Page 1 of 1

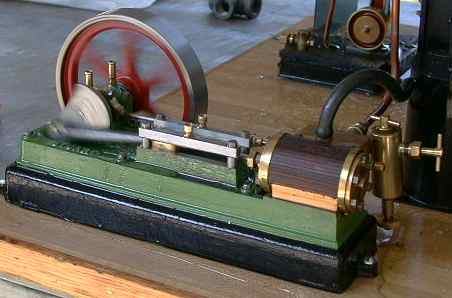

my steam engine doble acting slide valve

Posted: Fri Jan 30, 2009 6:34 pm

by maggotman

here are some pictures of my steam engine i made only a pillar drill was used to make this along with some files and a hack saw and allot of elbow grease the flywheel is a 1 inch section of 220mm bar stock i found at collage i started turing it down but havent had time to finish it i foolishly broke it buy trying to use it at 240psi and it bent the bar coming out of the cilender

it runs nice between 5 and 70 psi and about 200rpm

pleas comment ask questions suggest improvements

Posted: Fri Jan 30, 2009 8:14 pm

by Sticky_Tape

Wow crude but if it works

I suggest making the flywhell smaller so the engine puts less work into spining that getting it to go faster or maybe just drill holes to make it lighter while keeping most of the weight around the perimeter.

Posted: Fri Jan 30, 2009 8:25 pm

by maggotman

i did have a smaller fly wheel on it but i prefer this one it sooths everything out and puts a nice load on while increasing rpms

before this i made an osilating one that got to 3 k then a air hogs style that got to 12k (yes 12000 rpm) my tutor said that it was to dangerous so i decided to make this type of engine suited to lo rpms

Posted: Fri Jan 30, 2009 8:36 pm

by CasinoVanart

Yeah can you imagine a something breaking loose at 12000rpm? Not pretty!

I would like to make a real small one and use it to power a tatto gun, how steampunk would that be!! Nice work too with limited tools, it could certainly look better but you were limited, good work.

Have you any links to basic steam engine designs?

Posted: Sat Jan 31, 2009 2:27 am

by Daltonultra

You need a rod guide for your cylinder rod. If you look here, the joint where the cylinder rod bolts to the connecting rod is supported so it can't flex when the crank is at the top or bottom of it's revolution, where the angular stress i highest. All you'd need is a couple bars and some spacers.

Posted: Sat Jan 31, 2009 5:55 am

by maggotman

i was planing to make some cross head bearings but the idea of more filing and sawing made me take a short cut i didn not make the piston and barrel

im thinning about make ing a bigger one with a 70mm piston and a 90mm stroke i am planing to make parts for it in collage and hopefully a reversing link i will be using be using cross head bearings on this tho

Posted: Sat Jan 31, 2009 6:45 am

by inonickname

I made my air/Co2 engine on a lathe, and glad for it. I've reworked it to cope with 200+ psi, but I need to make a watercooling system.

Bit messy, but nice work

Posted: Sat Jan 31, 2009 2:05 pm

by maggotman

wahy would you nee water copling if thers that muck friction you have a problem and the gas naturally cools the motor buy expanding and absorbing the heat

Posted: Mon Feb 02, 2009 11:20 am

by psycix

Nice! Now reverse its use and make a compressor out of it!

Could it take moar then 70 psi?

Posted: Mon Feb 02, 2009 5:40 pm

by maggotman

i would not work as a compressor becuse it used a slide valve that is seald buy incoming air pressure