Difference between revisions of "Piston valve"

m (extra info) |

(+ chamber sealers) |

||

| Line 8: | Line 8: | ||

=== construction === | === construction === | ||

| − | The piston is often a well fitting cup-shaped object, such as a end cap. To provide a sealing face, a piece of rubber is attached, typically with a bolt. | + | The piston is often a well fitting cup-shaped object, such as a end cap. To provide a sealing face, a piece of rubber is attached, typically with a bolt. In the simplest case, equalization is accomplished by allowing the air to leak past the piston and into the chamber. Some people will machine their own pistons, in which case they often build [[O-ring]]s into them. With the O-rings, you need to make a small equalization hole; sometimes this is fancied up to be a homemade [[check valve]]. |

Because a piston is heavier and harder than a diaphragm, and PVC is somewhat brittle, it is recommended that a bumper of sorts is built into your pilot volume. Common bumpers include heavy-duty rubber hose, and such. This is labeled "'''F'''" in the "use, barrel sealing" diagram. | Because a piston is heavier and harder than a diaphragm, and PVC is somewhat brittle, it is recommended that a bumper of sorts is built into your pilot volume. Common bumpers include heavy-duty rubber hose, and such. This is labeled "'''F'''" in the "use, barrel sealing" diagram. | ||

| Line 23: | Line 23: | ||

#The air flows around from the chamber, and into the barrel, propelling the projectile. | #The air flows around from the chamber, and into the barrel, propelling the projectile. | ||

| − | -A | + | == Chamber sealing piston valve == |

| + | |||

| + | === construction === | ||

| + | |||

| + | The piston of a chamber-sealing piston valve has to seal on both the chamber port and to the pilot volume. This requires that the piston be machined with O-rings. A small equalization hole is required; sometimes this is fancied up to be a homemade [[check valve]]. | ||

| + | |||

| + | The piston is almost always housed in a "t" fitting. | ||

| + | |||

| + | Because a piston is heavier and harder than a diaphragm, and PVC is somewhat brittle, it is recommended that a bumper of sorts is built into your pilot volume. Common bumpers include heavy-duty rubber hose, and such. This is labeled "'''F'''" in the "use, chamber sealing sealing" diagram. | ||

| + | |||

| + | These valves are often used on [[over/under]]s, as the flow is already turned around 90<sup>o</sup>. | ||

| + | |||

| + | === Use === | ||

| + | [[Image:Wcspiston.PNG|frame|top=pressurized, bottom=firing]] | ||

| + | Operation: | ||

| + | #Air is added by filling behind the piston (C). | ||

| + | #The piston (E) slides forwards, and seals against the barrel (A). (Alternatively, one can use a spring to move the piston forwards, which allows one to fill [slowly at first, to allow the pressure to equalize] from the chamber.) | ||

| + | #More air is added, and leaks through the equalization hole in the piston and into the chamber (B), filling it to the desired pressure. | ||

| + | #The pilot valve (D) behind the piston is opened, the pressure in the [[pilot|pilot volume]] (C) drops, and the higher pressure in the chamber area pushes the piston away from the chamber. | ||

| + | #The air flows out of the chamber, and into the barrel, propelling the projectile. | ||

| + | |||

| + | == Common traits == | ||

| + | |||

| + | #The performance of these valves can be calculated with the [[GGDT]]. | ||

| + | #If your valve [[honking|honks]], it is probably a good idea to invest in a better [[pilot valve]], though this is more of a problem with barrel-sealing valves. | ||

| + | #In both cases, provided there is a good deal of space around the barrel, the full flow potential of the valve is realized when the piston has moved back 1/4th of the barrel's inside diameter. | ||

| + | #Pneumatic actuation is not mandatory; mechanical means can be used to air to hold the valve shut, rather than using the force of the air. | ||

| − | |||

| − | |||

[[category:valves]] | [[category:valves]] | ||

Revision as of 17:58, 26 July 2007

A piston valve is a pilot operated valve. It is very similar to a diaphragm valve in theory, but replaces it's flexible diaphragm with a rigid cylinder. There are 2 varieties; barrel sealing and chamber sealing.

