Agreed!jackssmirkingrevenge wrote: Sometimes you need an arsehole to say the things everyone else is too polite or tactful or afraid to say, it's a necessary evil.

"Offtopic-posts-topic" NSFW

- Gippeto

- First Sergeant 3

- Posts: 2504

- Joined: Sat Jan 19, 2008 10:14 am

- Location: Soon to be socialist shit hole.

- Has thanked: 2 times

- Been thanked: 17 times

"It could be that the purpose of your life is to serve as a warning to others" – unknown

Liberalism is a mental disorder, reality is it's cure.

Liberalism is a mental disorder, reality is it's cure.

- mattyzip77

- Sergeant 3

- Posts: 1249

- Joined: Tue Jun 28, 2011 12:22 pm

- Location: Taxachusetts

I love being that guy!!!!Gippeto wrote:Agreed!jackssmirkingrevenge wrote: Sometimes you need an arsehole to say the things everyone else is too polite or tactful or afraid to say, it's a necessary evil.

Go Bruins!!!!

- killerbanjo

- Specialist 2

- Posts: 245

- Joined: Fri Jun 18, 2010 6:56 pm

So I have been doing lots of freediving recently and I really want a depth gauge but a cannot afford one  So I have been thinking how to make one...

So I have been thinking how to make one...

This is what I got: Buy a cheap pressure gauge, epoxy a small bit of tube onto the threads and then epoxy a tire valve into the tube. Then fill through the tire valve until 2 bar is in it.

When going underwater when at 33ft it should reduce the gauge to 1bar and 66ft to 0 bar. Im not diving deeper than that at the moment... The only thing is... is will the gauge work underwater? Or will it just cave in?

This is what I got: Buy a cheap pressure gauge, epoxy a small bit of tube onto the threads and then epoxy a tire valve into the tube. Then fill through the tire valve until 2 bar is in it.

When going underwater when at 33ft it should reduce the gauge to 1bar and 66ft to 0 bar. Im not diving deeper than that at the moment... The only thing is... is will the gauge work underwater? Or will it just cave in?

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

if it's sealed (the gauge) then I guess it should work underwater with no modifications

Children are the future

unless we stop them now

unless we stop them now

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

I don't get the physics here.

If you have 2 bar in an incompressible tube, why should this pressure reduce as you go deeper?

If you have 2 bar in an incompressible tube, why should this pressure reduce as you go deeper?

hectmarr wrote:You have to make many weapons, because this field is long and short life

- MrCrowley

- Moderator

- Posts: 10078

- Joined: Fri Jun 23, 2006 10:42 pm

- Location: Auckland, New Zealand

- Been thanked: 3 times

I was left wondering the same thing all day. Can't you just use a precise gauge that is open to the water? My thinking is that it's similar to gauges used in potable water supplies; 10m deep = 1 bar of water pressure.

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

That would corrode beyond repair on its first use.MrCrowley wrote:I was left wondering the same thing all day. Can't you just use a precise gauge that is open to the water?

Here's another thought, why not connect the gauge to the nozzle end of a syringe, and cut down the plunger so that just enough is left to keep the seal steady? That way as you go down the pressure increase will compress the plunger, increasing the reading on the gauge. You could leave out the gauge altogether and just mark pressure increments on the syringe body.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- pneumaticcannons

- Specialist 3

- Posts: 392

- Joined: Sat Oct 30, 2010 9:45 am

- Location: shite country in asia

- Contact:

unless that gauge was sealed, and the hardware store type aren't, the needle wouldn't move at all because the water pressure would be pressing on the <strike>little piston</strike> bourdon tube inside of the gauge and on the syringe essentially canceling each other out. I actually like the original Idea though you might want to drill some ports in the steel casing of the gauge so the pressure doesn't crush the glass because it couldn't equalize fast enough.why not connect the gauge to the nozzle end of a syringe, and cut down the plunger so that just enough is left to keep the seal steady? That way as you go down the pressure increase will compress the plunger, increasing the reading on the gauge.

Last edited by pneumaticcannons on Wed Sep 12, 2012 6:45 am, edited 1 time in total.

ramicaza <- My Youtube Channel

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

That doesn't sound right because they have different areas...pneumaticcannons wrote:unless that gauge was sealed, and the hardware store type aren't, the needle wouldn't move at all because the water pressure would be pressing on the little piston inside of the gauge and on the syringe essentially canceling each other out.

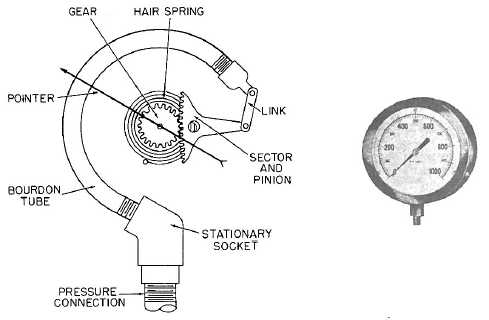

Also, what "little piston"? This is what most air gauges look like inside:

hectmarr wrote:You have to make many weapons, because this field is long and short life

- pneumaticcannons

- Specialist 3

- Posts: 392

- Joined: Sat Oct 30, 2010 9:45 am

- Location: shite country in asia

- Contact:

Forgot about that little tidbit, lolThat doesn't sound right because they have different areas...

But yea you were right. Though the needle movement would be minimal because water pressure still is pressing against the bourdon tube... unless you used a really wide syringe.

I had no idea that it is actually called a "bourdon tube". I learned something todayAlso, what "little piston"?

ramicaza <- My Youtube Channel

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

My suggestion assumed the gauge was sealed... I would just encase the gauge in a block of epoxy et voilapneumaticcannons wrote:Though the needle movement would be minimal because water pressure still is pressing against the bourdon tube... unless you used a really wide syringe.

hectmarr wrote:You have to make many weapons, because this field is long and short life

- Crna Legija

- First Sergeant 2

- Posts: 2333

- Joined: Sun Jul 20, 2008 5:14 am

- Location: australia

tie 20 meters of rope to a float put a not in the rope ever meter or so and bam you got a depth gauge!

'' To alcohol... The cause of, and solution to, all of life's problems.”

--Homer Simpson

Add me on ps3: wannafuk, 8/11/11 cant wait

--Homer Simpson

Add me on ps3: wannafuk, 8/11/11 cant wait

- killerbanjo

- Specialist 2

- Posts: 245

- Joined: Fri Jun 18, 2010 6:56 pm

Thinking about it your quite right... I think i would have to have a piston.jackssmirkingrevenge wrote:I don't get the physics here.

If you have 2 bar in an incompressible tube, why should this pressure reduce as you go deeper?

EDIT: Boom http://www.instructables.com/id/Diving-Depth-Gauge/

Read your full post and you already mentioned it :V Nice one

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

boom!!!! hehe exactly what I was thinking of!

hectmarr wrote:You have to make many weapons, because this field is long and short life

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

[youtube][/youtube]omg they are awesome

Children are the future

unless we stop them now

unless we stop them now