Page 1 of 1

Why wont my piston valve open?

Posted: Sat Feb 02, 2013 10:03 pm

by Nick481

I just made my first piston valve cannon. It is a 2" barrel sealing piston valve housed in a 2" pvc tee piloted by a modified 1 inch jar top sprinkler valve with blowgun. The piston is a 1 1/4" coupling with a plug on the front with a pretty standard sealing face. The seat is 1.5" pvc. At first i couldn't even get the sprinkler valve to seal with a pump so i hooked it up to my compressor and anything over 25 psi made the diaphragm seat up and seal. I got it to actually fire twice but it had to be above 40 psi, and then after countless other attempts even up to 80 psi the piston was not firing, the whole tank was just dumping out of the sprinkler valve. I tried covering up my equalization hole on my piston, making the pistons seal inside the housing tighter, and just about every adjustment i could. It just wouldn't work. The piston seats up to the barrel very nicely and there were no leaks in the gun. Any help is appreciated.

Nick

Posted: Sun Feb 03, 2013 12:28 am

by mark.f

In short: there's no reason it shouldn't work.

My first piston valve was a design very similar and I piloted it with a 1/4" QEV after wrapping the piston in duct tape to seal better and coating it with petroleum jelly.

With a modded sprinkler pilot, I see no reason why a reasonable fitting piston shouldn't actuate. Maybe try a different tape that seals better?

Try for a fit which requires a firm push to move the piston. Sliding freely probably means the piston is too loose.

Posted: Sun Feb 03, 2013 12:41 am

by jackssmirkingrevenge

Pretty smart setup, I like it.

First off, block your equalisation hole completely, you do not need it if your piston is not airtight.

mark.f wrote:Try for a fit which requires a firm push to move the piston. Sliding freely probably means the piston is too loose.

Agreed, it should be tight enough that you can just about move it with one finger. In this case, the ration between seat diameter and piston diameter is very small, so it needs a big pressure drop in the pilot area before it will fire. If air is leaking too much from the main chamber to the pilot, this will not allow the drop to happen and it won't fire.

In short, MOAR TAPE!

Posted: Sun Feb 03, 2013 12:54 am

by Nick481

Alright, thanks for the replies. Tomorrow ill add more tape and block off the equalization hole and see how it does.

Nick

Posted: Sun Feb 03, 2013 5:29 am

by mattyzip77

Block that eq. Hole, you dont need it. Next wrap that piston with one layer of electrical tape around piston. Now get rid of that clear hose and hook up the blowgun direct.. Lube piston too with plumbers grease or vaseline...also are you filling with a compressor??? Some pistons will not seal off of a bike pump..... good luck....

Posted: Sun Feb 03, 2013 1:08 pm

by Nick481

Alright today as you guys told me i plugged the eq hole, wrapped the back in duct tape for a hand push fit, lubed everything generously with petroleum jelly including the sealing face. Test shot on 45 psi looked to have the same velocity as my other cannon had on 110 psi, and thats 1300 foot distance worthy velocity. I am extremely impressed, thanks for all the help guys.

