Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

Easterbunny

- Private

- Posts: 19

- Joined: Wed Jan 02, 2008 1:24 pm

Thu Jan 01, 2009 7:31 pm

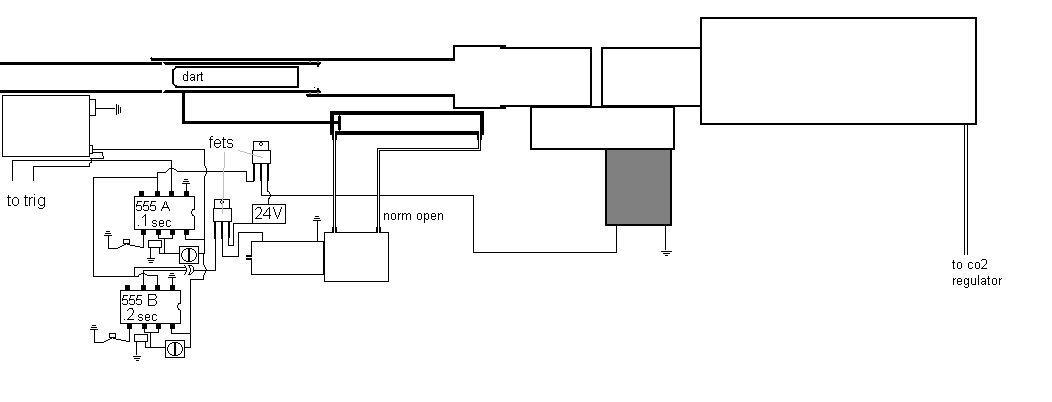

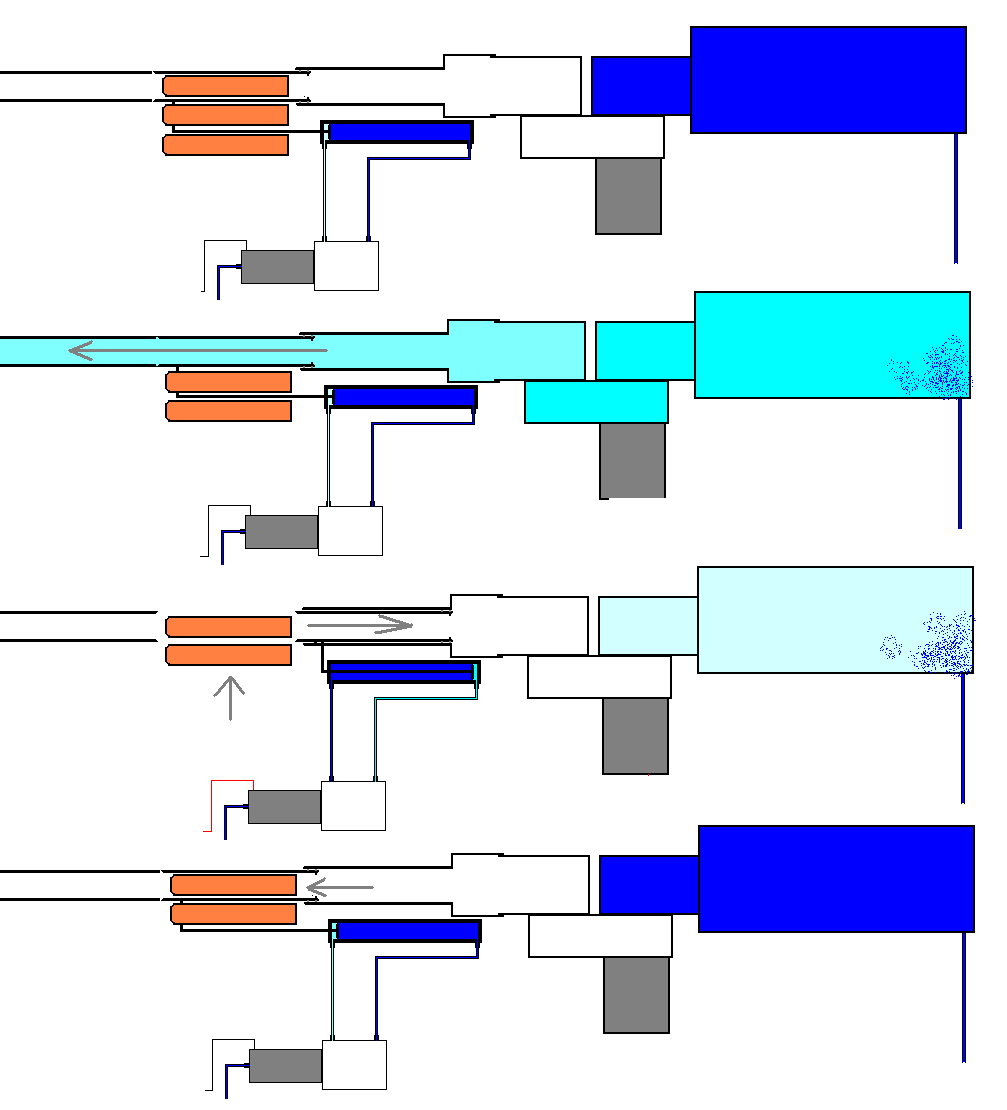

Looking around I have seen many wonderfully complex mechanical answers to the semi auto problem in spudding. After having several nerf wars with friends I have decided to make my own solution that I think would work best. It electronically actuates the sprinkler valve and a piston connected to the bolt. It works with two 555 timer chips and a 4 gate XOR chip. The idea is that at the trigger pull a negative going pulse is sent to both chips. Timer A opens the solenoid and closes it. The signal is split to the valve and to the first input of a XOR gate. Timer B’s pulse width is twice that of A and it’s signal goes to the other input of the XOR chip, this causes that when both chips outputting a signal the XOR sends nothing, but after timer A is done timer B’s signal is let through thus opening the bolt and allowing another round into the breech only when the sprinkler valve closes. And when the signal ends and 2 way valve switches to the normally open end and closes the bolt.

The electronics have there own 9V battery and the solenoid’s have a separate 24V battery pack (Three 9V wired in line) that is where the fet’s come in. the fets allow the higher voltage through when they receive the timer’s signal.

I’m goanna make my friends poop them selves when they see this

-

Attachments

-

- nerf semi system.PNG (15.45 KiB) Viewed 3322 times

-

- nerf semi system firing.PNG (35.34 KiB) Viewed 3322 times

-

TurboSuper

- Corporal 5

- Posts: 986

- Joined: Thu Jun 16, 2005 1:44 pm

- Been thanked: 1 time

Thu Jan 01, 2009 7:40 pm

Just FYI, you can get a 556, which is two 555 timers in one package.

Sounds like a solid plan- I was considering an electronic semi-auto system for a spudgun too a while back.

"If at first you dont succeed, then skydiving is not for you" - Darwin Awards

-

POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

Thu Jan 01, 2009 8:22 pm

well it seems ok but this design requires you to use an additional valve just to operate the air cylinder...

what's the point in using electronic stuff when you can achieve the same with an air cylinder hooked up to a chamber ?(of corse assuming that you can constrict the flow into the chamber enough to give time for the bolt to load new ammo before the pressure increases again)

do springkler vales have some characteristic that makes you use electronics and timing circuts ?

