First piston gun -- 1.25" PVC Coax

Posted: Wed Jul 11, 2012 6:59 pm

Hello spudfiles!  First, some background: Someone turned on the spudding switch on me lately... and so I was itching to get back in the groove. The last piston cannon I built (3 years ago, freshman year) failed because of flow issues... It was a 2 inch tee barrel sealing cannon. I'll work on that when I have the time. I've also built a pen gun (which, of late, got something jammed down the barrel... oops. I'll fix that too) But in the meanwhile, I built a whole new cannon with all the experience gained from browsing the forums in the past years (and a new drill press and scroll saw, too).

First, some background: Someone turned on the spudding switch on me lately... and so I was itching to get back in the groove. The last piston cannon I built (3 years ago, freshman year) failed because of flow issues... It was a 2 inch tee barrel sealing cannon. I'll work on that when I have the time. I've also built a pen gun (which, of late, got something jammed down the barrel... oops. I'll fix that too) But in the meanwhile, I built a whole new cannon with all the experience gained from browsing the forums in the past years (and a new drill press and scroll saw, too).

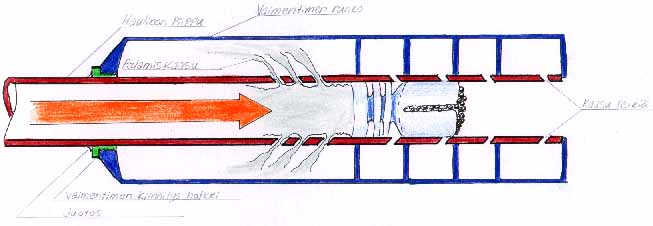

It's pretty simple...

Here's the suppressor:

I found a 1/2" "cut-off rise" consisting of many threaded segments together... With a mallet it was a perfect fit inside of 3/4" PVC. 1/4" holes are drilled in a spiral all around the inner. The bushings to bring it up to the 1.5" PVC sheath are cut out of plywood on my scroll saw, and there's a screw countersunk into the sheath to hold things together. And there's a 1/2" female coupler on the front of the barrel on the cannon.

And this:

is how I kept a blowgun pilot assembly to around $5. (without the blowgun I already had). The schrader valve is off a bike inner tube, cut to fit a 1/2" end cap perfectly, and JB welded into the cap. Why make the whole thing brass if you don't have to? haha. The tee is threaded on the bottom leg, where a 1/2" to 1/4" threaded adapter connects to a 1/4" galvanized closed nipple and then to the blowgun.

It doesn't work yet. lol. Can't wait to replace the seals

Specs:

cost about $20 USD (haha, no brass!!!)

Chamber: 1.25" sch 40 PVC, ~35" long

Barrel: 1/2" sch 40 PVC, ~37" long

Piston: 3/4" PVC end cap with rubber washer bolted to the front

Pilot: will be a blowgun once I replace the seals on it (modded it already... can someone tell me if this is enough, though?). For now I'm using a 1/2" PVC ball valve.

I've only been able to test it up to 80 PSI or so, because I don't know how to increase the limit on my puny 2 gal compressor's auto shut-off.

Here are some "proof of function" (don't deserve to be called test shots) at 60 PSI, AA battery as ammo. The sound on video is so wimpy, ugh.

Here's the suppressor:

I found a 1/2" "cut-off rise" consisting of many threaded segments together... With a mallet it was a perfect fit inside of 3/4" PVC. 1/4" holes are drilled in a spiral all around the inner. The bushings to bring it up to the 1.5" PVC sheath are cut out of plywood on my scroll saw, and there's a screw countersunk into the sheath to hold things together. And there's a 1/2" female coupler on the front of the barrel on the cannon. I feel like a hit man screwing it on, hahaha.

And this:

is how I kept a blowgun pilot assembly to around $5. (without the blowgun I already had). The schrader valve is off a bike inner tube, cut to fit a 1/2" end cap perfectly, and JB welded into the cap. Why make the whole thing brass if you don't have to? haha. The tee is threaded on the bottom leg, where a 1/2" to 1/4" threaded adapter connects to a 1/4" galvanized closed nipple and then to the blowgun.

It doesn't work yet. lol. Can't wait to replace the seals

Specs:

cost about $20 USD (haha, no brass!!!)

