Page 1 of 2

Blow forward barrel

Posted: Sun Mar 27, 2011 9:50 pm

by Lockednloaded

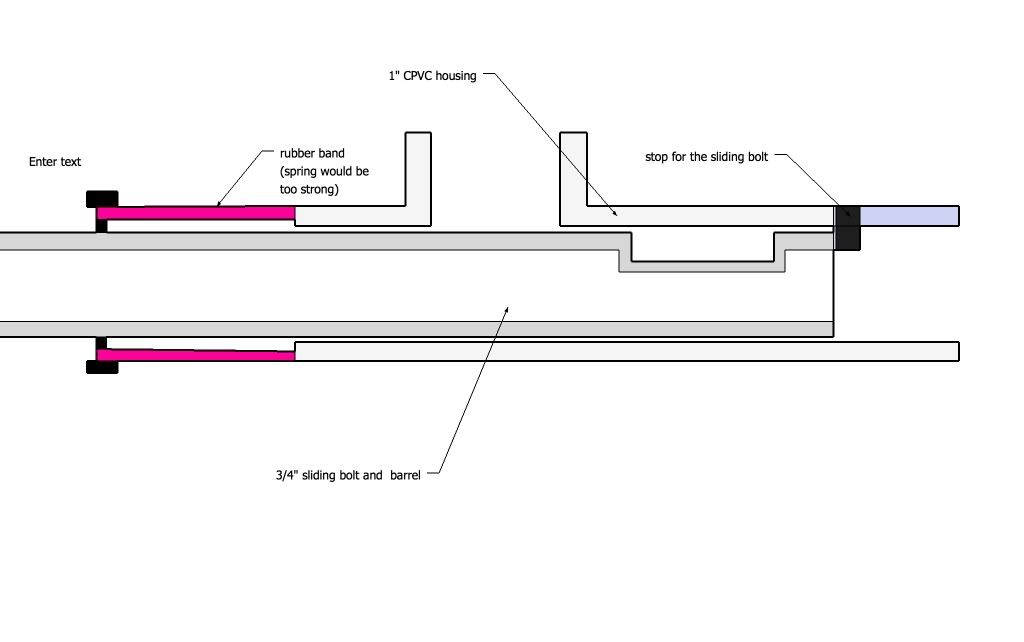

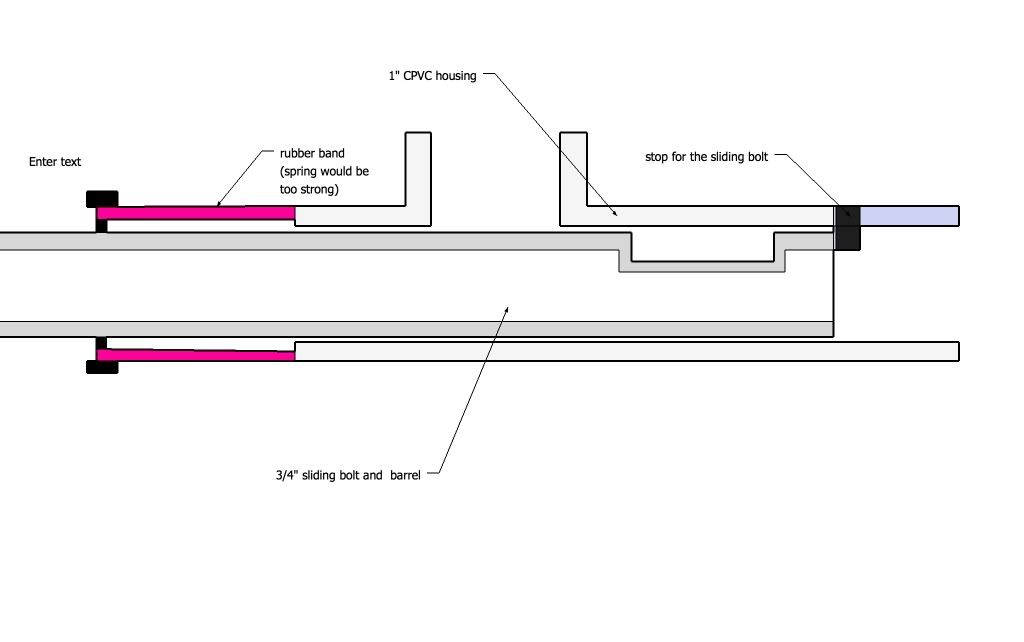

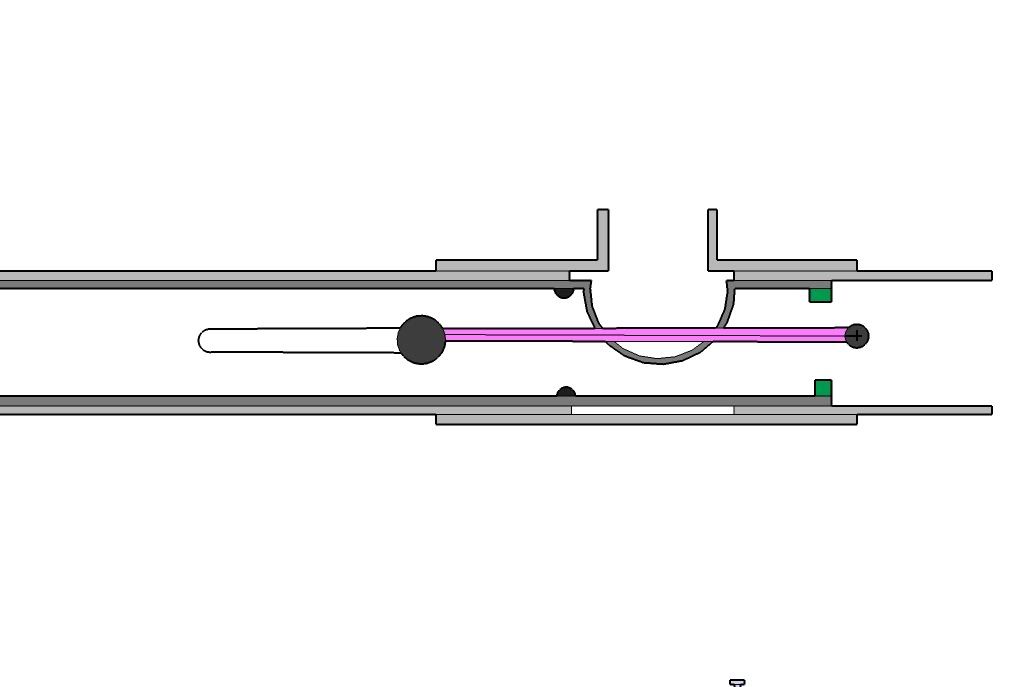

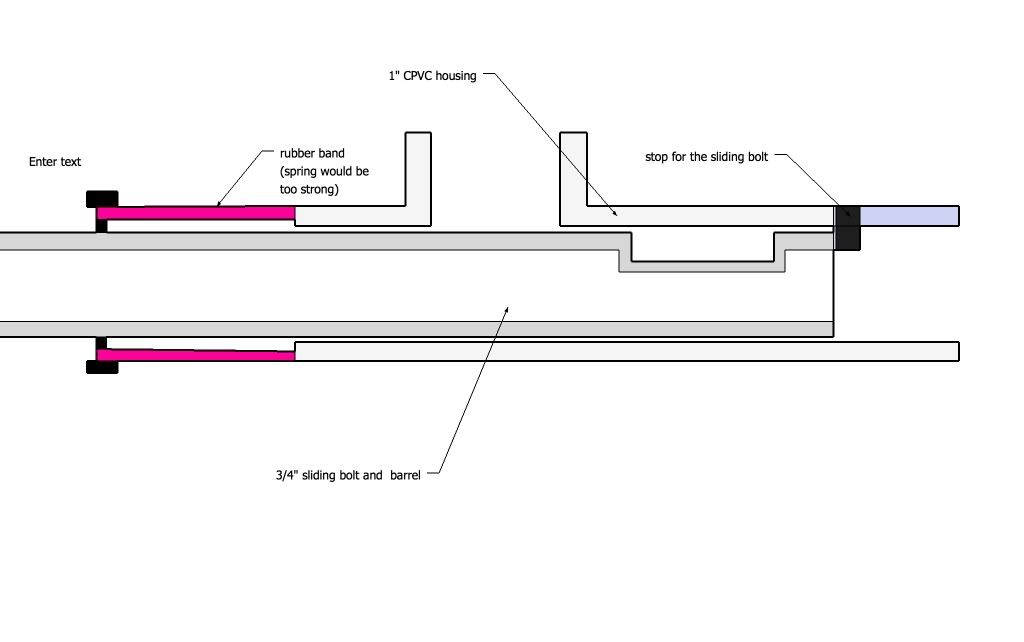

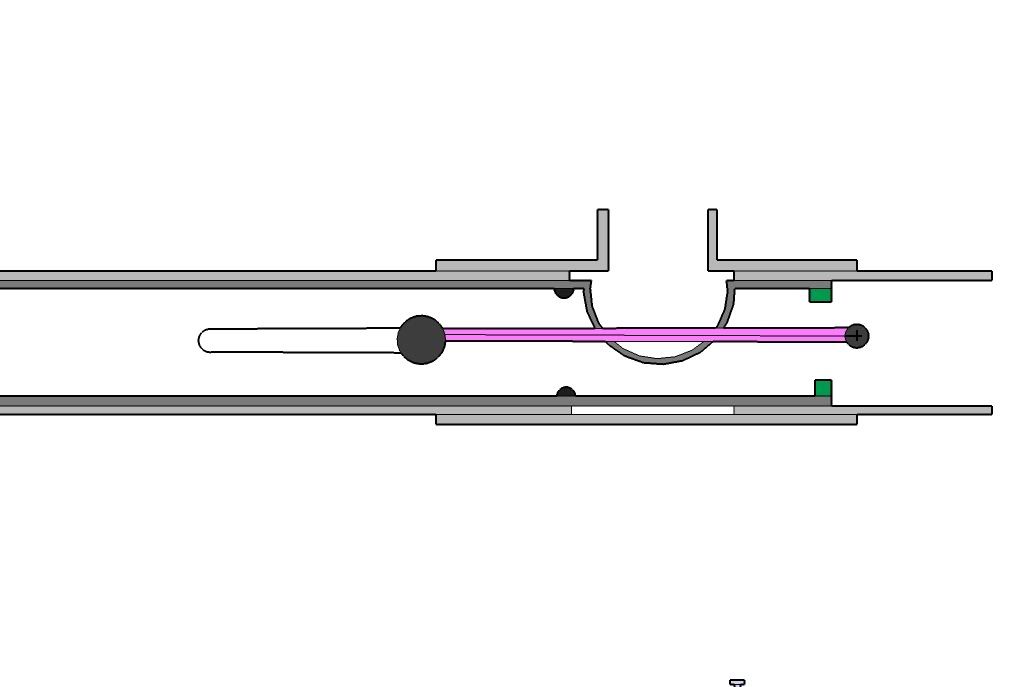

Well I've finally put together the blow forward barrel mechanism, but despite it looking totally awesome when it cycles, Its having a lot of problems. I made it with out o-rings, just the fairly snug fit between 3/4" and 1" cpvc. The barrel blows forward everytime, but for some reason it needs an air tight mag to feed ammo. I want to be able to use a hopper for it, but that won't work with the current design. Any suggestions?

Posted: Sun Mar 27, 2011 10:00 pm

by clemsonguy1125

Not sure about your problem but what causes the barrel to blow forward, would air just come straight out the barrel

Posted: Sun Mar 27, 2011 10:06 pm

by JDP12

take a look at JSR's work with blow forward..

he put a stop at the end of the bolt housing, so that no air went through the bolt until a round was in. So basically, the bolt moved down the stop, with no air getting through, until the bolt cleared the stop, then air was free to go down the bolt.

Posted: Sun Mar 27, 2011 10:08 pm

by clemsonguy1125

His sketch doesn't show one end of the barrel being blocked though. I don't know if you were talking to me or him.

