Page 1 of 2

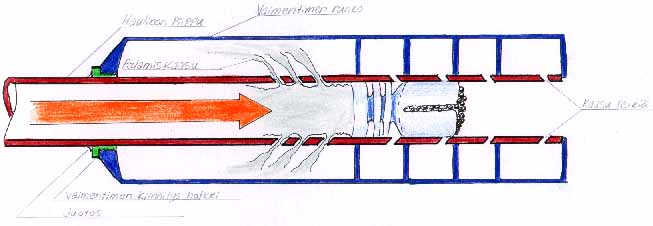

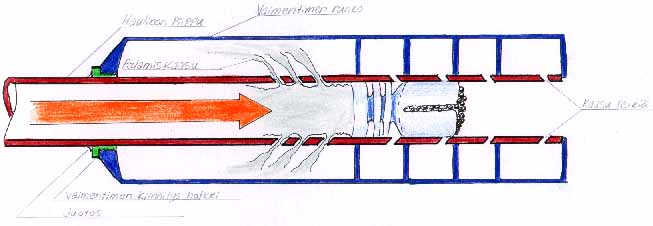

permanent sabot/piston in barrel

Posted: Tue May 28, 2013 10:50 am

by Kilash

I am in the process of testing the feasibility of a permanent sabot/ramming piston which does not exit the muzzle after firing, but instead is stopped at the end by a buffer spring or cushion. I've already build my prototype, a 2 feet long 2 inch diameter pvc barrel with a snug piston sabot made from an aluminum disc and the top of a plastic bottle. Sorry no pics yet to upload.

The idea is the full diameter piston sabot would better utilize a gun's pressure while allowing smaller diameter projectile to be used, simple dropped or pushed into holder at the front of the piston, then everything rammed down. When fired, the piston is stopped at the end of its travel, while the projectile hopefully slides free of the piston and continues downrange. It would operate similarly to a bow, where the piston acts a drawstring.

For this to be practical, the piston must 1. Be lightweight relative to the projectile so most of the energy is transfer to the projectile, and 2. Be durable enough to survive repeated firing and impact on the buffer system at the end of its acceleration.

At 70 psi, the piston would need to be stop while 170 pounds of force is still acting upon it. Buffering is a must even at this low pressure. Vent holes must also be drilled at the muzzle to release the back pressure at the end.

I neglected to do that first before doing the first test shots. Buffering was serve by a hastily made plastic bag cushion that was held at the muzzle by three clothes pegs duct taped on tightly. At 40 psi, the sabot rip apart the clothes pegs and flew out along with the dowel i was using as the projectile.

Suffice to say, i would need to improve the setup before i can share any useful findings. I would return as soon. Until then, feel free to criticize or lament my venture.

Posted: Tue May 28, 2013 12:21 pm

by jackssmirkingrevenge

This is quite an old concept in firearms:

Here's a very interesting document about some experiments done in the sixties for such a weapon:

http://www.dtic.mil/cgi-bin/GetTRDoc?AD=AD0334799

Some forum links that might be of interest:

http://www.spudfiles.com/forums/barrel- ... 19302.html

http://www.spudfiles.com/forums/supress ... 23298.html

http://www.spudfiles.com/forums/sprung- ... 23017.html

http://www.spudfiles.com/forums/pneumat ... 24525.html

Stopping the sabot even if it is very light is quite a challenge, but if you read through the above threads there are a variety of good ideas when it comes to buffers.

Posted: Tue May 28, 2013 3:00 pm

by Brian the brain

Posted: Tue May 28, 2013 3:55 pm

by jackssmirkingrevenge

Would you believe I deliberately didn't include that link so that you could chime in

Posted: Tue May 28, 2013 5:46 pm

by Kilash

Interesting stuff guys!

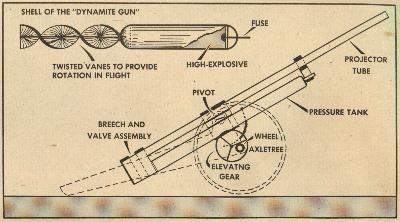

I myself was inspired by the dynamite guns used in the 1800s, basically air pistons driven by blackpowder charges for silent large calibre artillery, as well as an air gun design I seen a long time ago.

The sabot is pretty sturdy, it hit the wall a couple times on the fluke test, a few dents on the plastic part, but the intact aluminum disc is my main seal. My current sabot piston weighs in at about 21 grams. The projectile has to be at least twice as heavy to get any meaningful proportion of the total muzzle energy, but that comes at the expense of muzzle velocity.

I did the math and a 60 gram projectile would be the best compromise, which would give me a muzzle energy of around 200 foot pounds and a velocity just above 90~ m/s.

Moonbogg's post on a bungee leash on the sabot I have actually tried on a sabot for my 0.75 barrel, but I find that the leash cord sometimes jam between the barrel and the sabot, probably because the acceleration is too rapid and the cord can't get out of the way in time.

If I can find a 2 inch compression spring, that would be perfect.

Posted: Tue May 28, 2013 11:54 pm

by Kilash

Results are in, the sabot performed horribly. Firing out from a 3/4 barrel of the same length gave better muzzle velocity and energy for the same projectile. I thought it might had been the friction of the sabot, but i loosen its seal and its still performed worst.

Could it be because I'm using a 3/4" valve output while the barrel is 2"?

Posted: Wed May 29, 2013 12:42 am

by jackssmirkingrevenge

Kilash wrote:I myself was inspired by the dynamite guns used in the 1800s, basically air pistons driven by blackpowder charges for silent large calibre artillery

Not quite the same concept, I'm assuming you mean the Sims-Dudley dynamite gun:

This is not quite the same thing, it's basically a solid fuel version of a springer air rifle. The black powder charge drives a piston which compresses air in the chamber, and it is this compressed air which is then used to fire the projectile like a conventional pneumatic.