Chamber: 1.25" sch 40 PVC, ~35" long

Barrel: 1/2" sch 40 PVC, ~37" long

Piston: 3/4" PVC end cap with rubber washer bolted to the front

Pilot: will be a blowgun once I replace the seals on it (modded it already... can someone tell me if this is enough, though?). For now I'm using a 1/2" PVC ball valve.

I've only been able to test it up to 80 PSI or so, because I don't know how to increase the limit on my puny 2 gal compressor's auto shut-off.

Here are some "proof of function" (don't deserve to be called test shots) at 60 PSI, AA battery as ammo. The sound on video is so wimpy, ugh.

[youtube][/youtube]

It is waiting for a paint job... I was thinking black with yellow stripes, maybe even faux carbon fiber with yellow stripes.

It's pretty simple...

Here's the suppressor:

I found a 1/2" "cut-off rise" consisting of many threaded segments together... With a mallet it was a perfect fit inside of 3/4" PVC. 1/4" holes are drilled in a spiral all around the inner. The bushings to bring it up to the 1.5" PVC sheath are cut out of plywood on my scroll saw, and there's a screw countersunk into the sheath to hold things together. And there's a 1/2" female coupler on the front of the barrel on the cannon.

And this:

is how I kept a blowgun pilot assembly to around $5. (without the blowgun I already had). The schrader valve is off a bike inner tube, cut to fit a 1/2" end cap perfectly, and JB welded into the cap. Why make the whole thing brass if you don't have to? haha. The tee is threaded on the bottom leg, where a 1/2" to 1/4" threaded adapter connects to a 1/4" galvanized closed nipple and then to the blowgun.

It doesn't work yet. lol. Can't wait to replace the seals

Specs:

cost about $20 USD (haha, no brass!!!)

Chamber: 1.25" sch 40 PVC, ~35" long

Barrel: 1/2" sch 40 PVC, ~37" long

Piston: 3/4" PVC end cap with rubber washer bolted to the front

Pilot: will be a blowgun once I replace the seals on it (modded it already... can someone tell me if this is enough, though?). For now I'm using a 1/2" PVC ball valve.

I've only been able to test it up to 80 PSI or so, because I don't know how to increase the limit on my puny 2 gal compressor's auto shut-off.

Here are some "proof of function" (don't deserve to be called test shots) at 60 PSI, AA battery as ammo. The sound on video is so wimpy, ugh.

Here's the suppressor:

I found a 1/2" "cut-off rise" consisting of many threaded segments together... With a mallet it was a perfect fit inside of 3/4" PVC. 1/4" holes are drilled in a spiral all around the inner. The bushings to bring it up to the 1.5" PVC sheath are cut out of plywood on my scroll saw, and there's a screw countersunk into the sheath to hold things together. And there's a 1/2" female coupler on the front of the barrel on the cannon. I feel like a hit man screwing it on, hahaha.

And this:

is how I kept a blowgun pilot assembly to around $5. (without the blowgun I already had). The schrader valve is off a bike inner tube, cut to fit a 1/2" end cap perfectly, and JB welded into the cap. Why make the whole thing brass if you don't have to? haha. The tee is threaded on the bottom leg, where a 1/2" to 1/4" threaded adapter connects to a 1/4" galvanized closed nipple and then to the blowgun.

It doesn't work yet. lol. Can't wait to replace the seals

Specs:

cost about $20 USD (haha, no brass!!!)

Chamber: 1.25" sch 40 PVC, ~35" long

Barrel: 1/2" sch 40 PVC, ~37" long

Piston: 3/4" PVC end cap with rubber washer bolted to the front

Pilot: will be a blowgun once I replace the seals on it (modded it already... can someone tell me if this is enough, though?). For now I'm using a 1/2" PVC ball valve.

I've only been able to test it up to 80 PSI or so, because I don't know how to increase the limit on my puny 2 gal compressor's auto shut-off.

Here are some "proof of function" (don't deserve to be called test shots) at 60 PSI, AA battery as ammo. The sound on video is so wimpy, ugh.

[youtube][/youtube]

It is waiting for a paint job... I was thinking black with yellow stripes, maybe even faux carbon fiber with yellow stripes.