I don't see any reason why it wouldn't work but I would like to know why do you make it overly complicated.. there are lots of things that can go wrong even in the simplest semis... there is no point in increasing likelyhood of this

Children are the future

unless we stop them now

-

Hotwired

- First Sergeant 3

- Posts: 2599

- Joined: Fri Oct 13, 2006 5:51 am

- Location: UK

Thu Jan 01, 2009 9:17 pm

Hm?

I don't see a problem with mixing electronics with pneumatics. At the very least I'd quite like a trigger for high pressure that doesn't need a fair bit of hauling on to shift while still using one finger. Unfortunately as the kind of electronic (read: solenoid) valves that do directly work with high pressure tend to have crap flow or amazing prices it might need some kind of valve cascade to trip the main pneumatic valve.

I might be missing something but I do know you need a 5 port spool valve not a 3 port one to control one pneumatic cylinder, looks like you're using a 3 port one in the diagram.

If you can build it it would be fun to see in action.

-

Easterbunny

- Private

- Posts: 19

- Joined: Wed Jan 02, 2008 1:24 pm

Thu Jan 01, 2009 9:22 pm

the sprinkler valve has something called a solenoid. this is a spring loaded plunger that is pulled up by a electro magnet, it is like a electric pilot valve. when the plunger is pulled up a small leak of air pulls a rubber diaphragm up, and in doing so it creates a larger opening to allow air to pass through instead of the small opening of the solenoid. to your second question, because with the electronics I can easily adjust the timing of the valves, whereas in a mechanical semi you would have to rebuild it or something much more major than just turning a trim pot. (also if something dose go wrong with the electronics I have a engineer from Motorola to help me (dad))

P.S. and electronics are CHEAP (30 cents for a 555 chip)

http://en.wikipedia.org/wiki/Solenoid_valve

http://www.goldmine-elec-products.com/p ... ber=A10268

Last edited by

Easterbunny on Thu Jan 01, 2009 10:12 pm, edited 1 time in total.

-

POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

Thu Jan 01, 2009 10:03 pm

it's nice that you provided a definition of a solenoid valve

but I suppose that hotwired was reffering specifically to high pressures... I understand that you want to use PVC becasue metal sprinkler valves are very expensive (which proves his point) so it doesn't matter any way

the most important question you need to answer is -> do I really need electronics ??

have a look here ->

http://www.spudfiles.com/forums/i-has-s ... 16872.html

it works ok and I have never had any problems with timing... friction and inertia does it for me... when the bolt moves to load new ammo what was in the barrel is already gone....