Nick

Posted: Sun Feb 03, 2013 9:15 pm

by mark.f

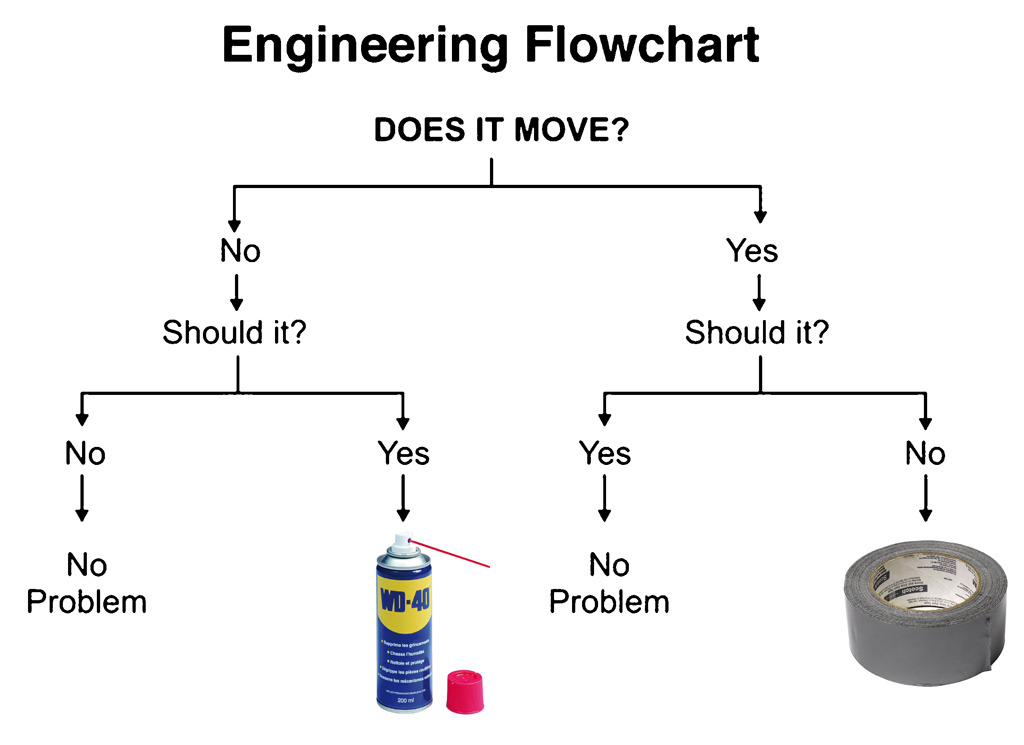

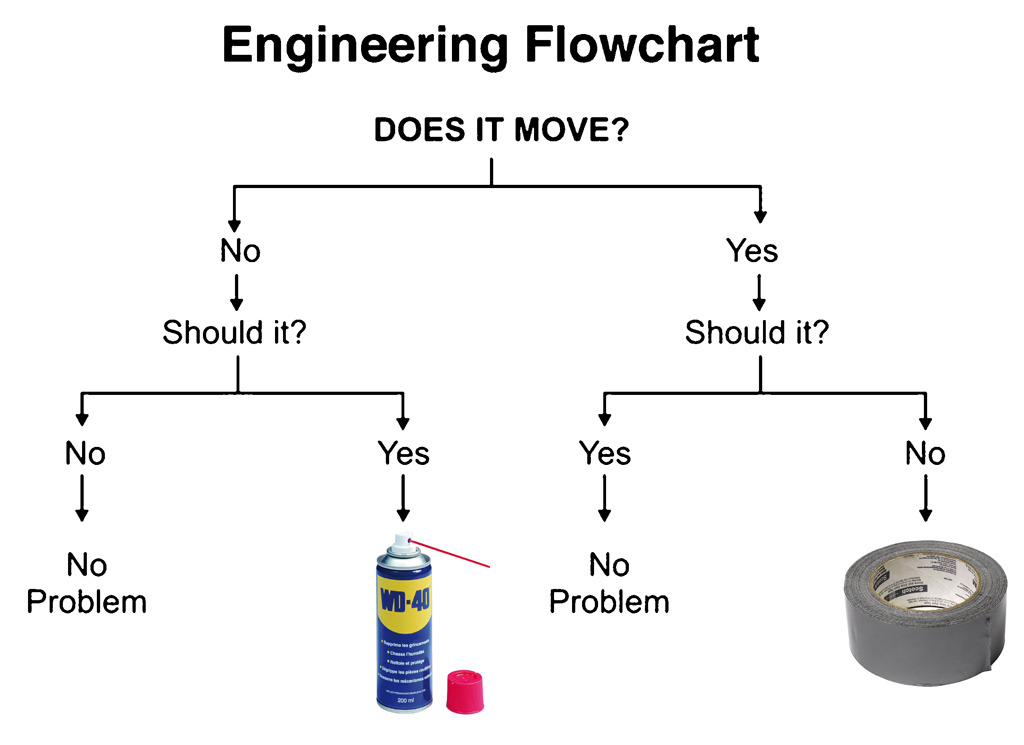

Knew it was nothing duct tape and petroleum jelly couldn't fix.

Glad it's working for you.

Posted: Mon Feb 04, 2013 12:40 am

by jackssmirkingrevenge

mark.f wrote:Knew it was nothing duct tape and petroleum jelly couldn't fix.

Well, technically it should go like this:

*ahem*

Glad you got it working, be sure to post some videos of the thing in action

Also, I would keep lube away from the sealing face, sometimes rubber tends to absorb it and do weird things.

Posted: Mon Feb 04, 2013 2:47 pm

by Nick481

It works well, but it doesn't open anywhere under 40 psi, and at that point the golf ball is going ridiculously far.. I want to be able to do lower power shots so im going to make the piston a littler better with an o ring and built in check valve. Then ill take some video on 100 psi. I might also take it out to this huge field at night with one of my night flyer golf balls and try to get some really cool Magnus and film it.

Posted: Mon Feb 04, 2013 2:53 pm

by jackssmirkingrevenge

If you have a drill press and some patience:

http://www.spudfiles.com/forums/tutoria ... 21740.html

if you make it floating o-ring, there will be no need for a check valve and it should work at any pressure.

Posted: Mon Feb 04, 2013 4:51 pm

by Nick481

If i can find the right size o ring at my local hardware store im going to do a floating o ring. I shot the cannon a few times from 70 psi up to 92 psi and it looked hilarious watching the ball fly, it mustve cleared 1000 feet within 3 seconds or maybe less but it was dancing around like a wiffle ball. I need to make a hopmup for light backspin to lengthen the flight a little. It drops too fast without it.

Posted: Tue Feb 05, 2013 1:38 pm

by mattyzip77

A 2 inch rubber sanding drum is the best piston I have ever used. Just put a washer on the front and back along with a neoprene sealing face, a bolt going through the middle andyour good to go.. you can toghten or loosen the bolt to adjust it. You can get them at harbor freight for cheap money...