Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Mon Aug 13, 2007 4:35 am

I think once you remove the sear, the piston will move back and stay there - the difference between the middle disk and smaller disk is going to have to be minimal to allow the spring to reset the whole unit.

And Jack, Ever think of making a whole gun out of moulded epoxy? Valve, fittings and all?

well, I did

cast my own breech recently for the cartridge project, it would be possible to make an all-epoxy launcher (except maybe the breech seal and a schrader) though apart from the limited coolness factor it wouldn't be worth the expense or the effort.

@Jack: interesting design there. I'd thought of something like that, but what exactly is the advantage over the traditional barrel-sealer? B/c it looks like that would be extra work for not much benefit that I can see.

The advantage would be a faster opening time - because instead of accelerating slowly, the sealing part of the piston would be yanked suddenly due to the increased momentum - though to what extent it would be faster and how much better the performance will be, I cannot say (and in practical terms, I would it will be that significant)

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

Marco321

- Corporal

- Posts: 540

- Joined: Tue May 15, 2007 2:56 am

- Location: Sydney, Australia

Mon Aug 13, 2007 4:43 am

I see, is there a way to accurately determine the exactly how big each disk must be?

Failure to plan is planning to fail.

The 7 P's - Proper Prior Preparation Prevents Piss Poor Performance

-

jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Mon Aug 13, 2007 4:52 am

You can determine the amount of force that it's being exterted by the piston against the spring by multiplying the difference in areas between the larger and small spring by the pressure.

You can then compare this value to the strength of your spring, which you can determine by progressively applying weight to it and determining by how much it will compress, so you'll know what sort of tension you'll need to counter it.

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

Marco321

- Corporal

- Posts: 540

- Joined: Tue May 15, 2007 2:56 am

- Location: Sydney, Australia

Mon Aug 13, 2007 5:22 am

Oh ok cool. Thanks for that.

Failure to plan is planning to fail.

The 7 P's - Proper Prior Preparation Prevents Piss Poor Performance

-

dongfang

- Specialist 4

- Posts: 448

- Joined: Sun Aug 27, 2006 8:02 am

- Location: Switzerland

Mon Aug 13, 2007 6:43 am

Hi,

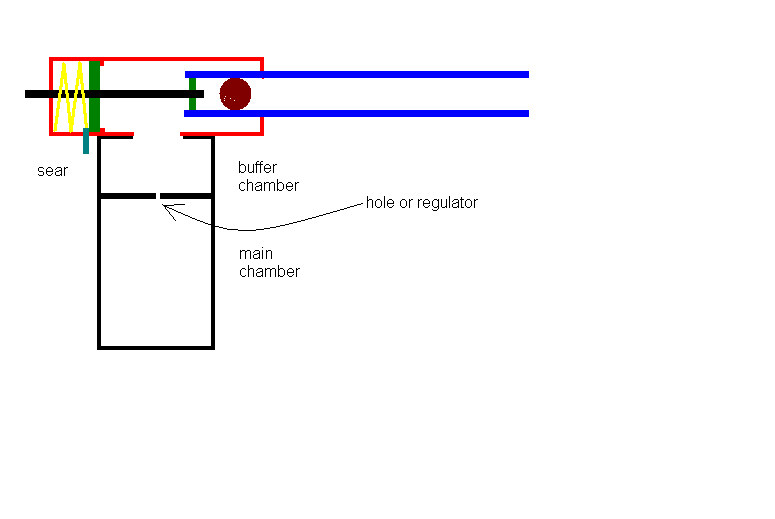

Wouldn't this be simpler and more efficient?

Principle of operation: When loaded, the force backwards on the large piston (which should really only be slightly larger than the barrel plug) exceeds the force forwards on the barrel plug. Withdrawing the sear (oops, move that a little backwards, so the piston will not expose the hole is comes through!) will make the bolt jump backwards, firing the gun. When the buffer chamber is about empty, the spring re-seals the valve and the buffer chamber refills.

Mechanical linkage could be added to: Control a valve between the two chambers, and to push/pull an auto loader. Not on drawing.

EDIT: Aaaah, I missed the point that the original design had a secondary chamber built into it - between the two front pistons. Good idea; maybe better than mine too.

EDIT again: But there's still one part of my design that could be useful here: Sealing the barrel by pushing a plug into it, instead of sealing flat against its end. That way, the valve could be made to open faster (because the bolt has picked up some speed when it unseals). It could be designed to take place right after the inter-chamber piston has separated the chambers.

