Figured I would start with this pic just so everyone knows I learned my lesson

The Main Parts

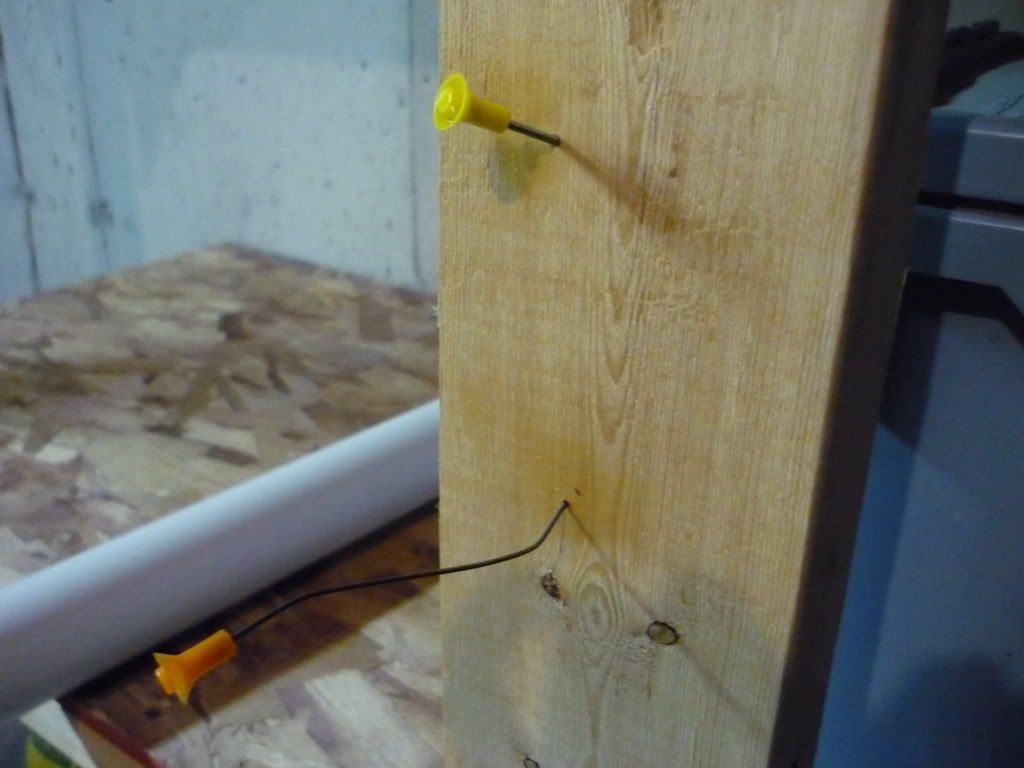

Barrel support and endcap assembled

The whole system laid out as in final assembly next to PVC

I eventually replaced the air gun with a ball valve

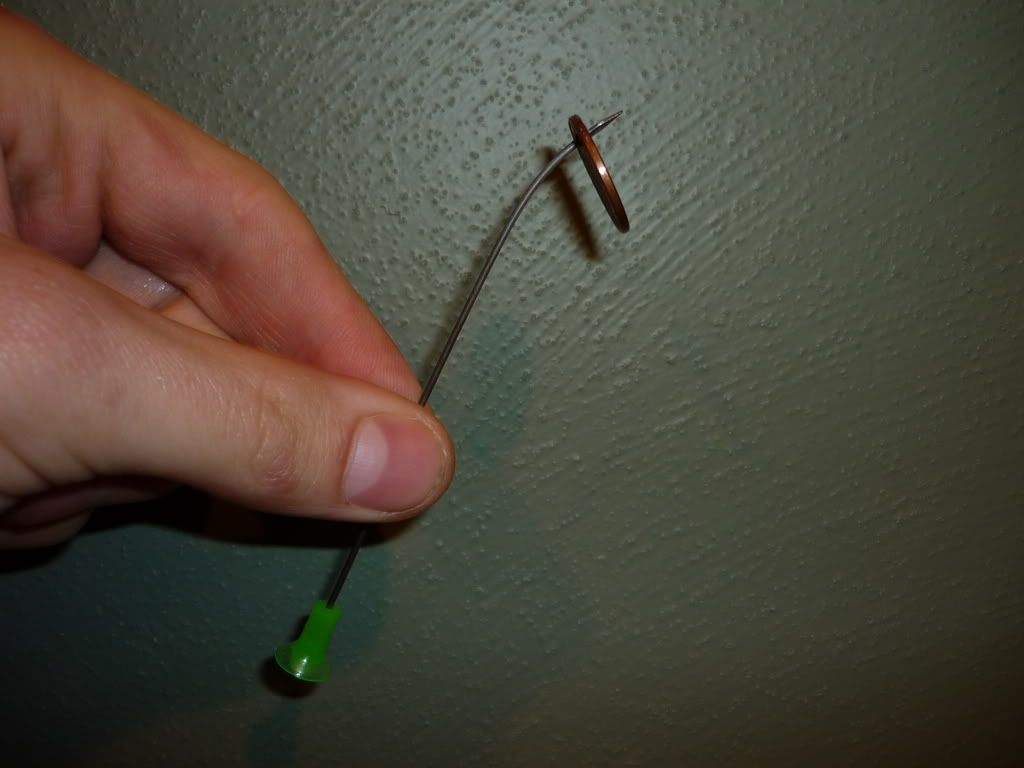

The piston with my first attempt at finding some bubber laying around my house

This didnt seal well enough so I had to disassemble it and try again but I eventually found a neoprene patch for fishing waders (spelling?) which once I removed one of the fabric outer layers worked perfectly.

Final assembly

And just so none of you have to ask. Yes that is hotglue sealing the endcaps. Thats why I added the screws to ensure they will not come flying out. This is just a low pressure gun I made quickly so that I could fiddle with a piston and the great thing about hotglue is that it dries in seconds and once you get it hot again melts so that you can fix the mistake you made earlier

I have now added 8 screws to each cap just to be extra careful and so far no detectable leaks until I hit 80 psi. Not bad for hot glue

And here is my result

At only 30 psi

Looks like a need to find a new ammo source

The only problem I have encountered so far is that it fires perfectly at 30-40 psi but at 80 psi alot of air comes out the ball valve before the piston pops. Its still more powerful but it seems like way too much air is flowing out the ball. Any ideas?