Page 1 of 1

Copper soldering and joint construction question

Posted: Sat Mar 08, 2008 4:01 am

by c9d

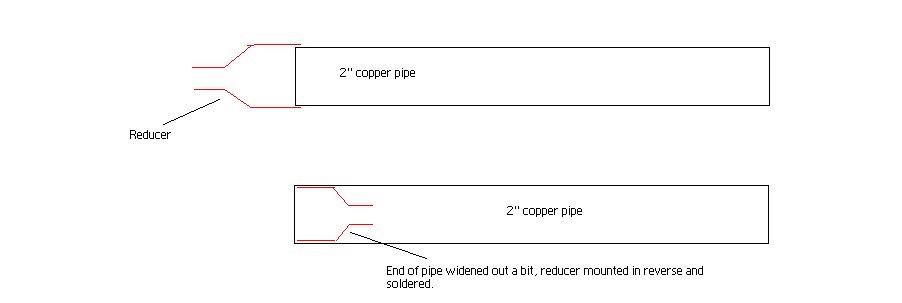

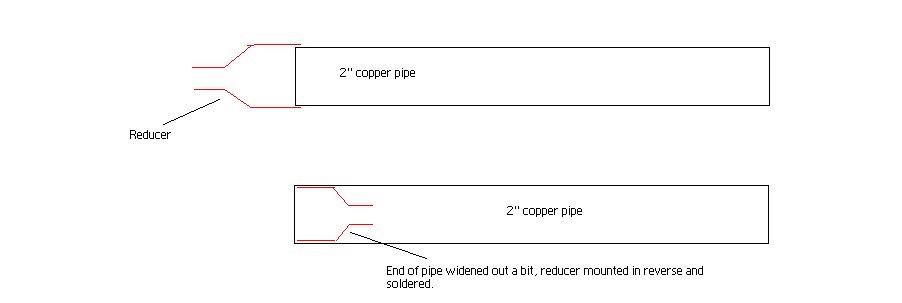

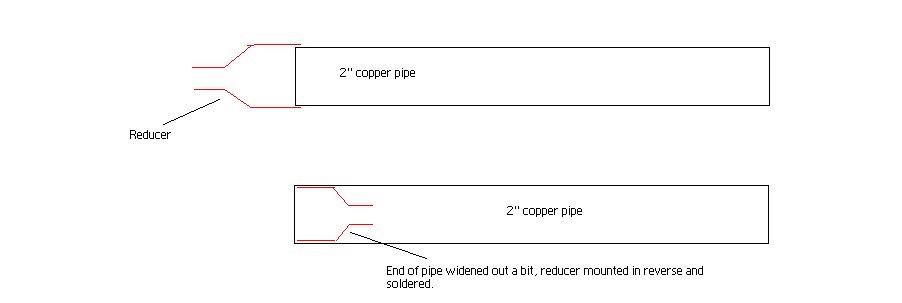

I was wondering if it was possible to take a 2" hard copper pipe, widen the end out a bit, and insert a reducer the opposite way, then solder it together? Or expand a smaller reducer to fit in an unmolested piece of 2" copper pipe?

This is a rough sketch of what I would like to accomplish:

Posted: Sat Mar 08, 2008 4:19 am

by MrCrowley

I seriously doubt copper can be modified so heavily.

Your best bet would be finding next size reducer and possibly grinding it down a bit if it's too big. If it's too small you'd have to find another way.

What exactly are you trying to accomplish?

Posted: Sat Mar 08, 2008 7:37 am

by psycix

Uhmmmm

Epoxy casting?

Posted: Sat Mar 08, 2008 8:00 am

by Hawkeye

It is called Swaging and is possible with the right swaging tool. I don't think people generally swage larger diameter pipe though.

I do that set up all the time but I use a coupler and a bushing reducer which goes inside the coupler. Then you can just put it in backwards.

You should be able to get bushing reducers as well as the external fittings in a good supply store.

You could always modify your set-up if you can't find exactly what you need.

For example you might have to put a reducer over the end of the 2" pipe and then put a smaller bushing reducer in the tapered end, backwards.

Posted: Sat Mar 08, 2008 8:16 am

by Ragnarok

Copperman to the rescue!!!

Based on my experiences with copper, I don't think this is a particularly good solution, you'll risk either a serious weakening of the pipe if you don't know what you're doing, or tearing the pipe - especially with hard pipe. You' shouldn't try this with more than semi-rigid pipe.

So instead, I'd recommend doing what Hawkeye suggested, and getting a 2" coupler, and a 2" male to x" female reducer.

Put the 2" male to x" female reducer nose into the 2" coupler, then solder the 2" pipe into the other end of the 2" coupler.