If I can find a 2 inch compression spring, that would be perfect.

Not really, with the sort of forces involved you would knacker it fairly quickly. What you want is some sort of

air cushion.

This is pretty much how pneumatic nailguns are prevented from hammering themselves to pieces:

Could it be because I'm using a 3/4" valve output while the barrel is 2"?

Clearly. The bigger barrel obviously has more area for the air to push on, but since the air has more place to expand, it's at lower pressure.

Posted: Wed May 29, 2013 12:01 pm

by Kilash

What you suggest for a valve?

Posted: Wed May 29, 2013 2:05 pm

by Brian the brain

Would you believe I deliberately didn't include that link so that you could chime in

I thought you left it out to

tease me into joining the discussion..

I suggest a fast opening valve as close to 2" as possible.

Either factory- or homemade.

I suggest using a sabot material that can absorb shock without deforming permanently, like solid rubber.

The aircushion is hard to get right.

With sufficient travel to ease the sabot to a stop,it could take up a lot of barrel length, rendering that end useless for excelleration purposes.

Increase the surfacearea to counter the need for travel.. and pressure inside the buffer will rise too quickly and the cushion or the sabot will suffer damage.

You need to get it just about right.

I used an arrow through a snug endcap.

That created it's own aircushion.If pressure inside that bufferzone increased to much it could simply eject the arrow faster, away from the sabot.

Like a springpiston airgun fires its projectile.

At least...that was the plan..

Posted: Thu May 30, 2013 6:19 am

by jackssmirkingrevenge

Brian the brain wrote:The aircushion is hard to get right.

With sufficient travel to ease the sabot to a stop,it could take up a lot of barrel length, rendering that end useless for excelleration purposes.

By air cushion I mean something like psycix had mentioned in your launcher thread, similar to the nailgun illustrated above:

That being said, there is a lot of merit to the idea of using a very low C:B ratio, if you take it to extreme you would not even need a physical stop at the muzzle to prevent the sabot/piston flying out.

The issue as you pointed out is that you would either need a tiny chamber or a very long barrel to achieve the effect.

There is a way around this though to preserve compactness - simply fit a large diameter sleeve and porting to the barrel.

The porting should be al least the equivalent to the cross sectional area of the barrel, and the volume of the barrel + sleeve in the case of a pneumatic should be at least the same as (chamber volume x [operating pressure/atmospheric pressure])

No need for baffles, but the length covered by the porting should be less than the length of the sabot, so no gas can escape past it as it goes through the porting.

The projectile should be a loose fit in the sabot in order to separate cleanly as soon as it starts to decelerate, while the sabot should be as snug a fit as possible in the barrel.

Posted: Tue Jun 04, 2013 11:40 am

by Brian the brain

By air cushion I mean something like psycix had mentioned in your launcher thread, similar to the nailgun illustrated above:

I know.

but if it seals perfect, the edges might chip or get deformed.

With a bit of room for error to prevent this it won't be very effective with a short stroke.

It could all be worked out eventually, but going with rubber seems simpler.

The barrelshroud could also be replaced by a T, a hose and a bottle as buttstock type of thing.

Seems like a sudden drop in pressure would help to stop the sabot from excellerating, but it won't slow it down...

Posted: Tue Jun 04, 2013 4:04 pm

by jackssmirkingrevenge

Brian the brain wrote:The barrelshroud could also be replaced by a T, a hose and a bottle as buttstock type of thing.

Practical as usual

Brian the brain wrote:Seems like a sudden drop in pressure would help to stop the sabot from excellerating, but it won't slow it down...

If the volume is big enough, it will stop it.

I have done some testing in that regard, quite by accident, it's rather amazing

will email you a video.

In the meantime, I'm contemplating making a hybrid replica of this little baby, the Yugoslav

"Self Suppressing Unit"underwater pistol:

It fires a steel tipped dart at high subsonic speed that can apparently penetrate a SCUBA tank with "only" 110 bar, that's within the realm of advanced spudders...

Posted: Sun Jun 09, 2013 8:07 am

by Brian the brain

Those are selfcontained cartridges...

And being made for underwater use...I imagine the entire barrel being an aircushion...

See the O-ring around the arrow?

just a lightweight captive sabot.

I suggest calling those cabbot from now on..

No chipping and deforming...

The pressure-buildup would probably just help to eject the arrow...

reducing the diameter of the tail would make sure it does.

Two birds, one stone.

Posted: Mon Jun 10, 2013 12:48 am

by jackssmirkingrevenge

Brian the brain wrote:Those are selfcontained cartridges...

And being made for underwater use...I imagine the entire barrel being an aircushion...

See the O-ring around the arrow?

Since it's meant to be fired underwater, clearly that space cannot be filled with liquid because it would have a significant effect on performance. I think the cushioning effect is serendipitous after the principal concern of having the piston accelerate in air rather than water is addressed.

just a lightweight captive sabot.

I suggest calling those cabbot from now on..

Brian le brain, le roi de portmanteaux

No chipping and deforming...

The pressure-buildup would probably just help to eject the arrow...

reducing the diameter of the tail would make sure it does.

Thinking about it, if the whole system is airtight, I doubt the cabbot (lol) is actually in contact with the dart after a couple of cm of travel, because of the internal pressure generated.

Just thinking aloud here, for a pneumatic the cabbot could be a QDV piston...

Posted: Mon Jun 10, 2013 10:20 am

by dart guy

when i get back from paint i will have an awsome pic for you that will probably give you a high fps shot