Regards

Soren

-

Attachments

-

- DDSAV-1 - Dongfang's Darn Simple Automatic Valve

- automatic_valve.PNG (11.02 KiB) Viewed 2168 times

-

spud yeti

- Sergeant

- Posts: 1030

- Joined: Tue May 08, 2007 1:41 pm

- Location: Cape town south africa

-

Contact:

Mon Aug 13, 2007 9:09 am

EDIT again: But there's still one part of my design that could be useful here: Sealing the barrel by pushing a plug into it, instead of sealing flat against its end. That way, the valve could be made to open faster (because the bolt has picked up some speed when it unseals). It could be designed to take place right after the inter-chamber piston has separated the chambers.

It depends on how smoothly the piston runs in the barrel, because if it is airtight, it may be quite "hard" to pull out, thus decreasing speed, whereas a piston flat against the barrel doesnt have this restriction. I guess its all about how well crafted it is though.

really good quote/phrase here

-

Skywalker

- Specialist

- Posts: 194

- Joined: Sun Aug 05, 2007 7:22 pm

- Has thanked: 9 times

- Been thanked: 9 times

Mon Aug 13, 2007 9:31 am

Wow, what a profusion of automatic piston gun designs! This is getting crazy.

I'm with Jack on Marco's most recent design: I think that it might just get hung up halfway open and vent the whole tank. As for Dongfang's idea, I suppose it would work, but that small fill port into the buffer chamber is going to be the catch. If you size it too big, the valve will never reseat. If you size it too small, you ROF will be pathetic.

Come to think of it, this principle is very similar to my

second automatic diaphragm idea. But I like dongfang's better because the sear-trigger gives better fire control than does valving the air input.

-

Modderxtrordanare

- Corporal 2

- Posts: 686

- Joined: Mon Nov 20, 2006 1:22 pm

- Location: Texas

Mon Aug 13, 2007 12:06 pm

Skywalker wrote:I'm with Jack on Marco's most recent design: I think that it might just get hung up halfway open and vent the whole tank. As for Dongfang's idea, I suppose it would work, but that small fill port into the buffer chamber is going to be the catch. If you size it too big, the valve will never reseat. If you size it too small, you ROF will be pathetic.

Then tap and thread in a regulator in there, and make the main chamber thread on and off so you can fine tune the regulator so the valve still re-seats and you still can get a decent ROF.

-

dongfang

- Specialist 4

- Posts: 448

- Joined: Sun Aug 27, 2006 8:02 am

- Location: Switzerland

Mon Aug 13, 2007 6:39 pm

Hi,

With "the original design" I mentioned in my first EDIT in my last posting, I really meant Marco´s revised design.

I agree that it has a problem resealing: There will always be the main chamber pressure on the right hand side of the large piston. So either the spring will have to overcome that (and the gun won´t fire when triggering it) or the main chamber pressure will become very low after the first firing, and the valve will really reseal.

If implementing my design in a wye (I know rated wyes are hard to get in America, but here they are not - haaa ha ha), imagine the side branch of the wye pointing down to the right on my drawing. I think it could be fesible then to put a small ball valve between the two chambers, and have a connecting steel rod couple the handle on the ball valve to the bolt of the DDSAV. The ball valve opens when the bolt is in the forward position, and closes otherwise.

Or one could introduce another piston, to cover the inlet hole (like the exhaust on a silly 2 stroke engine w/o exhaust valves). Or even couple it to a nice regulator in some way.

Oh, and as for that with the friction in a barrel plug seal:

Assume a GB size barrel. That has a cross section of about 15 cm^2. Say the pressure is 6 bar, and that the large piston has 20% more area than the barrel cross section. That´s about 180 Newtons of force on the bolt, in the direction of the sear and the spring. Even if the spring takes, say, 50 N of that, I would say there is still plenty to tear out the plug.

Maybe the coolest thing to do would be to combine the two solutions: Make a plug that sticks into the barrel and has a rather loose and maybe not perfect o-ring seal. Add a flange at the end of the plug that seals against the end of the barrel.

EDIT:

Thinking of it once more: Having a sear holding a disk against the end of a barrel is going to be really hard to get to work. The disk is going to need a gooooooood hard push to seal properly, and as the buffer chamber is pressurized, any flexing and slack in the sear mechanism is going to let the large piston pull the disk away from the barrel. Just a little, but enough that I would worry about it...

Regards

Soren