Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

Mitchza89

- Sergeant

- Posts: 1056

- Joined: Tue Jan 09, 2007 12:05 am

Sun Jul 26, 2009 9:44 pm

It's been a while since I've built something so I thought I'd make a new pump that should take me past the 500psi mark. I wanted to create a simple check valve that I knew would work. I used to have blowouts at about 300ish psi with my old pump due to the check valve I made with washers, o rings and bolts.

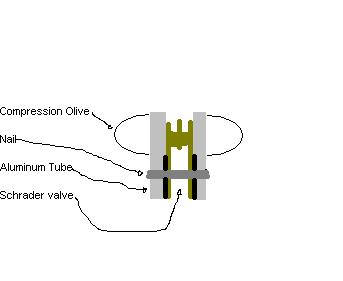

As all of the old spudders know, I use compression fittings for just about everything so I thought I'd put that to use in the new check valve. I got a schrader valve and sleeved it in 12mm aluminum tubing. I just trimmed the rubber off the back and squeezed it in so it was an air tight fit. I drilled a nail through the back of the aluminum tubing and through the brass tubing inside the valve to prevent a blow out.

It was by far the quickest build I've done for a check valve. Because of it's simplicity I shouldn't have any problems (Don't jinx myself!

)

Nothing much can be said about the pump head. I wanted to do the piston head out of aluminum rod but I had none around so hard wood did the trick

Thanks guys!

-

Attachments

-

-

-

-

- The nail grinded to fit flush.

-

- Crappy quality but you can just see the nail through the back of it.

-

-

-

- Pretty self explanatory.

- untitled.JPG (8.4 KiB) Viewed 7700 times

Last edited by

Mitchza89 on Sun Jul 26, 2009 11:27 pm, edited 1 time in total.

-

spudtyrrant

- Corporal

- Posts: 550

- Joined: Fri Jan 02, 2009 6:10 pm

Sun Jul 26, 2009 10:26 pm

nice job first of all.

but i have used my copper 3/4 inch pump that i built last week to 450psi and haven't had a blowout yet it is the pump from gippetos tutorial.

also i'm wondering how your nail set-up prevents blowouts could you show me a diagram please.

btw what time is it there it's 12 o' clock where i live

edit: omg i'm stupid maybe i should pay attention to the drawings

Last edited by

spudtyrrant on Mon Jul 27, 2009 8:48 pm, edited 1 time in total.

-

Mitchza89

- Sergeant

- Posts: 1056

- Joined: Tue Jan 09, 2007 12:05 am

Sun Jul 26, 2009 11:29 pm

Thanks very much for the nice words

.

I've added a diagram of the valve to the top of the page above the other pictures. Hope it helps!

Spudtyrant, The compression fitting keeps the aluminum tubing (outside of the valve) firmly in place but I was worried about the schrader valve blowing through the the tube. The nail is to prevent that from happening.

Cheers

-

jmadden91

- Specialist 2

- Posts: 246

- Joined: Thu May 07, 2009 6:03 pm

- Location: Queensland, Australia

Sun Jul 26, 2009 11:59 pm

Hey mate, man thats sweet. Where do you get your aluminum tube?

-

Mitchza89

- Sergeant

- Posts: 1056

- Joined: Tue Jan 09, 2007 12:05 am

Mon Jul 27, 2009 12:06 am

Thanks a lot mate. I got it from Bunnings. It's 8mm, it's 5 or 6 bucks a meter I think.

How's your pump and boom stick coming along?

-

jmadden91

- Specialist 2

- Posts: 246

- Joined: Thu May 07, 2009 6:03 pm

- Location: Queensland, Australia

Mon Jul 27, 2009 12:10 am

Haha have to wait until pay day on wednesday then see how much I have left after paying my mechanic before I can hit bunnings to start it.

Im going to get myself a fridgy for a pump I think. Wow thats sick I have only ever seen copper there before. Is it in the plumbing section?

Btw your piston is a stunner mate congrats

-

Gippeto

- First Sergeant 3

- Posts: 2504

- Joined: Sat Jan 19, 2008 10:14 am

- Location: Soon to be socialist shit hole.

- Has thanked: 2 times

- Been thanked: 17 times

Mon Jul 27, 2009 1:05 am

Hey Mitch.

Nice job, ... as usual. 8)

"It could be that the purpose of your life is to serve as a warning to others" – unknown

Liberalism is a mental disorder, reality is it's cure.

-

Mitchza89

- Sergeant

- Posts: 1056

- Joined: Tue Jan 09, 2007 12:05 am

Mon Jul 27, 2009 1:16 am

Haha money is always a problem aye mate, every spudders problem.

Thanks alot for the nice comments guys!

-

Mr.Sandman

- Corporal 3

- Posts: 762

- Joined: Fri Mar 28, 2008 9:10 am

-

Contact:

Mon Jul 27, 2009 7:40 pm

I like the check valve design. Could i borrow the idea for my old pump? I have to make a new one seeing as though the pump shaft is sticking in my ceiling!

Yeah, it's that important.

-

Mitchza89

- Sergeant

- Posts: 1056

- Joined: Tue Jan 09, 2007 12:05 am

Mon Jul 27, 2009 10:14 pm

Oh no! I had a check valve I made blow out at 300psi. It took me off guard so I was knocked on my rear end.

Your more then welcome to Sandman! Have fun with it mate

-

spudtyrrant

- Corporal

- Posts: 550

- Joined: Fri Jan 02, 2009 6:10 pm

Mon Jul 27, 2009 10:51 pm

lol that SUX just make the check from gippeto's tutorial i have taken it to 450psi and let it sit over night more than once with no failure in the check or any leaks

-

Brian the brain

- Moderator

- Posts: 3497

- Joined: Mon Dec 05, 2005 2:06 am

- Location: Holland

- Been thanked: 7 times

Tue Jul 28, 2009 2:55 pm

Maybe you guys remember the front teeth-broken upper jaw incident I had with a similar pump...

Still carry the mark of the nut in my cheek..\

That checkvalve used similar material to the olive to keep the checkvalve in position...It blew..

In my opinion the aluminium section could be blow right trough the fitting if the olive looses it's grip.

Well...I know compression fittings can hold quite a lot of pressure...just...make sure the entire aluminium section has NO way of blowing out.

I love the retro wooden piston!!

Gun Freak wrote:

Oh my friggin god stop being so awesome, that thing is pure kick ass. Most innovative and creative pneumatic that the files have ever come by!

Can't ask for a better compliment!!