http://www.spudfiles.com/forums/cannon- ... 19145.html

Although the delayed blow-back seems to be the central feature of this airgun, it was just an easier and more efficient option compared to direct blowback.

I decided on using blowback, instead of blow forward, as I liked the idea that the new projectile is loaded after the shot not during.

Also air flow, using this setup, isn't as restricted.

I had originally planed on using a chamber connected air ram to operate the bolt, but the cocking action on a blowback system just seemed really satisfying

The delayed aspect was appealing as it uses pressure left over after the projectile is up to speed, and has positive effects on noise reduction and muzzle blast.

(Then again, a new problem showed up as far as sound levels were concerned. Overall sound levels were reduced to the extent that at short range projectile impact is much louder than the shot, but firing from the shoulder became uncomfortable. A problem often attributed to bullpup designs. Some will probably say, "shoot a real gun you'll fin out what loud is", but as far as I'm concerned if it makes your ears ring then its not good.)

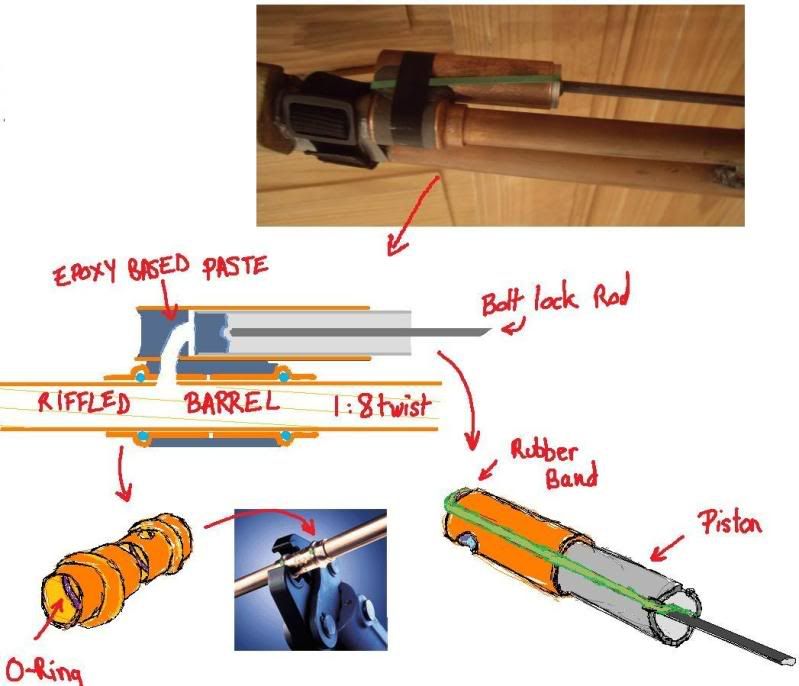

So first of all, here is a cross section of the gas piston.

It a pretty basic component. I will operate even when dry firing, but the bolt then doesn't move back all the way.

The piston is made from 20mm aluminium tube and epoxy based paste.

The outer tube is 22mm copper. The air seal is achieved thanks to silicone lubricant and a large enough surface area.

The gas piston was built in such a way to be able to remove it or move it up or down the barrel. The closer to the muzzle the better, but if the bolt remains locked for too long it might not receive enough pressure to recoil

