Piston valve

A piston valve is a pilot opperated valve. It is very similar to a diaphragm valve in therory, but replaces it's flexable diaphram with a hard cylinder. There are 2 varieties; barrel sealing and chamber sealing.

Construction, barrel sealing

The piston is often a well fitting cup-shaped object, such as a endcap. To provide a sealing face, a peice of rubber is attached, typicaly with a bolt. Equilization is accomplished by simply allowing the air to leak past the piston and into the chamber. Some people will machein their own pistons, in which case they often build O-rings into them. With the O-rings, you need to make a small equilization hole; sometimes this is fancied up to be a homemade check valve.

Because a piston is heavier and harder than a diaphram, and PVC is somewhat brittle, it is recomended that a bumper of sorts is built into your pilot volume. Common bumpers include heavy-duty rubber hose, and such. This is labled "F" in the "use, barrel sealing" diagram.

These valves are often used on coaxials and over/unders. In an over/under, the valve is built in a "T" fitting. The barrel is put coaxial through one end, the pilot and piston are put in the opposite one, and a chamber is conected to the perpendicular opening with a 90° elbow.

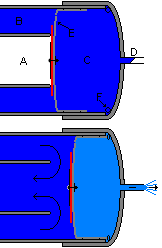

Use, barrel sealing

Opperation:

- Air is added by filling behind the piston (C).

- The piston (E) slides forwards, and seals on the barrel (A).

- More air is added, and leaks around the piston (or through a small equilization hole) and into the chamber (B), filling it to the desired pressure.

- The pilot valve (D) behind the piston is oppened, the pressure in the pilot volume (C) drops, and the higher pressure in the chamber area pushes the diaphram off the barrel.

- The air flows around from the chamber, and into the barrel, propelling the projectile.

The preformance of these valves can be calculated with the GGDT. If your valve honks, it is probably a good idea to invest in a better pilot valve.