I plan to add to it a simple circut that would send electric signals at predefined intervals to the solenoid to turn it into a fullauto... I'll contact your dad then, ok??

what you proposed aims at achieving exactly the same thing as mine but IMO it's overcomplicated... don't get me wrong if you like electronics and building it would be fun for you - do it... but if you expect us to comment on this design then I say you want to make it more difficult that it has to be

trust me there are other things that you have to worry about when you make a semi..... the more parts there are the bigger the chance that something will go wrong

Children are the future

unless we stop them now

-

btrettel

- Specialist 3

- Posts: 386

- Joined: Sun Feb 03, 2008 4:40 pm

- Been thanked: 1 time

-

Contact:

Thu Jan 01, 2009 10:25 pm

I agree with POLAND_SPUD about electronics. While they'd work (indeed, I considered them for a design a while back), it's much simpler to use air valves. An air cylinder and a QEV/sprinkler valve can both be worked with a simple directional control valve. And you can use a 3-way valve--just make the air cylinder part of the air chamber or simply the air chamber by itself. It'll be vented with the projectile.

Check out POLAND_SPUD's link and my

FANG automatic Nerf gun for some ideas.

-

Easterbunny

- Private

- Posts: 19

- Joined: Wed Jan 02, 2008 1:24 pm

Thu Jan 01, 2009 10:59 pm

very good canon poland. I’m going with the electronics because I work well with them, and something that uses the recoil to push the bolt back might not work with nerf darts

it would need 3.5 in of movement to allow the dart to pass. and I might be able to achieve full auto by having timer B in astable mode (a 'wave' of on/off) with timer A's trigger to B's out.

so to answer the question, no electronics are not needed for a semi.

-

Easterbunny

- Private

- Posts: 19

- Joined: Wed Jan 02, 2008 1:24 pm

Thu Jan 01, 2009 11:07 pm

I agree with POLAND_SPUD about electronics. While they'd work (indeed, I considered them for a design a while back), it's much simpler to use air valves. An air cylinder and a QEV/sprinkler valve can both be worked with a simple directional control valve. And you can use a 3-way valve--just make the air cylinder part of the air chamber or simply the air chamber by itself. It'll be vented with the projectile.

Check out POLAND_SPUD's link and my FANG automatic Nerf gun for some ideas.

yes i saw that but it wasn’t exactly what I was aiming for, I plan on installing this into a nerf gun with slight modification to the shell for the solenoid valve. the one I posted will go into a nerf longshot.

-

TurboSuper

- Corporal 5

- Posts: 986

- Joined: Thu Jun 16, 2005 1:44 pm

- Been thanked: 1 time

Thu Jan 01, 2009 11:09 pm

Electronics are awesome, and certianly have their advantages over a purely mechanical design...I say go for it

Besides, for someone well-versed in digital electronics, that design is far from complicated...believe me...

"If at first you dont succeed, then skydiving is not for you" - Darwin Awards

-

POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

Fri Jan 02, 2009 6:49 am

something that uses the recoil to push the bolt back might not work with nerf darts

it doesn't use recoil... this kind of designs use a 3 way valve, a QEV/piston valve and a single acting air cylinder that is hooked up to the chamber...

the valve fills the gun in one position and pilots it when you actuate it...

since the air cylinder is hooked up to the chamber it extends when the gun is pressurised and retracts when you actuate the valve

mine works more less the same - the only difference is that I used a 5 way valve just becasue I didn't have a good 3 way valve... the air cylinder is hooked up to the 5 way valve directly...

what you want to achieve with electronics is basically done by the 3 way valve itself... your design requires you to buy a 3 way or 5 way valve anyway... that's why I believe that electronic ciructs are 'redundunt' here... so it's not that I consider elecronics as something evil

Last edited by

POLAND_SPUD on Fri Jan 02, 2009 1:05 pm, edited 1 time in total.

Children are the future

unless we stop them now

-

Hotwired

- First Sergeant 3

- Posts: 2599

- Joined: Fri Oct 13, 2006 5:51 am

- Location: UK

Fri Jan 02, 2009 11:25 am

Easterbunnys design requires a 5 port valve because he's drawn in a double acting cylinder. If it was a spring loaded cylinder then a 3 port valve could be used instead.

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Fri Jan 02, 2009 11:41 am

One problem you might run into is the fact that sprinkler valves tend to take a while to seal up again.

I would use a mechanical reloading device such as a blow-forward breech, or as suggested above connect the reloading piston directly to the chamber, then use a direct acting solenoid valve as a pilot for a piston valve or a QEV.