Posted: Sun Mar 27, 2011 10:08 pm

by Gaderelguitarist

what causes the barrel to blow forward, would air just come straight out the barrel

I'm not sure exactly what thread it was in the past, but someone built a blow forward bolt with no more than the edge surface area of the pipe wall for the air to act on and it worked.

Air is probably escaping through your mag port and preventing a full cycle of the bolt. At least thats how I see it.

Posted: Sun Mar 27, 2011 10:12 pm

by Lockednloaded

There is a small flow restriction at the beginning of the barrel before the mag port that give air some surface area to push on. The diagram is a very old one, not very similar to the actual design, but same concept. I'll have pictures of the true setup tomorrow. The bolt cycles a full three inches forward, so I may just need some o-rings, but I really hope I don't

Posted: Sun Mar 27, 2011 10:14 pm

by Gaderelguitarist

I would think an o ring before and after the mag port would help.

Posted: Sun Mar 27, 2011 10:29 pm

by Lockednloaded

Thats going to be tough, it'll have to be extremely low friction without deep grooves...

The actual design I've been using, I hope everything's clear

Posted: Sun Mar 27, 2011 11:35 pm

by POLAND_SPUD

guns are just like women... they operate best when loaded from behind

that's just my personal opinion... also moving barrels are not always the best idea

