So far i've tested the gun at about 40 psi. I've only checked the pressure using a tire gauge, bu i'm thinking of adding a pressure gauge to the launcher.

Let me describe the gun

the chamber is approx 14" long 2" sch40 pvc

the barrel(inside the chamber) is about 11" long 1" sch40 pvc

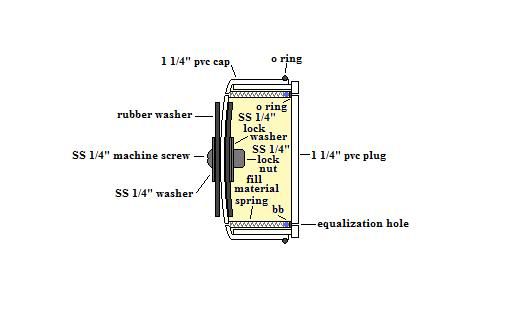

the piston is an 1 1/4" sch40 pvc cap with a piece of rubber that fits inside the 2" pvc with just enough room to slide freely.

the piston is assembled 1/4" machine SS(stainless steel) machine screw, SS washer, rubber washer, PVC cap, rubber washer(fits snug inside the cap), SS washer, SS lock washer, SS lock nut.

At the back of the chamber is a 2" rubber tip toe washer (i think thats what it was called) for a bumper

The pilot valve is a 1/4" NPT 140 psi pop-off/safety relief valve, attached center on the butt cap of the chamber

the fill valve is an 1/8" NPT schrader valve

I believe the piston has about 1/2"-3/4" to slide inside the chamber.

The piston can be heard sliding freely when the launcher is shaken vertically.

I've tried spraying silicon oil into the chamber by removing the schrader valve and spraying around the piston, then shaking the launcher to slide the piston and spread the oil.

I haven't had any issues with the schrader valve releasing the piston, but neither will the pilot valve when the chamber is pressurized.

If i can get the piston to work, and the schrader valve does release the piston when finished filling, i plan on adding an 1/8" ball valve in an alternative fill assembly.