a piece of rubber is attached, typically with a bolt. Equalization is accomplished by simply allowing the air to leak past the piston and into the chamber. Some people will machine their own pistons, in which case they often build O-rings into them. With the O-rings, you need to make a small equalization hole; sometimes this is fancied up to be a homemade check valve.

Because a piston is heavier and harder than a diaphragm, and PVC is somewhat brittle, it is recommended that a bumper of sorts is built into your pilot volume. Common bumpers include heavy-duty rubber hose, and such. This is labeled "F" in the "use, barrel sealing" diagram.

These valves are often used on coaxials and over/unders. In an over/under, the valve is built in a "T" fitting. The barrel is put coaxially through one end, the pilot and piston are put in the opposite one, and a chamber is connected to the perpendicular opening with a 90° elbow.

Use, barrel sealing

Operation:

- Air is added by filling behind the piston (C).

- The piston (E) slides forwards, and seals against the barrel (A). (Alternatively, one can use a spring to move the piston forwards, which allows one to fill [slowly at first, to allow the pressure to equalize] from the chamber.)

- More air is added, and leaks around the piston (or through a small equalization hole) and into the chamber (B), filling it to the desired pressure.

- The pilot valve (D) behind the piston is opened, the pressure in the pilot volume (C) drops, and the higher pressure in the chamber area pushes the piston away from the barrel.

- The air flows around from the chamber, and into the barrel, propelling the projectile.

The performance of these valves can be calculated with the GGDT. If your valve honks, it is probably a good idea to invest in a better pilot valve.

the air is put into the gun from behind the piston. the piston is pushed into the rubber coupler, and it seals so no air can go out the barrel.

but air goes between the piston and pipe, and goes through the bottom of the tee, into the chambers. Okay, this is where the sprinkler valve comes in. Since there is air pressing on the front and back of the piston, but there is less surface on the front because of the seated barrel, the pressure on the back keeps it seated.

to fire, activate the solenoid, which vents the back of the piston, so there is much more more pressure pushing it on the front. This causes it to slam backwards, unseating the valve, and dumping huge amounts of air out the barrel at once.

this all actually happens instantaneously(instantly) at the instant you hit the button. This sprinkler valve vents