Posted: Mon Mar 28, 2011 6:30 pm

by Lockednloaded

There are better ways that have been sucessful, but I really like the blow-forward action. Think of it like JSR and his cartridges. He wanted flying brass, I want a gun that cycles like a bofors

Posted: Mon Mar 28, 2011 7:03 pm

by Gaderelguitarist

Is that design to scale? or roughly so?

It's easy enough to understand. I just can't think of a reason why your mag doesn't feed when not airtight.

Posted: Mon Mar 28, 2011 7:29 pm

by Lockednloaded

roughly to scale. The mag feeds, just ammo can make it past the detent. I need the detent to aim downwards, so its staying

Posted: Mon Mar 28, 2011 7:33 pm

by Gun Freak

Why don't you just use a smaller detent?

Posted: Mon Mar 28, 2011 7:46 pm

by Lockednloaded

Its two pieces of electrical tape right now, I really can get much smaller. Also when I tested it without the detent, the tee mag was blown off and it double fed

Posted: Mon Mar 28, 2011 8:07 pm

by Gaderelguitarist

At rest, is the mag port in the barrel to the left or right of the hole in the tee?

Nevermind

I took another look at the diagram. I think you should be fine with putting an o-ring in the Tee itself on the right side of the diagram. This would seal off your mag and prevent your problem. Make sure it's sized to the inner diameter of the pipe it's in rather than the barrel though since it will ride against your port.