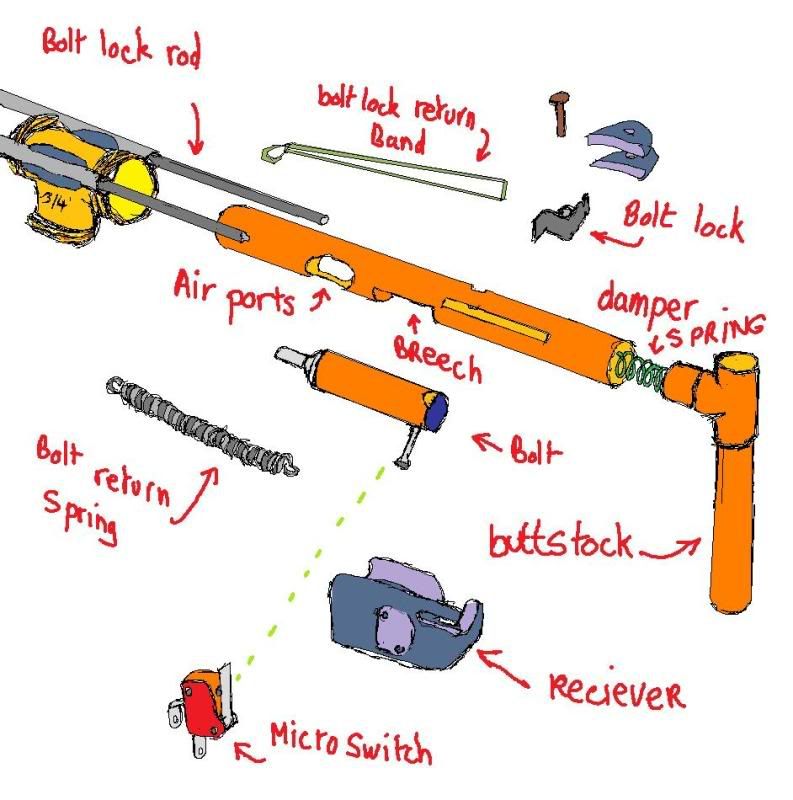

The gas piston was built in such a way to be able to remove it or move it up or down the barrel. The closer to the muzzle the better, but if the bolt remains locked for too long it might not receive enough pressure to recoilHere is an exploded view of the loading assembly:

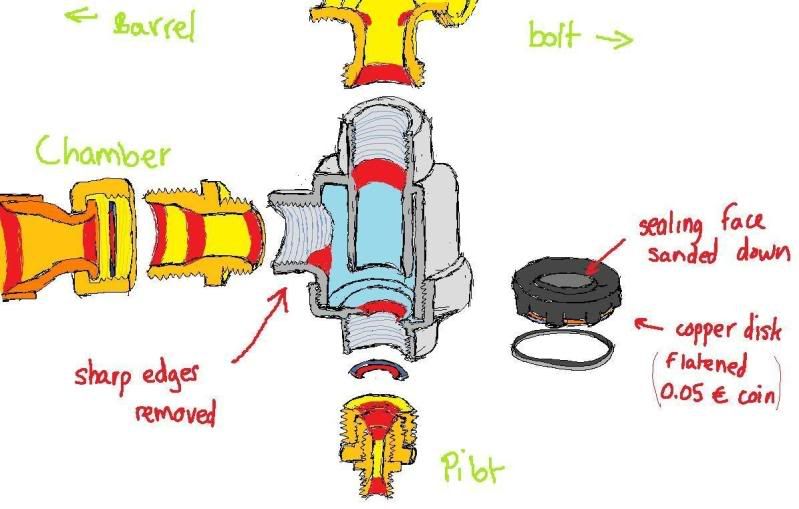

Parts of the QEV and fittings that were modified for more efficient flow (in red):

Even though it was presented in the inovative design contest, this air rifle was originaly meant to be used for attemping some long range (in the world of big bore air rifles) target shots. (The idea was to produce some sort of scaled down gepard M6, firing the yet to come 14.5 Whisper round

The original specs I wanted to achieve were along the lines of:

-muzzle velocity of at least 230m/s

-effective range of 200+m on a large target (not expecting extreme accuracy at that range)

-at least the possiblity of semi-automatic fire

-air efficient but using a QEV, so minimal pilot volume, good flow through valve, minimal losses through loading mechanism, maximum barrel length etc...

-A reasonable amount of shots without having to refill (enough to hopefully make a few succesful long range shots)

-portable and practical

-try for good consistency and accuracy

-give the possiblity of experimenting with the diesel effect

-be classed as a bigbore airgun

I then added:

-Automatic fire ability

-Select fire abilty (easy to do, without tools)

-A cool way of manualy cycling the action

And then decided the automatic fire should not be any less powerful than semi-automatic or single shot.

I had at first designed a fully pneumatic firing system, but the select fire wasn't as straight forward as a 3 position switch and automatic fire would have relied on a pop off set up, making full auto shots less powerfull.

Fully pneumatic select fire (using only one trigger) can be achieved using a manual 5/2 valve and two small ballvalves. The only action needed would be to use the ballvalves. Although one of them would have to be ajusted with care (a mark could be used) to an intermediate position as it controls the rate of fire the pop off valve generates.

The electronic 3 way valve set up, is more efficient during automatic fire, and prevents firing in the event of a jam during loading of a projectile(it saves suffering an explosion of high pressure air to the face).

Also it is much more compact and using a microswitch as a trigger is very convienient.

Some RLD (not quite Very Low Drag, bur Reasonably Low Drag

As you will have noticed, the build I made of the #3 contest entry was disapointing. I only started it once I realised it was going to be too late, and that happened to be while, amongst other time consuming activities, preparing to move to another country. I won't have the opportunity to work on any spudgun related projects in a while, so decided to post it anyway, as there was no avantage in keeping it for later.

I do have one video of the pump action, unlocking and moving the bolt back (which turned out to be out of focus), but just didn't have time to film any later features. I'll try and upload it.