Page 1 of 1

A little help with my copper piston valve??

Posted: Mon Mar 31, 2008 2:10 pm

by MB1380

Hey guys, ive been reading up here with a few months and decided to build a copper piston gun, i used a 3/4 3/4 1/2 tee for the piston holder and in using a blow gun for the trigger, also a 3/4 pipe for the cylinder.

Im a little short on fittings so what ive done is put a shrader valve on to a 3/4 blank for the fill/trigger and piped this onto the blow gun which has another shrader valve at the other end. Both of the valves on these shraders have been removed.

For the piston ive used a wooden dowel which fits perfectly in the 3/4 pipe, it has some rubber from a bike tube screwed on with a washer.

Originally i did not have the straight placed behind the tee but i felt it was needed to try get a better suction on the piston when firing the blow gun.

My problem is, it fills with air fine but when i use the blow gun it just leaks out all of th air and does not move the piston (which moves quite freely when not under pressure)

When its under pressure i tried physically pushing it from the barrel side and noticed it takes a lot of force to release the air.

Can anybody shed some light on where in going wrong??

Thanks in advance

Posted: Mon Mar 31, 2008 2:24 pm

by Hubb

Your piston face needs to be larger than the barrel.

This link should clear things up a bit. Notice how the size of the piston in relation to the barrel is? That's what needs to happen in yours. Oh, and it probably wouldn't hurt to cut your pilot volume a bit.

Posted: Mon Mar 31, 2008 2:30 pm

by MB1380

hubb017 wrote:Your piston face needs to be larger than the barrel.

This link should clear things up a bit. Notice how the size of the piston in relation to the barrel is? That's what needs to happen in yours. Oh, and it probably wouldn't hurt to cut your pilot volume a bit.

My piston is bigger alrite tho, its a 3/4 dowel and it seals up against the 1/2 section of the tee, the part sticking into the barrel is just the washer. i think thats what you ment ya?? im not sure i could be picking you up wrong...

Posted: Mon Mar 31, 2008 2:50 pm

by Pyro Ninja

MB1380 wrote:it seals up against the 1/2 section of the tee

If thats the case, then you may not have enough air infront of the piston to push it back, you could put a 1/4" nipple in backward at the barrel side of the Tee.

I would also suggest upping the 1/2" Tee to a 3/4" one (gives a little more room to work with).

Also you may find that pistons with bolted on and or glued on sealing face don't always seal well and they often can get ripped off.

I have found that a machined down rubber cork seals/works perfectly in smaller caliber guns (it also acts as its own bumper)

Well thats my 5cents

Posted: Mon Mar 31, 2008 3:16 pm

by DYI

So what air is pushing on the front of the piston if it seals on the front face of the tee.

Just to tell you, you can't "suck" anything back with gases - you can only push things with them.

Posted: Mon Mar 31, 2008 3:18 pm

by Hubb

Pyro Ninja wrote:If thats the case, then you may not have enough air in front of the piston to push it back,

That's what I was trying to say. Sorry about that.

Up the tee and the piston and see what that does.

Posted: Mon Mar 31, 2008 3:27 pm

by MB1380

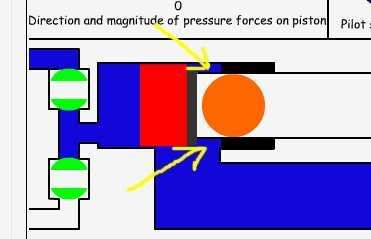

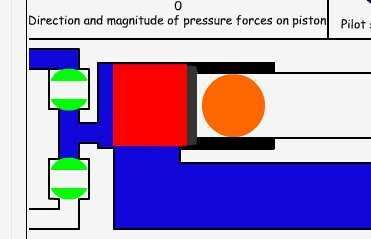

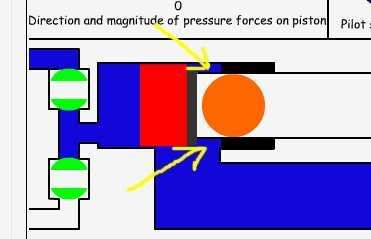

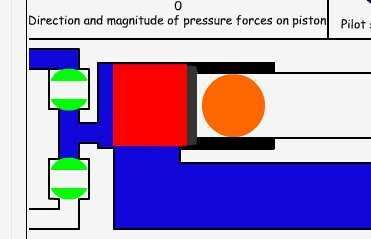

Oh rite, i see where im going wrong now, this is what i need...

And this is what ive got....

So i need to run the barrel further into the tee, only problem now is the lip on my fitting that stops the pipe entering the tee.

I suppose if i grind this down and get the pipe into the tee,i should be sorted?? Cheers lads

Posted: Mon Mar 31, 2008 3:29 pm

by Hubb

Copper and brass are pretty easy to file out (brass is a little harder). I just filed a brass fitting last night with little effort. Be patient and it'll work. How hard would it be for you to get a bigger tee? That would probably be the best bet.

Posted: Mon Mar 31, 2008 3:35 pm

by MB1380

hubb017 wrote:Copper and brass are pretty easy to file out (brass is a little harder). I just filed a brass fitting last night with little effort. Be patient and it'll work. How hard would it be for you to get a bigger tee? That would probably be the best bet.

I could get another tee no problem but i want to keep my barrel as small as possible....

Are you saying a tee with 3/4 on all sides? not sure how i could get the barrel to match into that if ya know what i mean??

Posted: Mon Mar 31, 2008 4:31 pm

by MB1380

Ok i just went out and modified it but still no good?? i ran the 1/2 inch into the middle of the tee, cut down the piston size and still no good. it holds pressure fine but just leaks the whole lot out of the blow gun when fired, i can hear it open just at the very end of the blow guns exhausting.

The piston is not 100% sealed around the pilot area as its just wood on brass but i dident think this was necessary,

Any other pointers lads??

Posted: Mon Mar 31, 2008 4:34 pm

by Hubb

Get a 1" x 1" x 1" tee and put a reducer bushing in it (1" x 1/2" to keep the same barrel). File out the bushing so that the 1/2" barrel slides through it. Fix it to the center of the new tee (like you have it now).Then, make a new piston that is bigger than the one you have.

There is still just not enough space between the tee walls and that barrel.

Posted: Tue Apr 01, 2008 12:15 am

by Gippeto

More air is leaking past your piston than your pilot can flow.

Minimize leakage past the piston (a wrap of tape)

Minimize pilot volume.

Maximize pilot flow. (remove restrictions)