As a small side question, how much will this kind of heat affect the safe working pressure of the pipe?

thanks

Reference http://www.welding-technology ... razing.htmA typical alloy contains 45% Ag, 15% Cu., 16% Zn and 24% Cd and it has melting point and flow point 607°C and 618°C respectively.

jackssmirkingrevenge wrote:I wonder... if you put flammable vapours inside a lady... could you get her to diesel?

POLAND_SPUD wrote:Anything is possible with the proper 3-way valve.

JB weld or devcon plastic steelAlster370 wrote:Im not really sure how to join some pieces of copper pipe together because I fear the joining material may melt when the project is tested. Without revealing anything, the project will involve heating a section of copper pipe to rather high temperatures (350C+) and I think that solder & epoxy will both fail under those kind of temperatures. What other options do I have? Unfortunately I don't have a welder, but I have a powerful blowtorch on hand.

As a small side question, how much will this kind of heat affect the safe working pressure of the pipe?

thanks

I thought this might be a problem. Thankfully I know where I can get some work done with a proper torch.The problem with heating the copper with a blow torch is the excess air drawn through the flame. This oxidises the copper and makes porous leaky filler. The industry standard for refrigeration work is silver brazing solder with an oxy torch with the oxygen set neutral to low (carborizing flame) with a small feather inside the flame envelope. The area inside the feather is oxygen deficient and provides shielding gas to protect the joint from oxidisation. It will actually remove the oxide from the pipe. When silver brazing you can see the pipe start to glow then the oxide burn off leaving shiny copper ready for a good braze job without using flux. Since you need temperature resistance to 350 C and the silver brazing is done at about 600C, you should be OK.

I would highly recommend finding someone with the proper torch. Trying to use air will result in oxidised copper that the filler will not stick to, but roll off instead.

Miniature steam cannon, just as a side project until I have finished my planning for my upcoming coaxial. Probably not too long, im hoping high temperature will boil the water fairly quickly. It will be small because I want a relatively short firing time and the only way to do that easily is with a small chamber. Steam takes up ~1700 times more volume than water, so even a small chamber of 20ml can produce half decent pressures.What in gods name are you doing that it is going to be that hot?? How long of a period will it be that hot??? a second, a few seconds????

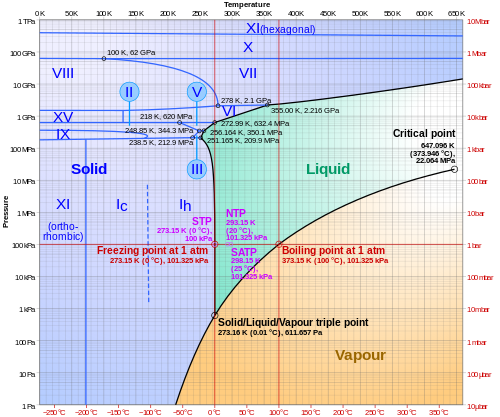

This particular setup will have a burst disk, mainly to make sure the pressure doesn't build up too high, But also to maximize the performance.Water at 350C would be at about 100 Bar pressure.

So ideally I need my copper to be type K (446psi rating at 400f W 1/2D)Be aware that brazing temps will anneal the copper (assuming it's drawn)...lowering the rating of the tube.

You need to be a member in order to post a reply

Not a member? register to join our community

Members can start their own topics & subscribe to topics

It’s free and only takes a minute