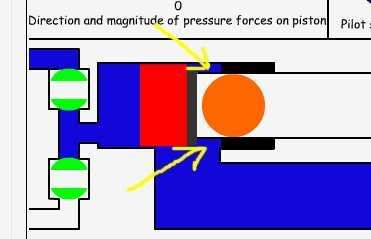

Im a little short on fittings so what ive done is put a shrader valve on to a 3/4 blank for the fill/trigger and piped this onto the blow gun which has another shrader valve at the other end. Both of the valves on these shraders have been removed.

For the piston ive used a wooden dowel which fits perfectly in the 3/4 pipe, it has some rubber from a bike tube screwed on with a washer.

Originally i did not have the straight placed behind the tee but i felt it was needed to try get a better suction on the piston when firing the blow gun.

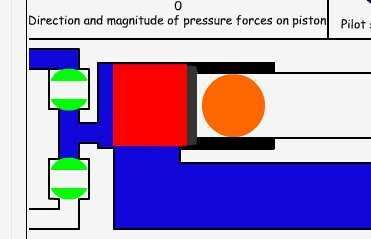

My problem is, it fills with air fine but when i use the blow gun it just leaks out all of th air and does not move the piston (which moves quite freely when not under pressure)

When its under pressure i tried physically pushing it from the barrel side and noticed it takes a lot of force to release the air.

Can anybody shed some light on where in going wrong??

Thanks in advance