Difference between revisions of "Diaphragm valve"

m (spelling) |

m (added and fixed links) |

||

| Line 1: | Line 1: | ||

| − | A diaphragm valve is a [[ | + | A diaphragm valve is a [[pilot]] operated valve. It is very similar to a [[piston valve]] in theory, but replaces it's hard cylinder with a flexible diaphragm. |

== Construction == | == Construction == | ||

| − | The diaphragm is sometimes made of a simple piece of pliable material, for instance, thick neoprene (about 1/4" of the rubber is common) or a section of tupperware lid. However, there is often a problem with the material not being strong enough. In this case, the center of it is often reinforced with a pair of washers; one a bit bigger than the [[barrel]]'s diameter on the pilot side, and one a bit smaller than it on the barrel/chamber side. | + | The diaphragm is sometimes made of a simple piece of pliable material, for instance, thick [[neoprene ]](about 1/4" of the rubber is common) or a section of tupperware lid. However, there is often a problem with the material not being strong enough. In this case, the center of it is often reinforced with a pair of washers; one a bit bigger than the [[barrel]]'s diameter on the pilot side, and one a bit smaller than it on the barrel/[[chamber]] side. |

| − | These valves are often used on [[coaxial]]s and [[over/under]]s. In an over/under, the valve is built in a "T" fitting. The barrel is put coaxially through one end, the pilot and | + | These valves are often used on [[coaxial]]s and [[over/under]]s. In an over/under, the valve is built in a "T" fitting. The barrel is put coaxially through one end, the pilot and diaphragm are put in the opposite one, and a chamber is connected to the perpendicular opening with a 90° elbow. |

== Use == | == Use == | ||

| Line 11: | Line 11: | ||

Operation: | Operation: | ||

<ol><li>Air is added by filling behind the diaphragm (C). | <ol><li>Air is added by filling behind the diaphragm (C). | ||

| − | <li>The diaphragm (E) is flexed forwards, and seals against the barrel (A). (Alternatively, one can use a spring to move the piston forwards, which allows one to fill [slowly at first, to allow the pressure to equalize] from the chamber.) | + | <li>The diaphragm (E) is flexed forwards, and seals against the barrel (A). (Alternatively, one can use a spring to move the piston forwards, which allows one to fill [slowly at first, to allow the [[pressure]] to equalize] from the chamber.) |

<li>More air is added, and leaks around the diaphragm (or through a small equalization hole) and into the chamber (B), filling it to the desired pressure. | <li>More air is added, and leaks around the diaphragm (or through a small equalization hole) and into the chamber (B), filling it to the desired pressure. | ||

| − | <li>The pilot valve (D) behind the diaphragm is opened, the pressure in the | + | <li>The [[pilot valve]] (D) behind the diaphragm is opened, the pressure in the pilot volume (C) drops, and the higher pressure in the chamber area pushes the diaphragm away from the barrel. |

<li>The air flows around from the chamber, and into the barrel, propelling the projectile.</ol> | <li>The air flows around from the chamber, and into the barrel, propelling the projectile.</ol> | ||

| − | The performance of these valves can be calculated with | + | The performance of these valves can be calculated with [[GGDT]]. |

| − | If your valve [[honking|honks]], it is probably a good idea to invest in a better | + | If your valve [[honking|honks]], it is probably a good idea to invest in a better pilot valve. |

[[category:valves]] | [[category:valves]] | ||

Revision as of 12:28, 1 June 2008

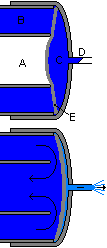

A diaphragm valve is a pilot operated valve. It is very similar to a piston valve in theory, but replaces it's hard cylinder with a flexible diaphragm.

Construction

The diaphragm is sometimes made of a simple piece of pliable material, for instance, thick neoprene (about 1/4" of the rubber is common) or a section of tupperware lid. However, there is often a problem with the material not being strong enough. In this case, the center of it is often reinforced with a pair of washers; one a bit bigger than the barrel's diameter on the pilot side, and one a bit smaller than it on the barrel/chamber side.

These valves are often used on coaxials and over/unders. In an over/under, the valve is built in a "T" fitting. The barrel is put coaxially through one end, the pilot and diaphragm are put in the opposite one, and a chamber is connected to the perpendicular opening with a 90° elbow.

Use

Operation:

- Air is added by filling behind the diaphragm (C).

- The diaphragm (E) is flexed forwards, and seals against the barrel (A). (Alternatively, one can use a spring to move the piston forwards, which allows one to fill [slowly at first, to allow the pressure to equalize] from the chamber.)

- More air is added, and leaks around the diaphragm (or through a small equalization hole) and into the chamber (B), filling it to the desired pressure.

- The pilot valve (D) behind the diaphragm is opened, the pressure in the pilot volume (C) drops, and the higher pressure in the chamber area pushes the diaphragm away from the barrel.

- The air flows around from the chamber, and into the barrel, propelling the projectile.

The performance of these valves can be calculated with GGDT. If your valve honks, it is probably a good idea to invest in a better pilot valve.