Contents

Barrel sealing valve

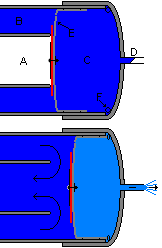

In a barrel sealing valve, the piston seals against the breech of the barrel. this is the most common piston valve design.

construction

The piston is often a well fitting cup-shaped object, such as a end cap. To provide a sealing face, a piece of rubber is attached, typically with a bolt. In the simplest case, equalization is accomplished by allowing the air to leak past the piston and into the chamber. Some people will machine their own pistons, in which case they often build O-rings into them. With the O-rings, you need to make a small equalization hole; sometimes this is fancied up to be a homemade check valve.

Because a piston is heavier and harder than a diaphragm, and PVC is somewhat brittle, it is recommended that a bumper of sorts is built into your pilot volume. Common bumpers include heavy-duty rubber hose, and such. This is labeled "F" in the "use, barrel sealing" diagram.

These valves are often used on coaxials and over/unders. In an over/under, the valve is built in a "T" fitting. The barrel is put co-axially through one end, the pilot and piston are put in the opposite one, and a chamber is connected to the perpendicular opening with a 90° elbow.

Use

Operation:

- Air is added by filling behind the piston (C).

- The piston (E) slides forwards, and seals against the barrel (A). (Alternatively, one can use a spring to move the piston forwards, which allows one to fill [slowly at first, to allow the pressure to equalize] from the chamber.)

- More air is added, and leaks around the piston (or through a small equalization hole) and into the chamber (B), filling it to the desired pressure.

- The pilot valve (D) behind the piston is opened, the pressure in the pilot volume (C) drops, and the higher pressure in the chamber area pushes the piston away from the barrel.

- The air flows around from the chamber, and into the barrel, propelling the projectile.

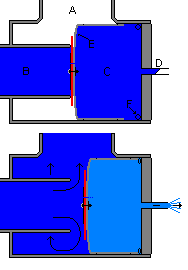

Chamber sealing piston valve

construction

The piston of a chamber-sealing piston valve has to seal on both the chamber port and to the pilot volume. This requires that the piston be machined with O-rings. A small equalization hole is required; sometimes this is fancied up to be a homemade check valve.

The piston is almost always housed in a "t" fitting.

Because a piston is heavier and harder than a diaphragm, and PVC is somewhat brittle, it is recommended that a bumper of sorts is built into your pilot volume. Common bumpers include heavy-duty rubber hose, and such. This is labeled "F" in the "use, chamber sealing sealing" diagram.

These valves are often used on over/unders, as the flow is already turned around 90o.

Use

Operation:

- Air is added by filling behind the piston (C).

- The piston (E) slides forwards, and seals against the barrel (A). (Alternatively, one can use a spring to move the piston forwards, which allows one to fill [slowly at first, to allow the pressure to equalize] from the chamber.)

- More air is added, and leaks through the equalization hole in the piston and into the chamber (B), filling it to the desired pressure.

- The pilot valve (D) behind the piston is opened, the pressure in the pilot volume (C) drops, and the higher pressure in the chamber area pushes the piston away from the chamber.

- The air flows out of the chamber, and into the barrel, propelling the projectile.

Common traits

- The performance of these valves can be calculated with the GGDT.

- If your valve honks, it is probably a good idea to invest in a better pilot valve, though this is more of a problem with barrel-sealing valves.

- In both cases, provided there is a good deal of space around the barrel, the full flow potential of the valve is realized when the piston has moved back 1/4th of the barrel's inside diameter.

- Pneumatic actuation is not mandatory; mechanical means can be used to air to hold the valve shut, rather than using the force of the air.